Annealing apparatus

An annealing device and light-emitting element technology, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of large LED loss, reduced LED luminous amount, and reduced efficiency, so as to reduce losses and suppress the reduction of luminous amount Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

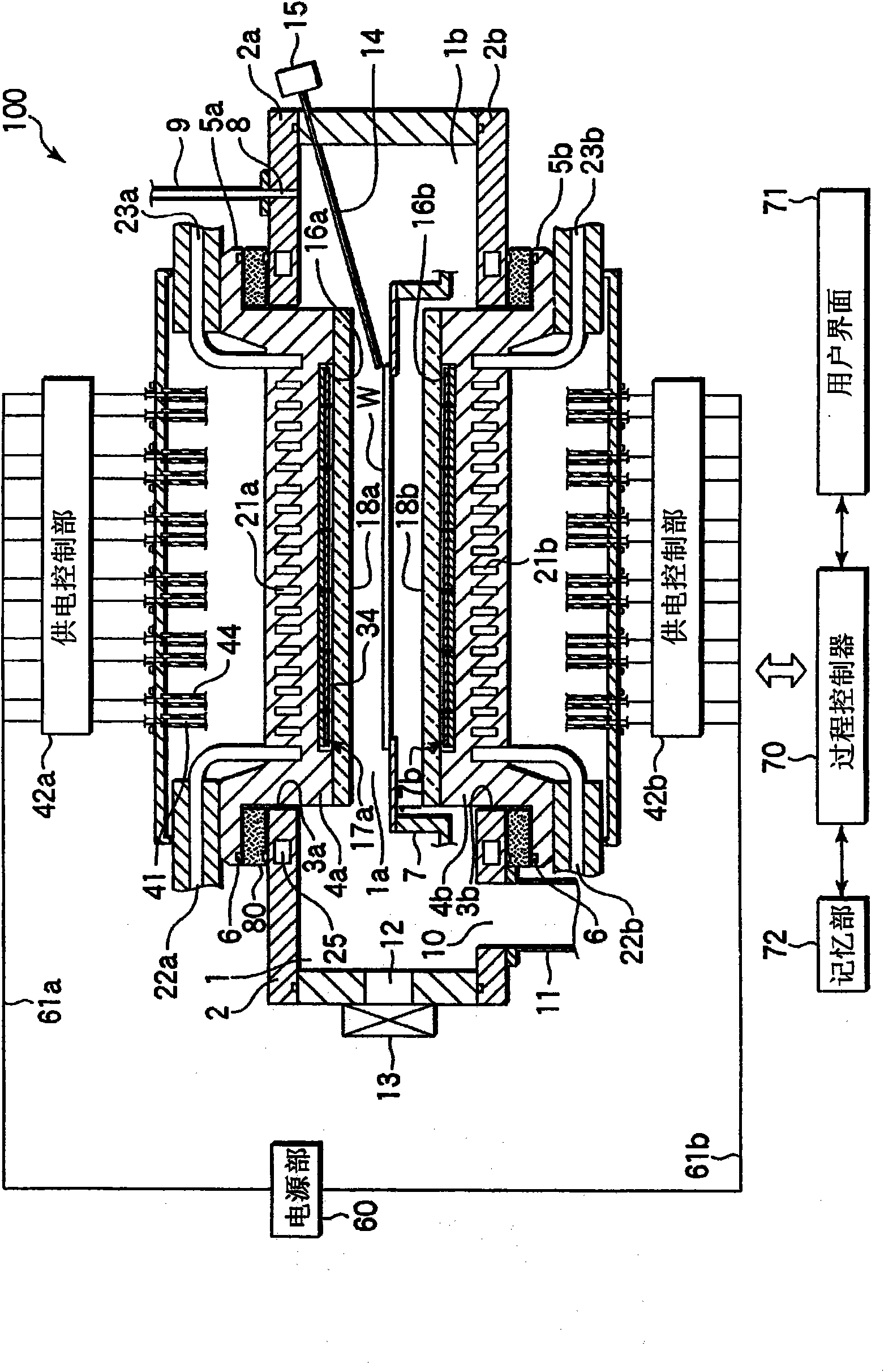

[0025] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Here, an annealing apparatus for annealing a wafer with impurities implanted on its surface will be described as an example.

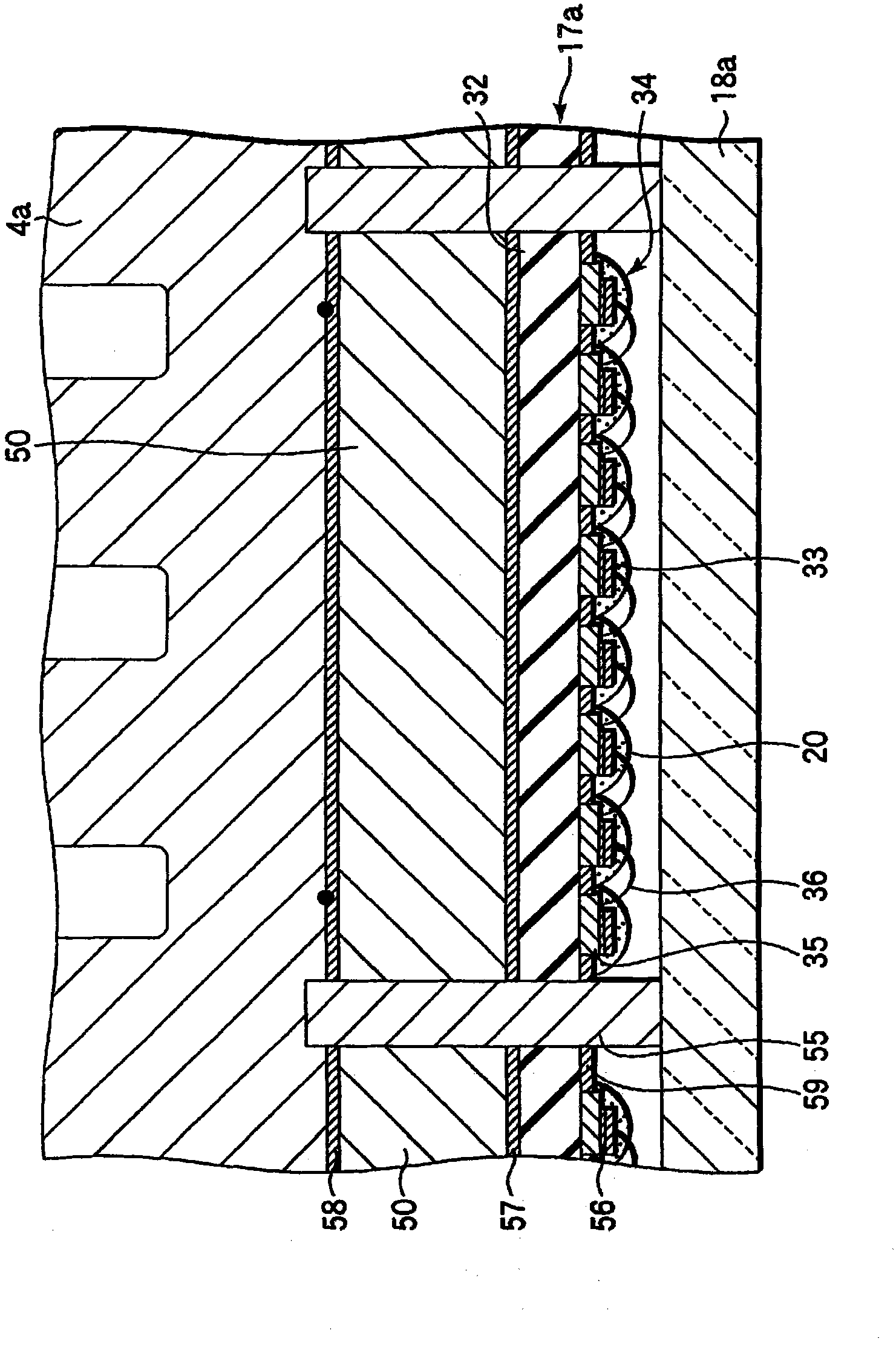

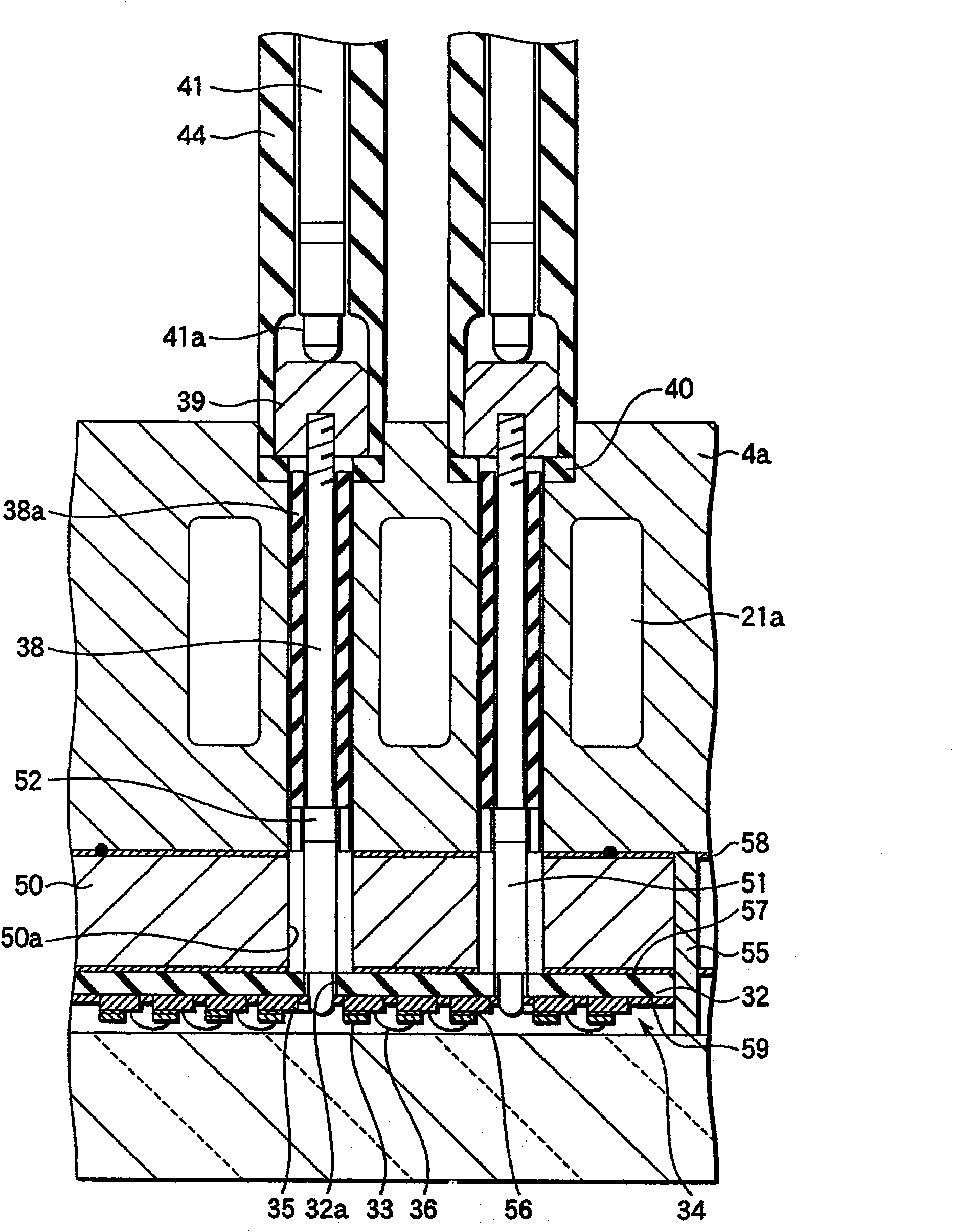

[0026] figure 1 It is a cross-sectional view showing a schematic configuration of an annealing apparatus according to an embodiment of the present invention. figure 2 yes means figure 1 An enlarged cross-sectional view of the heating source of the annealing apparatus. image 3 yes means figure 1 An enlarged cross-sectional view of the power supply portion of the LED of the annealing device.

[0027] This annealing apparatus 100 is constituted by a seal, and has a processing chamber 1 into which a wafer W is loaded. The processing chamber 1 has a columnar annealing section 1a in which a wafer W is arranged, and an annular gas diffusion section 1b provided outside the annealing section 1a. The height of the gas diffusion part 1b is higher tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com