Method for draining gas of highly gassy coal mine

A gas drainage and gas technology, applied in the field of coal mining, can solve the problems of slow drainage, low efficiency and high cost, and achieve the effect of efficient gas drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

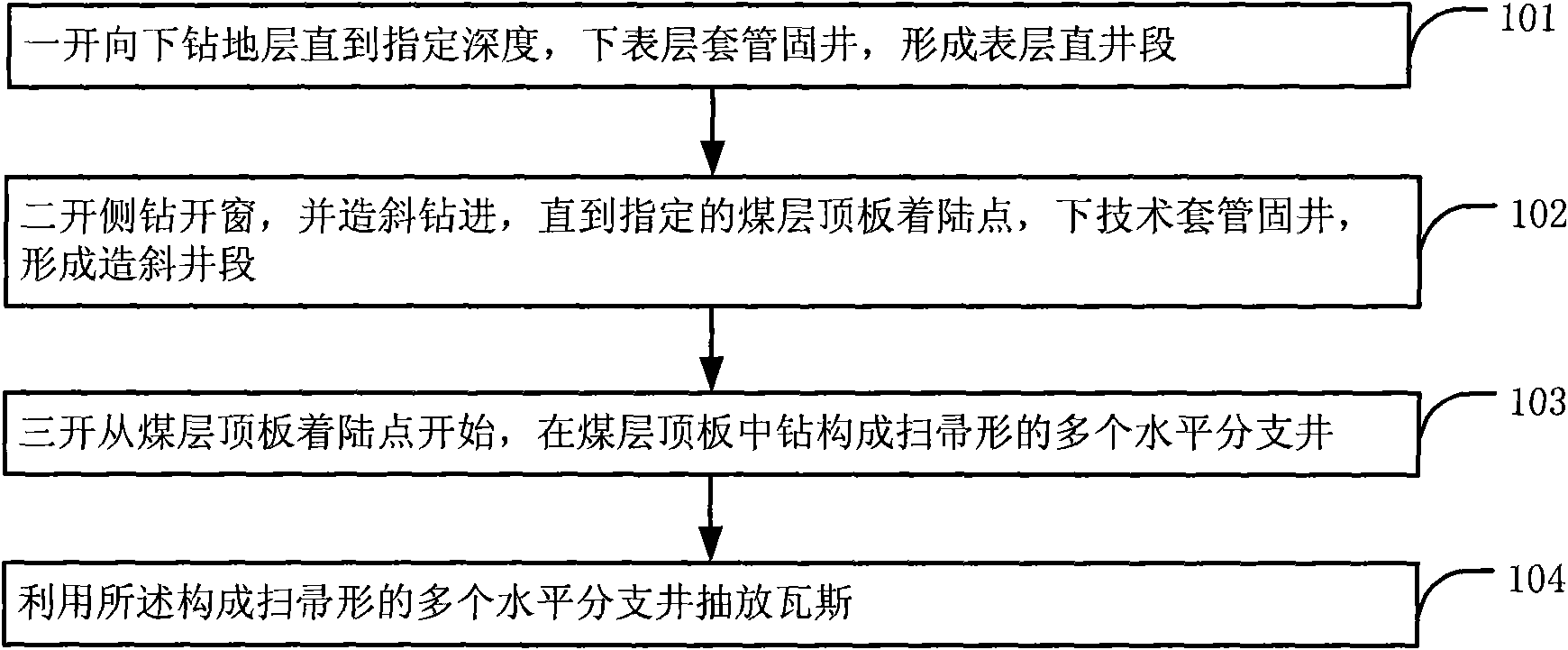

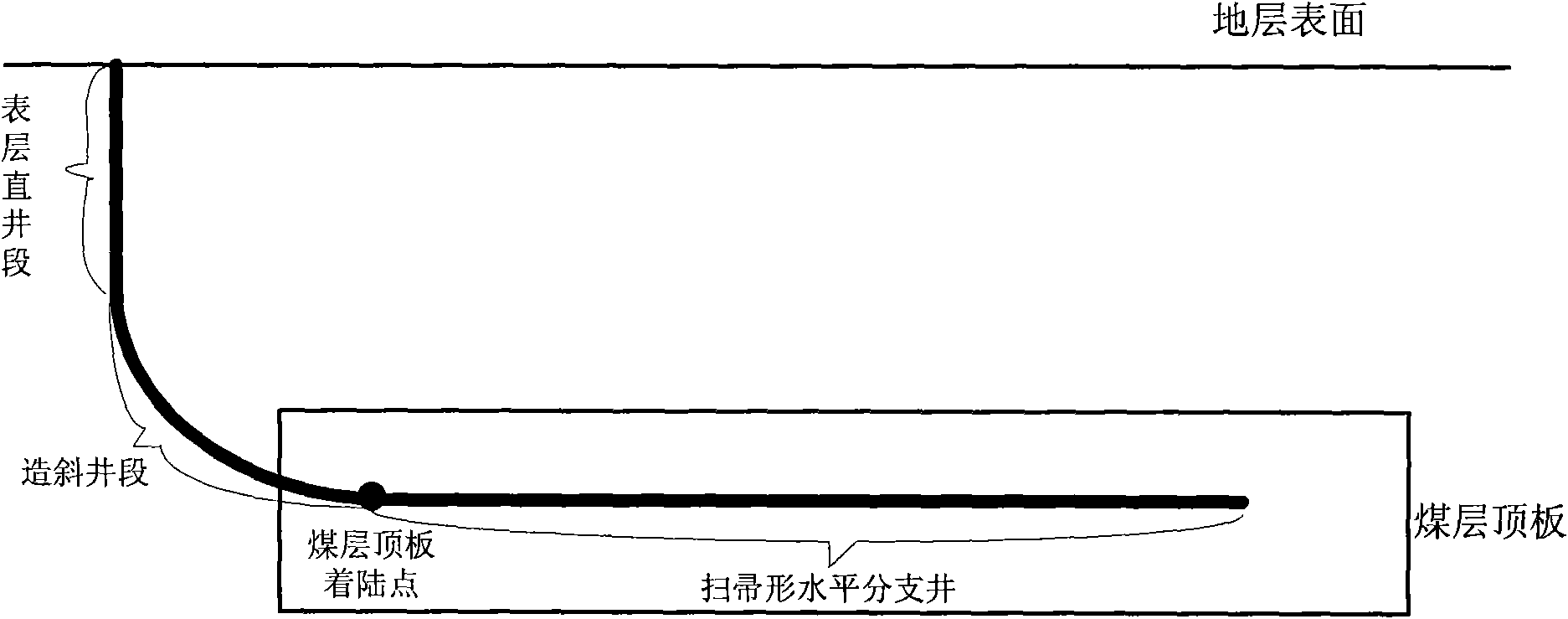

[0020] figure 1 It is a gas drainage method of high gas coal mine in the present invention. like figure 1 As shown, the method includes the following steps:

[0021] Step 101 , drill down the formation until the specified depth, and cement the casing in the lower layer to form a vertical well section in the surface layer.

[0022] In this step, a rotor in the field of oil drilling rigs can be used to drill down through the soft shallow formation.

[0023] Step 102 , the sidetracking is performed to open the window, and the deflection drilling is carried out until the landing point of the specified coal seam roof is reached, and the technical casing is cemented to form the deflection well section.

[0024] In this step, the landing point of the roof of the coal seam is pre-specified, so directional drilling is performed at the second opening, sidetracking to open the window and drilling to the destination.

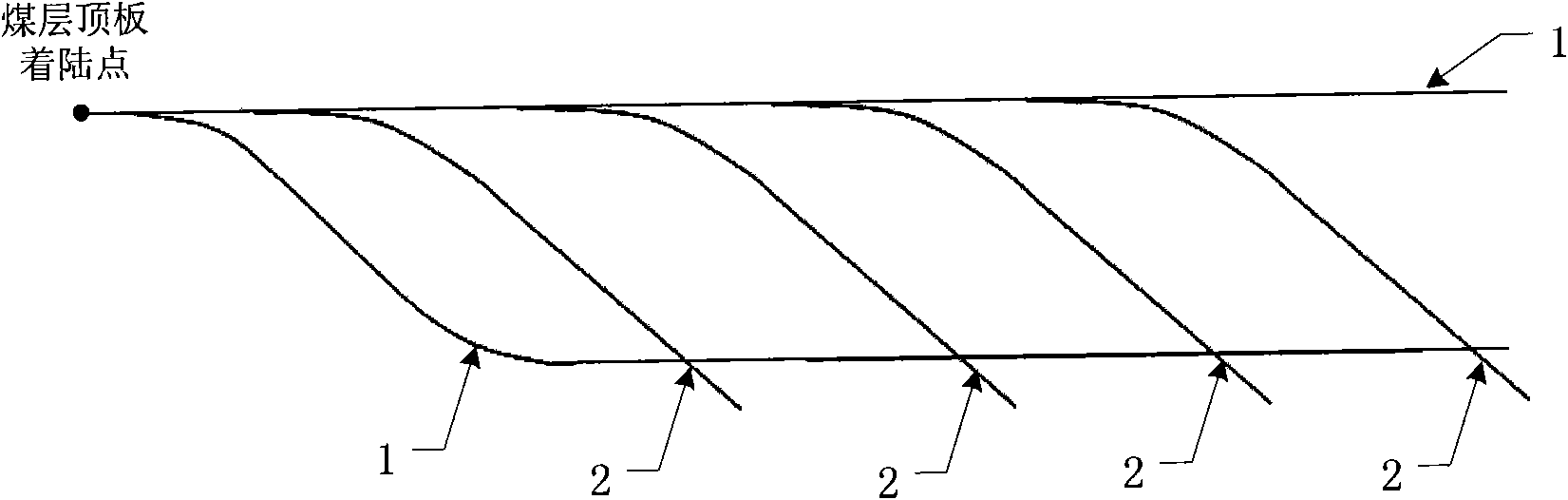

[0025] Step 103, starting from the landing point of the roof of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com