Continuous drying device for powdery simple substance explosive

A technology of simple explosives and drying devices, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of non-isolated operation, long drying process cycle, and low drying efficiency, achieve isolation between operation and drying site, and shorten drying process Effect of cycle and continuous drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

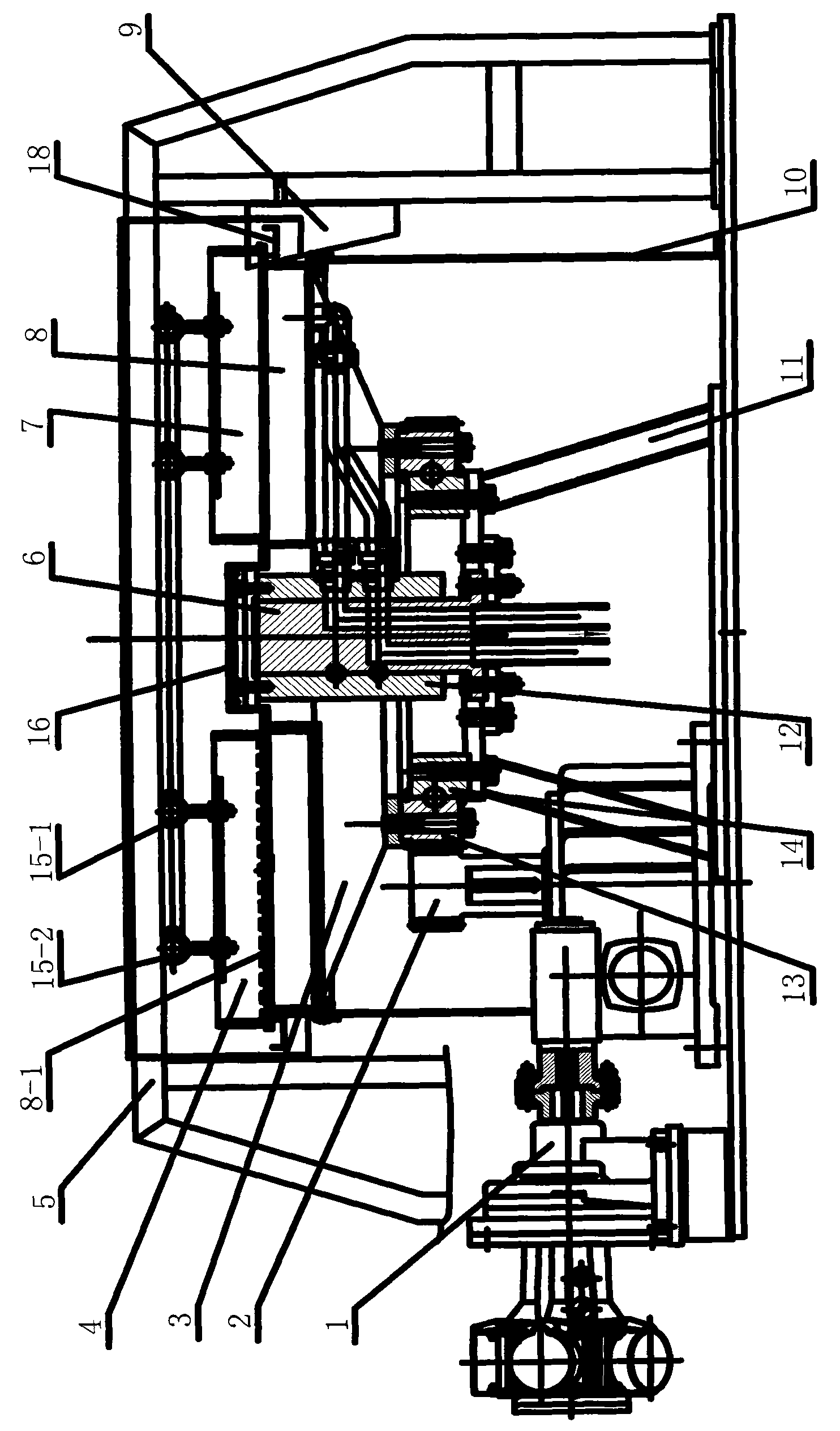

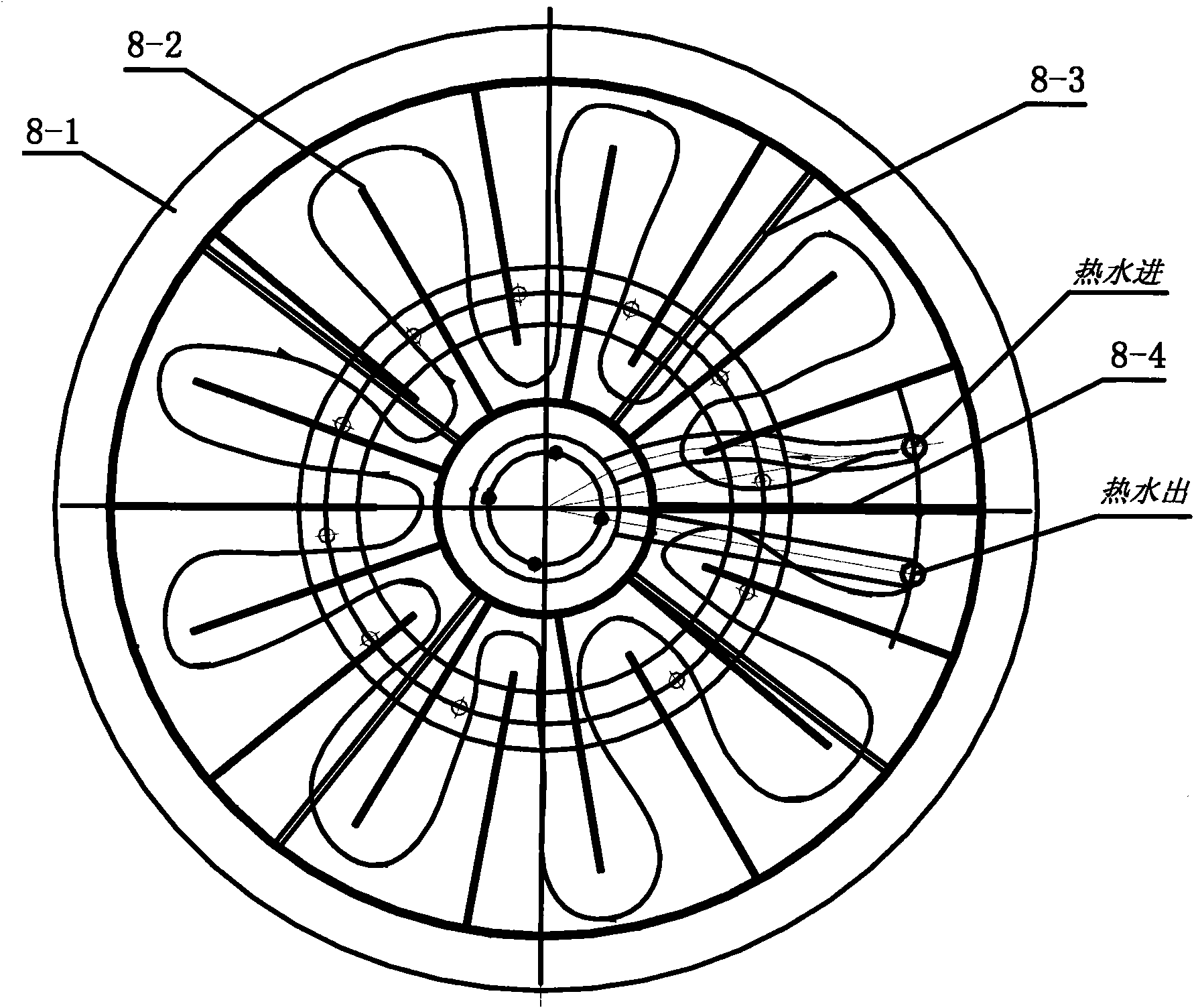

[0018] as figure 1 As shown, the preferred embodiment of the continuous drying device of the present invention includes a basic frame unit, a drive transmission unit, a static-rotation connection unit, a heat supply unit and a drying operation unit.

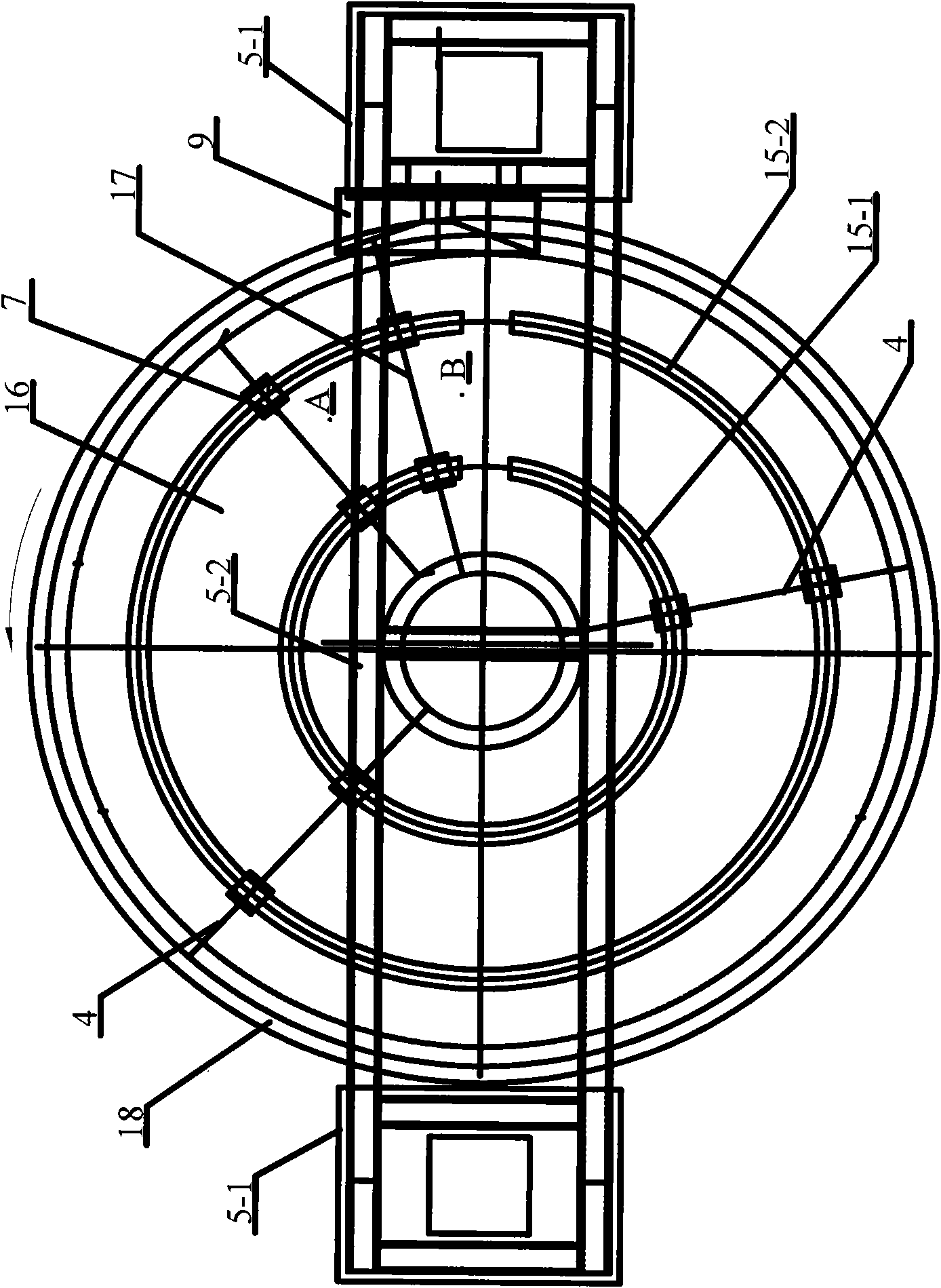

[0019] The basic frame unit includes an outer support frame body 5 , an inner support frame body 11 and a shield 10 . The outer support frame body 5 contains a base, two column frames 5-1 and a beam frame 5-2 symmetrically installed on the base, and the beam frame 5-2 is a ladder-like rectangular frame, and the two ends of its length direction are respectively fixed on two The top of a column frame 5-1. The inner support frame body 11 is a frame made of a base, a column and a top plate, and the inner support frame body is located in the middle of the two column frames and faces two be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com