Grinding head self-floating stone grinding and polishing machine

A polishing machine and grinding technology, used in grinding/polishing equipment, surface-polished machine tools, grinding machine parts, etc., can solve problems such as reducing production efficiency, improve production efficiency, omit adjustment, and increase sweeping The effect of sweeping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

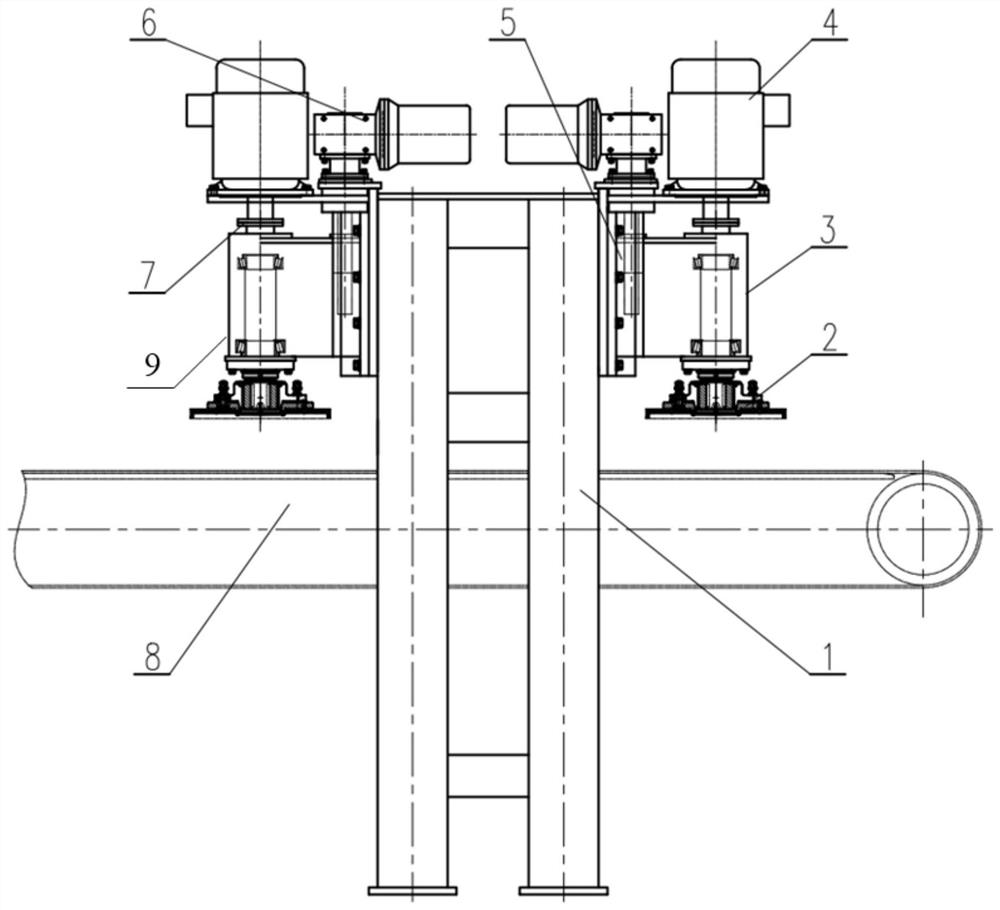

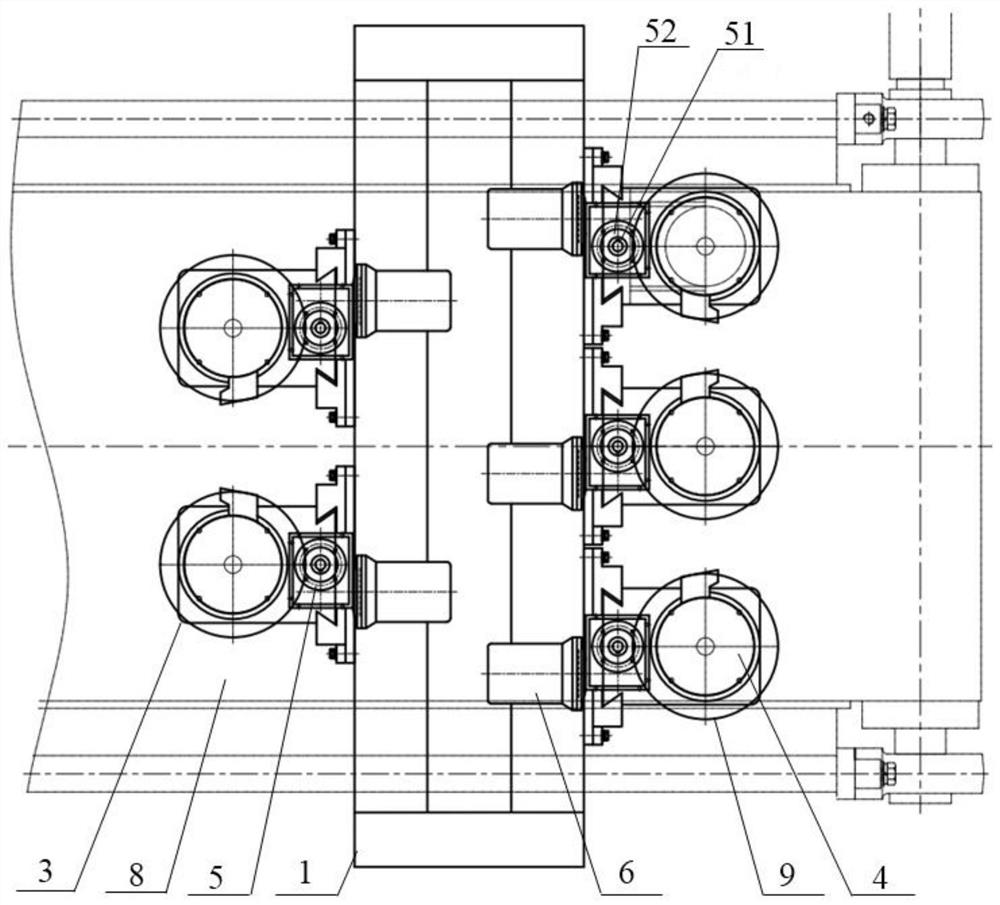

[0023] The present invention is a self-floating stone grinding and polishing machine with a grinding head, referring to figure 1 and figure 2 , including a frame 1, the two sides of the frame 1 are staggered with grinding and polishing grinding heads 9, which invisibly increases the sweeping area of the grinding head when cutting, so that the ultra-wide flat or approximately flat plate (block) material can be cut at one time Grinding and polishing can be comprehensively processed, and continuous feeding can be achieved without the need for horizontal and vertical reciprocating motion of the grinding and polishing machine.

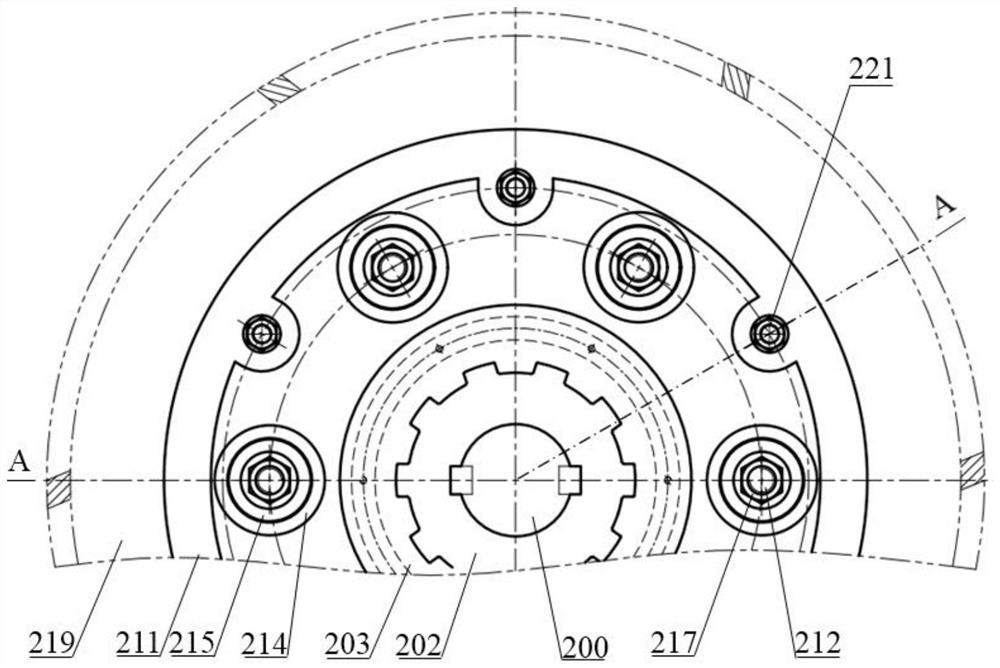

[0024] refer to image 3 , the frame 1 is connected with the grinding and polishing grinding head 9 through the lifting screw nut mechanism 5, the grinding and polishing grinding head 9 includes a self-floating grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com