Rotary multi-way switching valve

A multi-channel switching and rotary technology, which is applied in the direction of multi-way valves, sliding valves, valve details, etc., can solve the problems of inability to realize multi-channel multi-state control, restricting the number of valve ports, and inability to realize refrigerator refrigerant combinations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

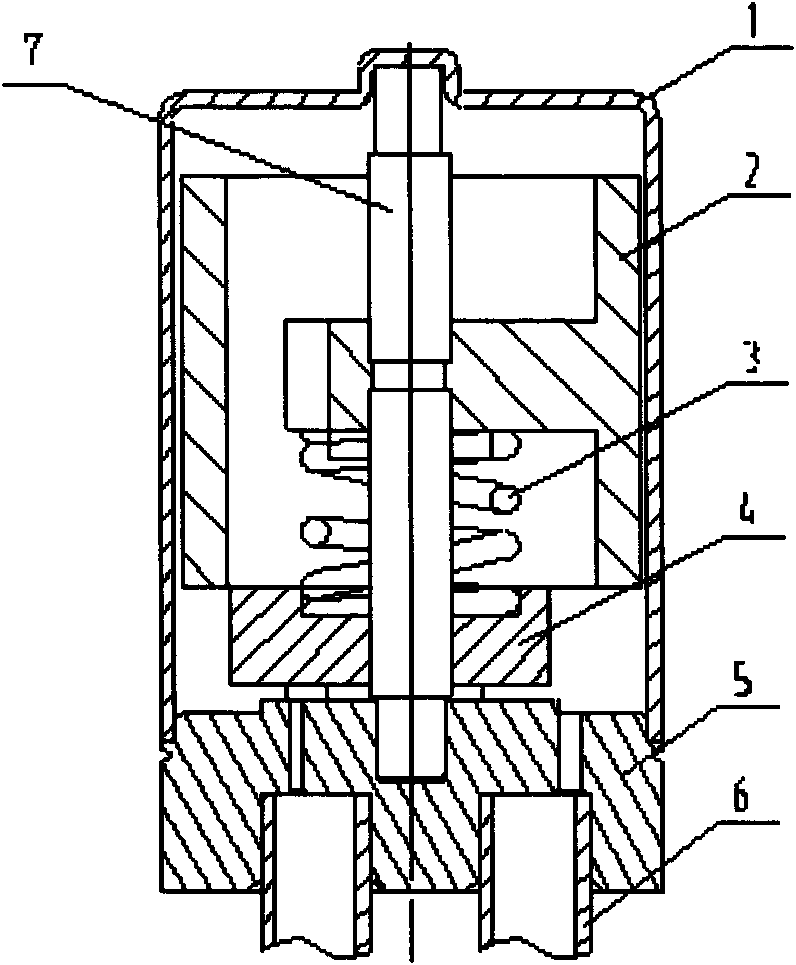

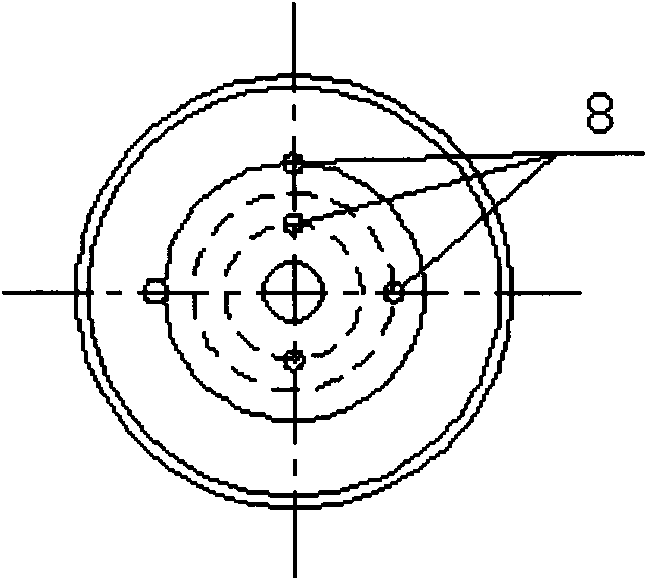

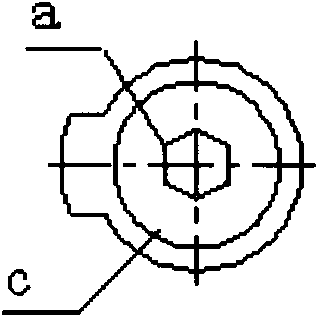

[0016] Such as figure 1 As shown, a rotary multi-way switching valve includes an outer cover 1, a shaft 7, a rotor 2, and a valve seat 5 at the lower part of the rotor. The rotor 2 is sleeved on the shaft 7 and a slider 4 is provided on the lower end surface of the rotor 2. The upper end surface of the valve seat 5 is provided with valve ports 8 communicating with the inlet and outlet connecting pipes 6 on multiple concentric circles, and at least two valve ports are on the same radial direction, and one or more valve ports are provided on each circumference, sliding The axial bottom end surface of the block 4 is provided with at least two boss planes b with different radii that are matched and sealed with the corresponding valve ports. Stop block, the switching valve is driven by a stepping motor, the rotating magnetic field force generated by the electronic coil of the stepping motor acts on the rotor 2, and the rotor 2 transmits the rotational torque to the slider 4 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com