Digitally controlled curved electric spark grinder

An electric spark and curved surface technology, applied in circuits, electric processing equipment, clamping and other directions, can solve the problems of smoothness limitation, slow processing efficiency, low efficiency, etc., and achieve the effect of improved surface quality, low cost and fast processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

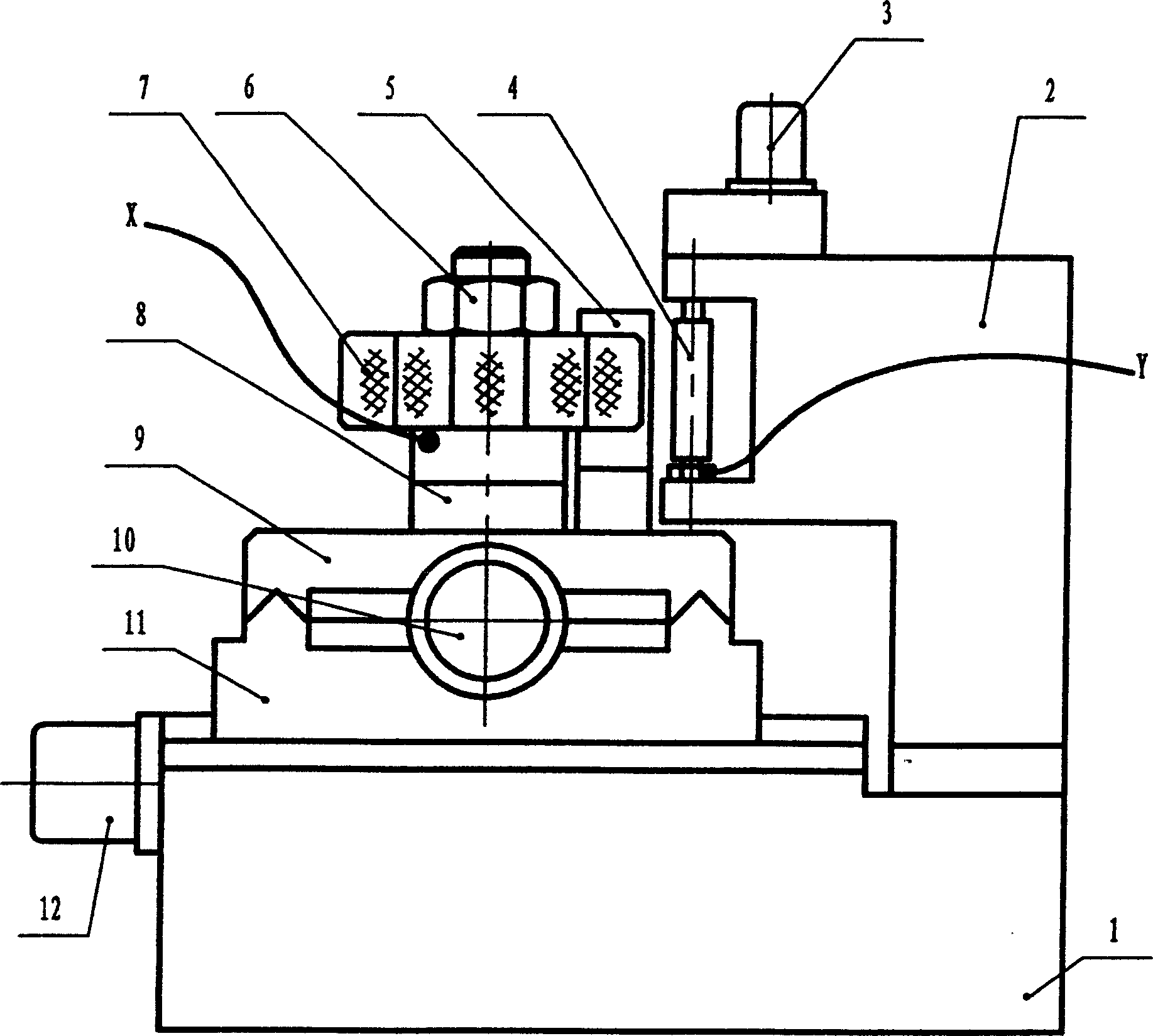

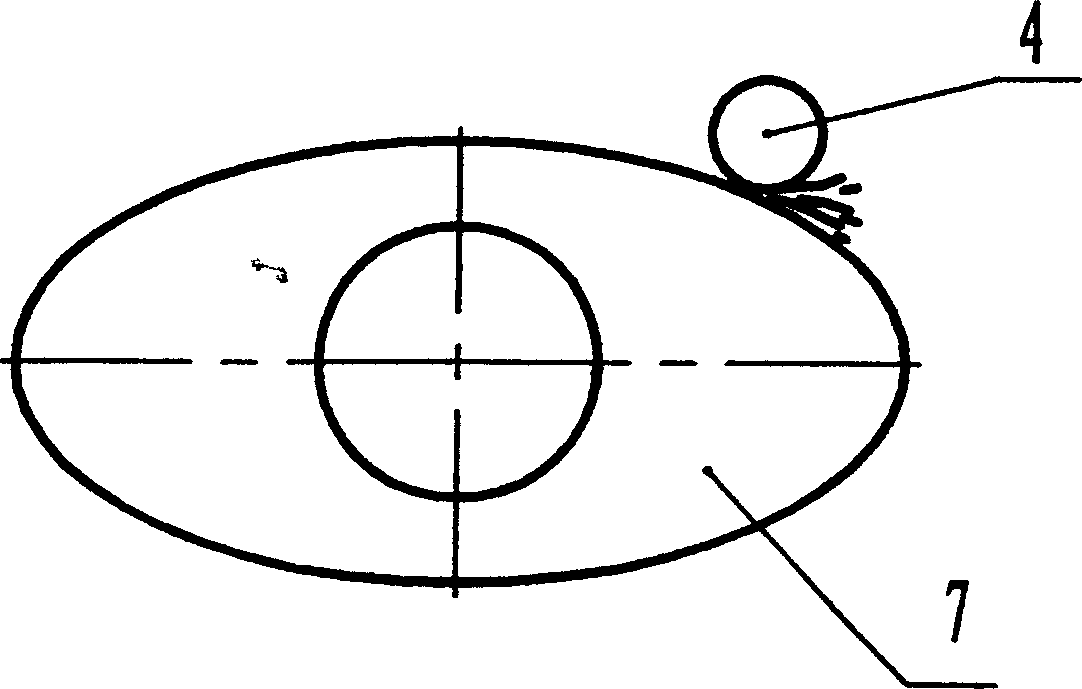

[0018] as attached figure 1 As shown, a CNC electric spark surface grinder, the bed (1) is fixedly connected with the column (2), and the protruding part of the column (2) forms a detachable rotational connection with the grinding head (4). The detachable purpose In order to facilitate the replacement of the grinding head, clamping methods such as spring clamps can be used. The grinding head (4) is driven to rotate by the rotary drive device (3); the upper and lower sides of the carriage (11) are provided with mutually perpendicular guide rails, and the guide rails below it It forms a sliding connection with the bed (1), and the upper guide rail forms a sliding connection with the worktable (9). The horizontal drive device (12) installed on the bed (1) drives the carriage to drive the workbench to move left and right. The longitudinal driving device (10) on the carriage (11) drives the workbench (9) to move back and forth; the workbench (9) is provided with an insulated workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com