Fluidized bed distribution plate for production of tetrachloro isophthalonitrile

A technology of tetrachloroisophthalonitrile and distribution plate, which is applied in the field of fluidized bed distribution plate, can solve problems such as poor state of plate separation, improve the state of gas-solid fluidization, improve the fluidization state, and lengthen the service period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

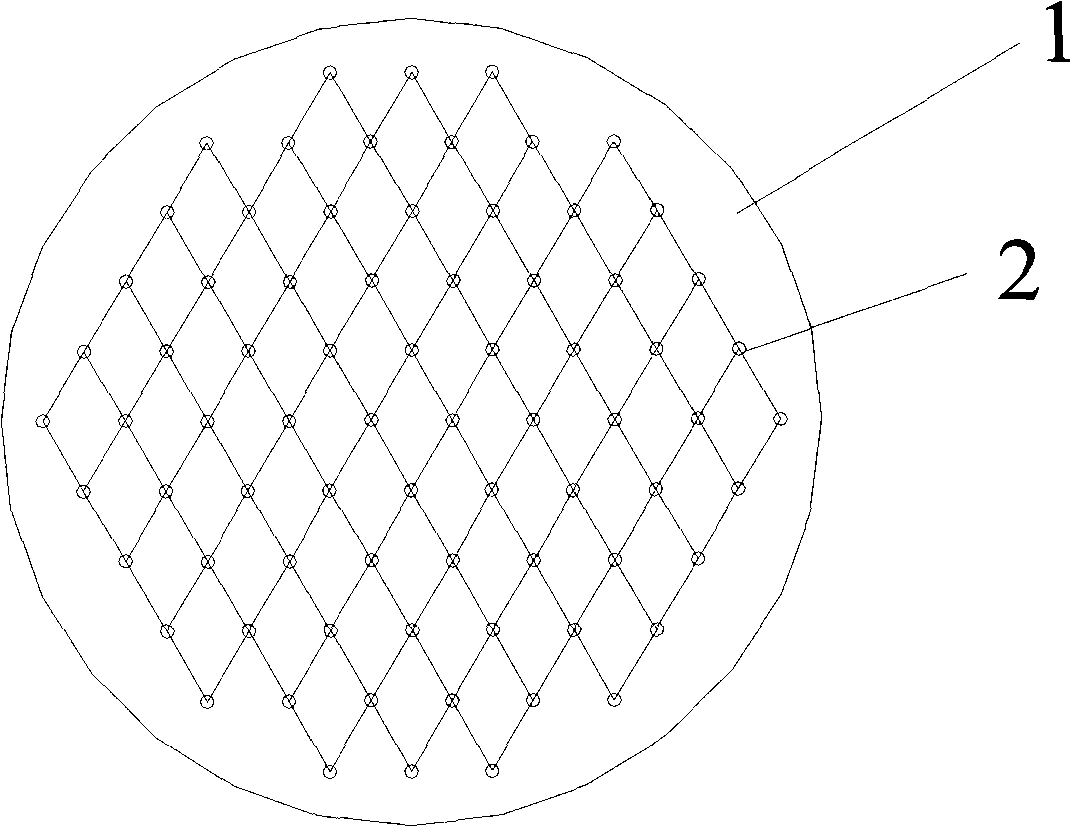

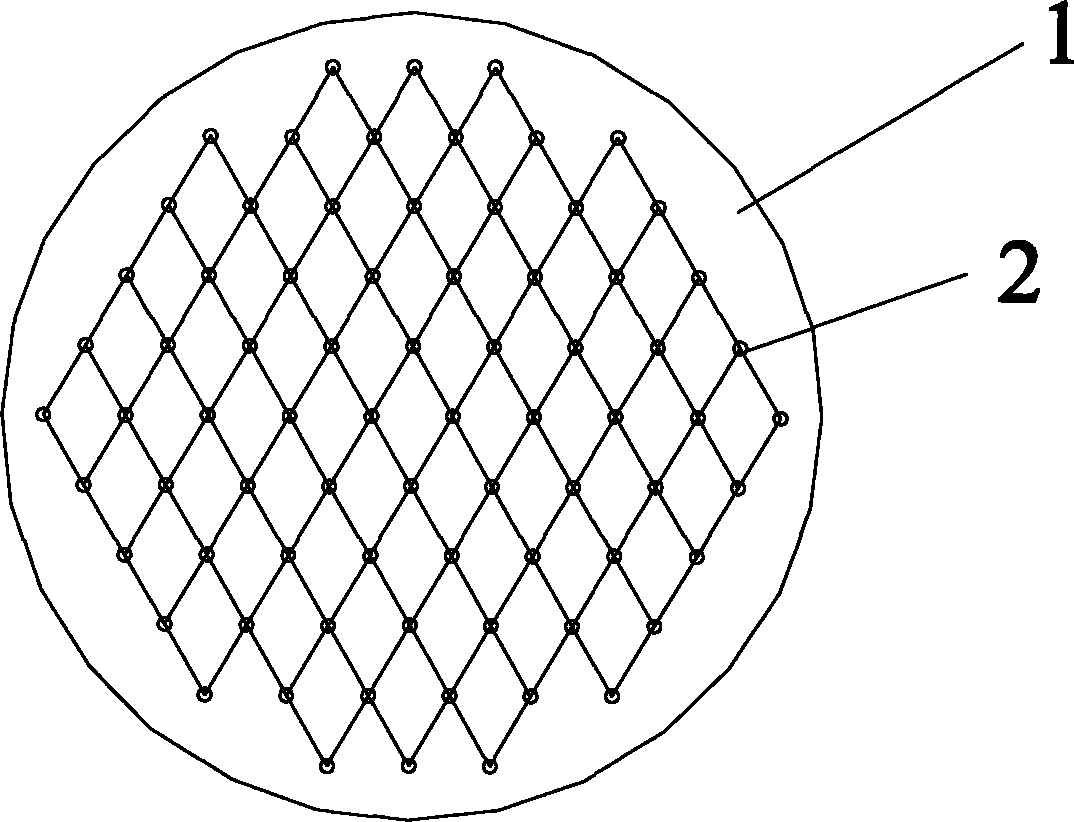

[0015] A kind of tetrachloroisophthalonitrile production fluidized bed distribution plate 1, this distribution plate 1 is circular, and the diameter of distribution plate 1 is 1200mm, and the middle area of distribution plate 1 has air hole 2, and the diameter of air hole 2 is 20mm, the air holes 2 are arranged in a regular triangle on the distribution plate, the angle between the two sides is 60°, and the distance between the horizontally distributed air holes 2 is 120mm, which is arranged corresponding to the tubes below, and the opening ratio of the distribution plate 1 is 2.0% , the air velocity through the board is controlled at 0.2m / s. The distribution plate 1 of the fluidized bed overcomes the gas distribution that is limited to about 0.5m above the sub-plate by ordinary distribution plates, solves the phenomenon of channel flow, pulse and blockage, and can break the flow of large bubbles at the same time, resisting the merging and growth of bubbles, thereby improving ...

Embodiment 2

[0017] A fluidized bed distribution plate for the production of tetrachloroisophthalonitrile, the distribution plate is circular, the diameter of the distribution plate is 1100mm, there are air holes in the middle area of the distribution plate, the diameter of the air holes is 15mm, and the air holes are on the distribution plate Arranged in an equilateral triangle, the angle between the two sides is 60°, the distance between the horizontally distributed air holes is 120mm, which is arranged corresponding to the tubes below, the opening rate of the distribution plate is 1.0%, and the gas velocity through the plate is controlled at 0.1m / s. The distribution plate of the fluidized bed overcomes the gas distribution that is limited to about 0.5m above the sub-plate by ordinary distribution plates, solves the phenomenon of channel flow, pulse and blockage, and at the same time breaks the flow of large bubbles and resists the merging and growth of bubbles, thereby improving gas-s...

Embodiment 3

[0019] A fluidized bed distribution plate for the production of tetrachloroisophthalonitrile, the distribution plate is circular, the diameter of the distribution plate is 1300mm, there are air holes in the middle area of the distribution plate, the diameter of the air holes is 30mm, and the air holes are on the distribution plate Arranged in an equilateral triangle, the angle between the two sides is 60°, the distance between the horizontally distributed air holes is 120mm, which is arranged correspondingly to the tubes below, the opening rate of the distribution plate is 3.0%, and the gas velocity through the plate is controlled at 0.2m / s. The distribution plate of the fluidized bed overcomes the gas distribution that is limited to about 0.5m above the sub-plate by ordinary distribution plates, solves the phenomenon of channel flow, pulse and blockage, and at the same time breaks the flow of large bubbles and resists the merging and growth of bubbles, thereby improving gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com