Double-rack flat gate valve for cement industry

A flat gate valve, cement industry technology, applied in sliding valves, valve details, valve devices and other directions, can solve the problems of poor piston rod stability, high manufacturing costs, long strokes, etc., to achieve smooth movement, compact structure, and less wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

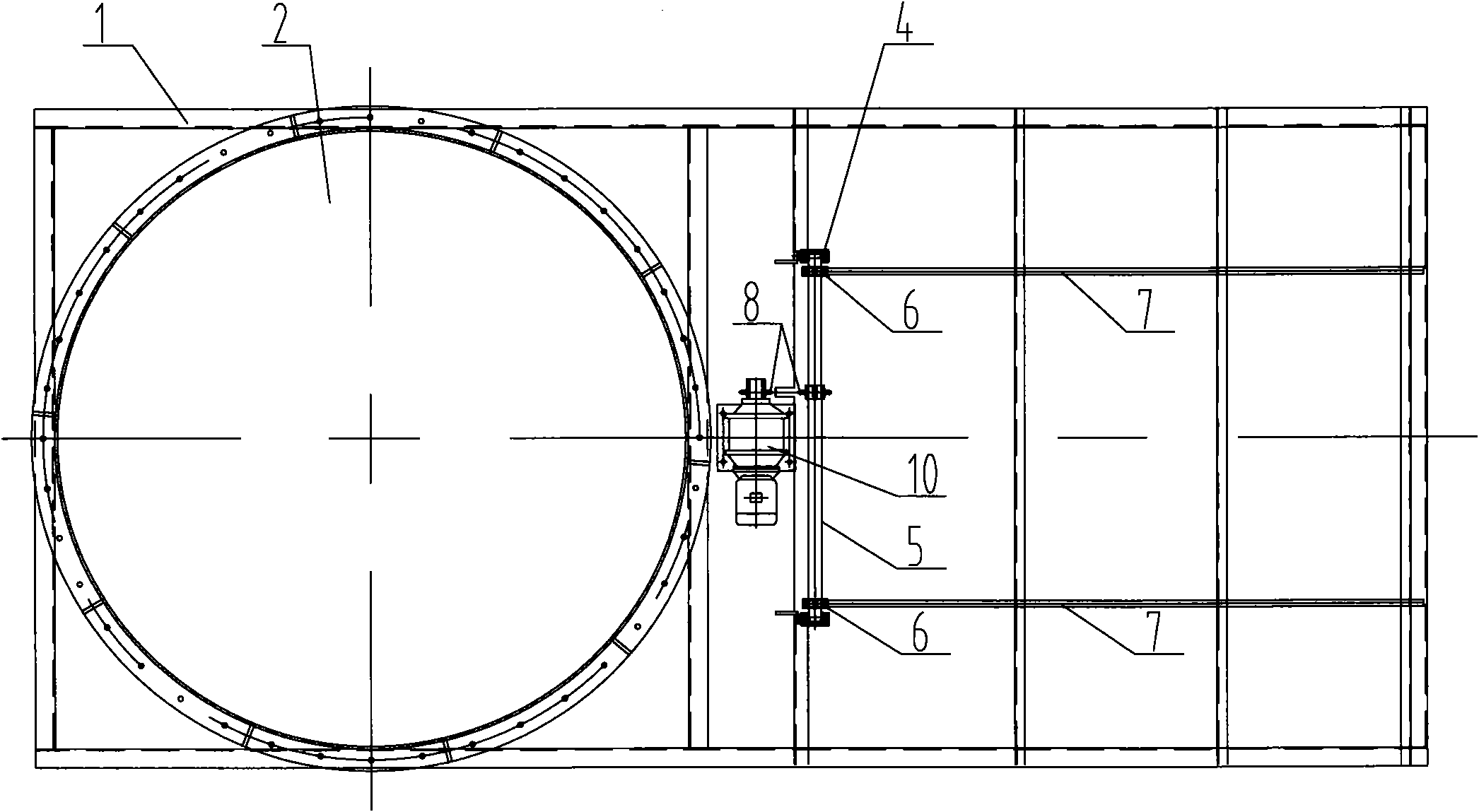

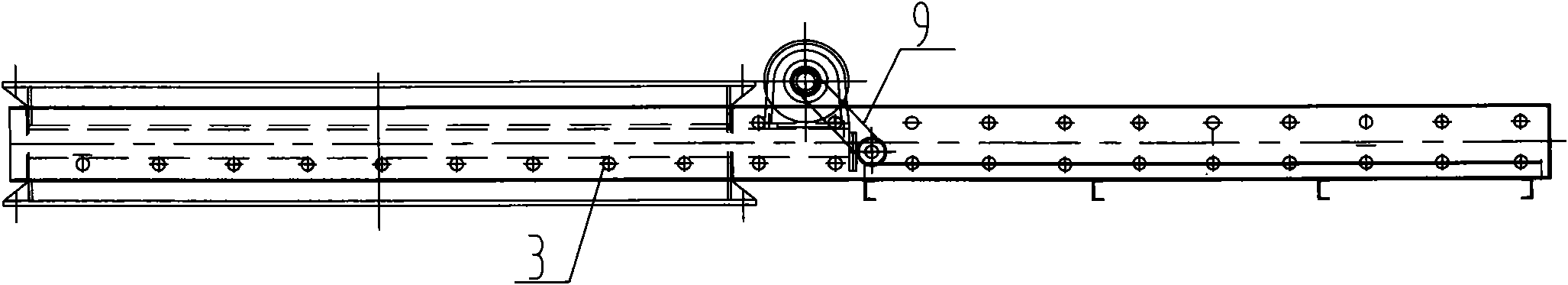

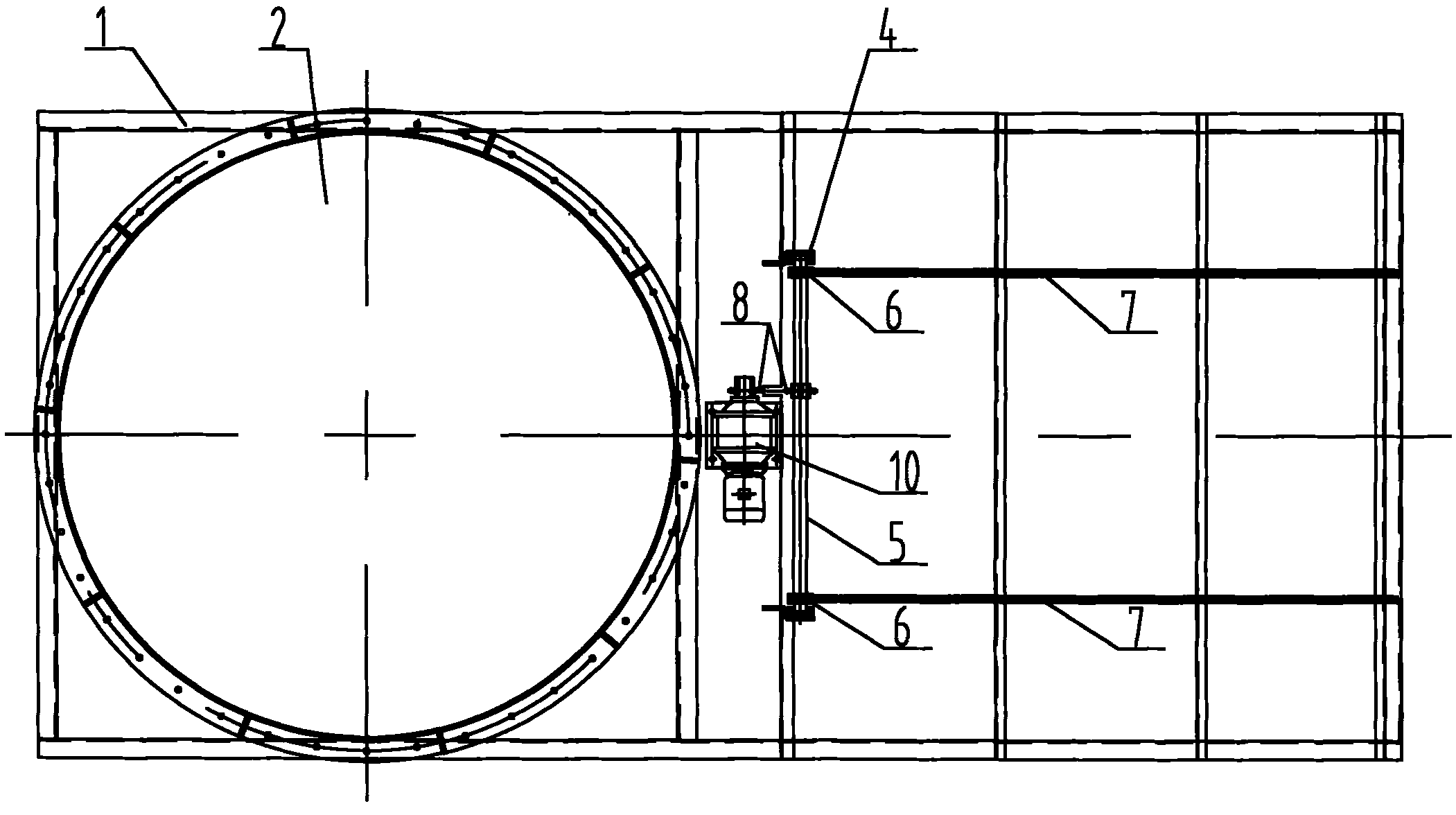

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0013] Such as figure 1 and figure 2 Shown: a double rack flat gate valve for cement industry, including valve body 1, valve plate 2, guide wheel 3, transmission shaft 5, gear 6, rack 7, sprocket 8, industrial chain 9 and electric reducer 10 , the electric reducer 10 is fixed on the valve plate 2, the guide wheel 2 is arranged under the valve plate 2, two rows of racks 7 are installed on the valve body 1, and the electric reducer 10 and the drive shaft 5 are respectively A sprocket 8 is installed, and the two sprockets 8 are connected by an industrial chain 9. Two gears 6 that can move along the tooth bar 7 are installed on the transmission shaft 5 . The transmission shaft 5 is supported by a rolling bearing 4, the two rows of racks 7 are fixed on the valve body 1 parallel and symmetrical to the center line of the valve body 1, and the valve plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com