Rocker chamber cover assembly system with respirator

A technology of rocker chamber and respirator, which is applied in the direction of machine/engine, engine components, casing, etc., can solve the problems of difficult layout of parts, complex shape and structure, and large space occupation, so as to achieve a simple and reasonable design structure and save peripheral space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

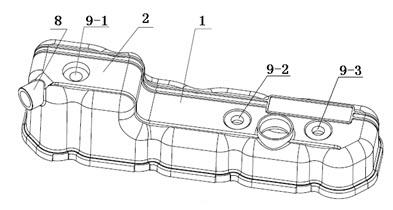

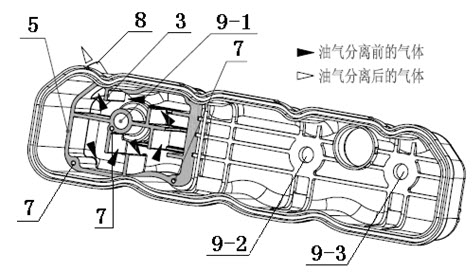

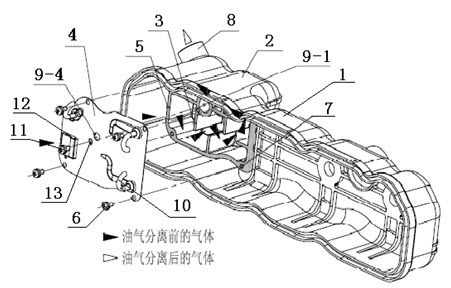

[0011] Hereinafter, the structural principle of the present invention will be further described with reference to the drawings and embodiments. The rocker arm chamber cover assembly system with respirator has a structure that the rocker arm chamber cover body 1 is provided with a respirator working chamber 2 ( figure 1 ), a labyrinth space 3 is provided in the working chamber 2 of the respirator, the working chamber cover 4 of the respirator is arranged in the rocker cover body, and the working chamber cover 4 of the respirator is assembled on the sealing surface 5 of the working chamber of the respirator, using 5 The screw 6 is fastened to the screw hole 7 on the rocker cover body for sealing ( figure 2 ). There is a respirator air outlet 8 at the position of the respirator working chamber of the rocker chamber cover, which passes through the three assembly bolt holes 9-1~9-3 on the rocker chamber cover body 1 and the respirator working chamber cover 4. The fourth assembly bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com