Motor cooling by feeder exhaust air

A waste gas and continuous paper technology, applied to printing machines, rotary printing machines, general parts of printing machinery, etc., can solve problems such as troublesome liquid circuits, small structural space, structural problems, etc., achieve effective cooling, save cooling devices, improve Derived effect of loss power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

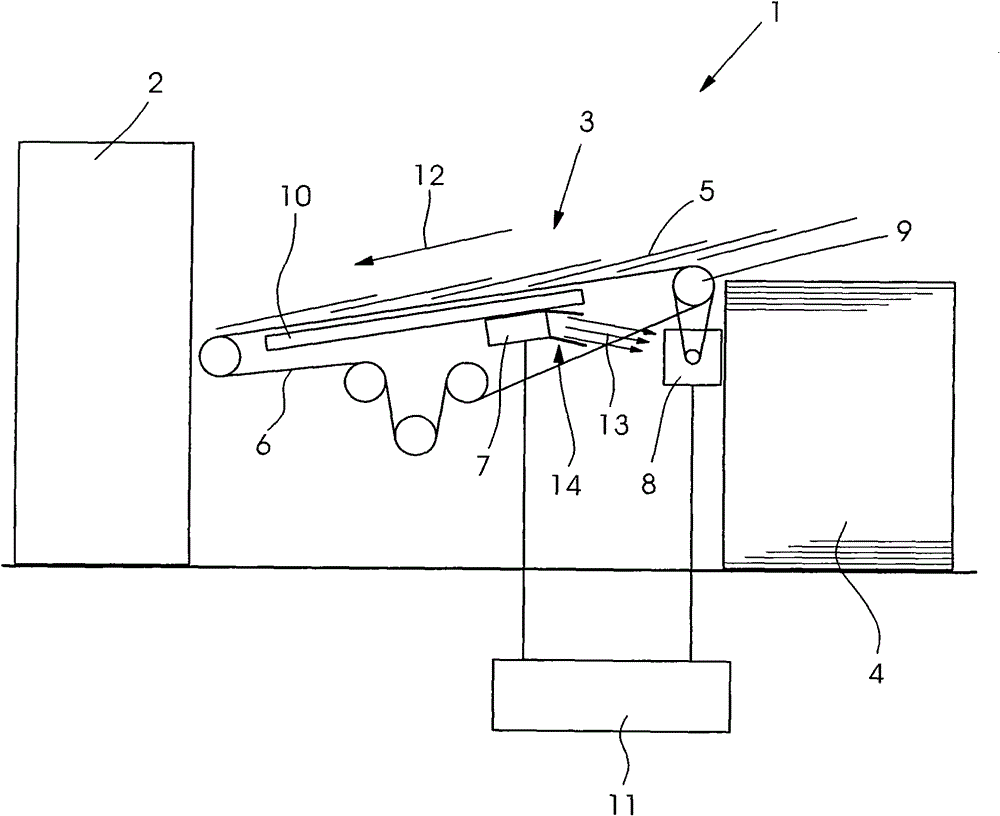

[0016] The sheet-fed printing press 1 has a plurality of printing units 2 , wherein the first printing unit 2 is supplied with a printing material 5 in sheet form via a feeding table 3 . The sheets 5 are removed from the paper stack 4 by means of a suction device (not shown here) and deposited in scales on the suction belt 6 . In this case, the speed of the suction belt 6 must correspond to the printing speed in the printing unit 2 . In the case of the sheet feeding table 3 shown in the figure, the drive of the suction belt 6 takes place by means of a drive motor 8 for said suction belt. For this purpose, the drive motor 8 is connected via a belt drive to the suction belt drive roller 9 and thus can move the suction belt 6 . The suction belt 6 is guided around a suction chamber 10 which continuously generates a vacuum and thus holds the scaly sheet 5 firmly on the perforated suction belt 6 . At the end of the sheet feeding table 3 , viewed in the sheet transport direction, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com