Lyophilizer

A technology of freeze-drying machine and freeze-drying box, which is applied in the field of freeze-drying machines, can solve the problems of cumbersome operation, complex structure, poor equipment correlation, etc., and achieve the effect of good effect, good integrity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

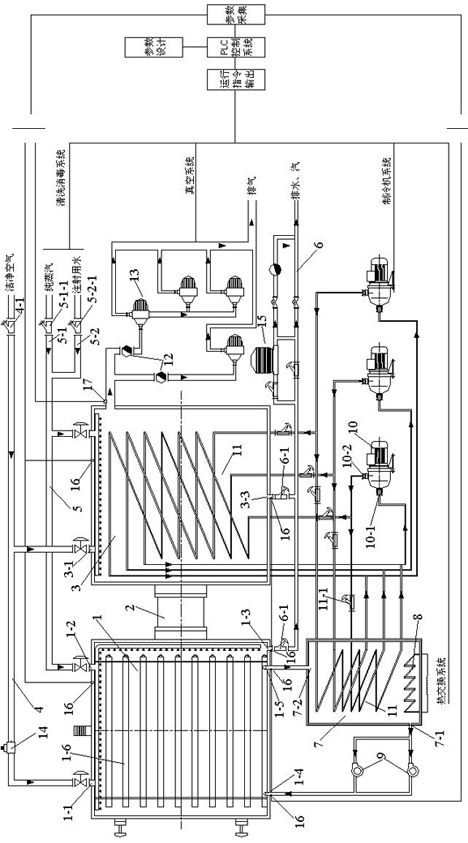

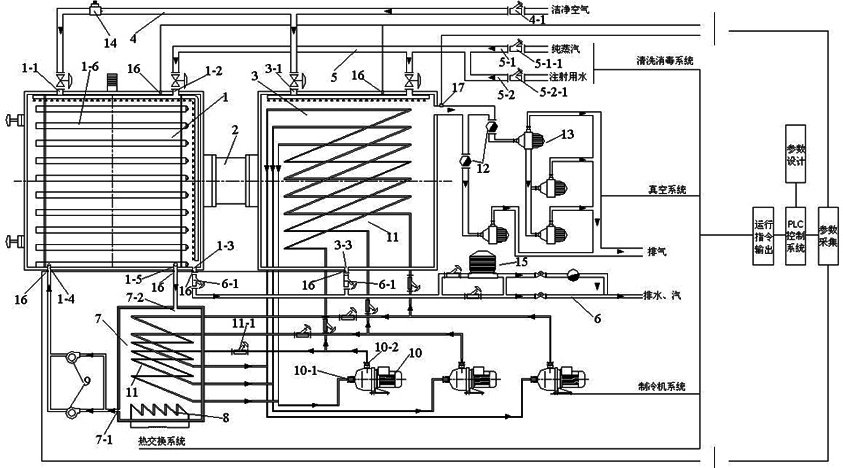

[0007] refer to figure 1 , a freeze-drying machine, comprising a freeze-drying box 1 with liftable plates 1-6 inside, a condensation trap 3 connected to the freeze-drying box 1 through a septum valve 2, a compressor 10, and the freeze-drying box 1 and the air inlets 1-1 and 3-1 of the condensate catcher 3 are connected with a gas supply pipeline 4, and the freeze-drying box 1 and the cleaning ports 1-2 and 3-2 of the condensate catcher 3 are connected There is a cleaning pipeline 5, and the drain outlets 1-3 and 3-3 of the freeze-drying box 1 and the condensate catcher 3 are connected with a drain pipeline 6 through a discharge angle seat valve 6-1.

[0008] The above-mentioned freeze-drying box 1 is also connected with a silicon oil tank 7, and the silicon oil tank 7 is respectively provided with a refrigeration pipeline 11 for providing a cooling source for the silicone oil and a heater 8 for providing heat, and the oil outlet 7 of the silicon oil tank 7 -1 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com