Patents

Literature

40results about How to "Good freeze-drying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

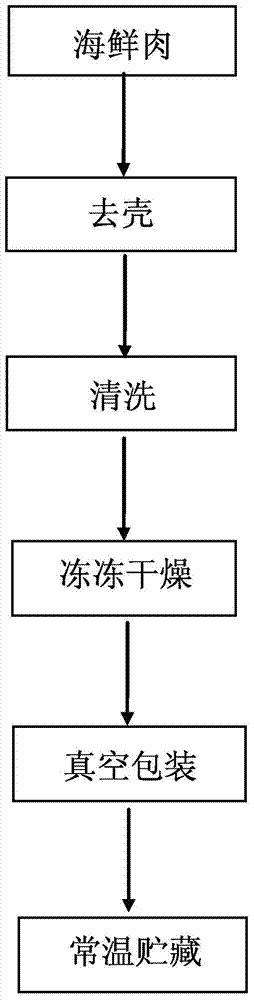

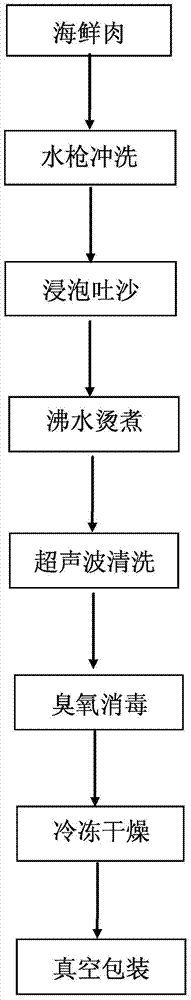

Manufacturing method for freeze-drying seafood

ActiveCN104770460AImprove hygieneEfficient killingMeat/fish preservationBivalves processingFood safetyFreeze-drying

The invention discloses a manufacturing method for freeze-drying seafood. The manufacturing method includes the following step of water gun flushing, sand splitting through soaking, boiling through boiling water, ultrasonic cleaning, ozone disinfecting, freeze drying and vacuum packaging. The manufacturing method has the advantages that dirt and impurities on the surface of seafood meat can be removed efficiently and comprehensively, microorganisms and parasites in the seafood meat are killed, a good fresh keeping effect is obtained through the complete freeze drying process, and the freeze-drying seafood meat conforming to the food safety national standard is obtained. The manufacturing method is suitable for freeze-drying manufacturing of seafood of a shellfish kind such as oysters, green sea snails, whelks, pearl sea snails, oyster drills, marine clams, abalones and dried scallop, a sleeve fish kind, a sea fish kind, a shrimp kind and the like.

Owner:北海市银海区蓝海牧场贝类养殖农民专业合作社

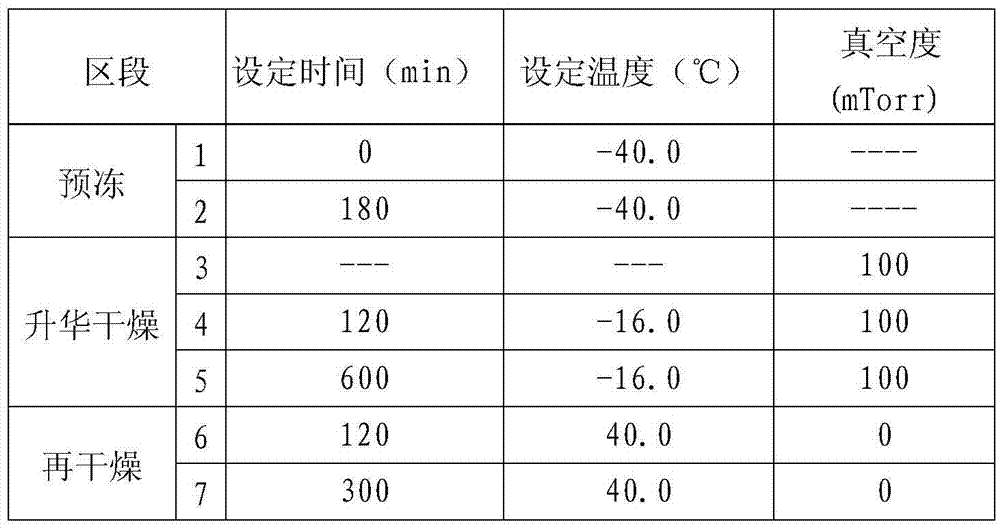

Processing method for vacuum freeze-drying fruit and vegetable yoghourt

InactiveCN106035660AImprove immunityPrevent proliferationMilk preparationMilk preservationNutritive valuesFreeze-drying

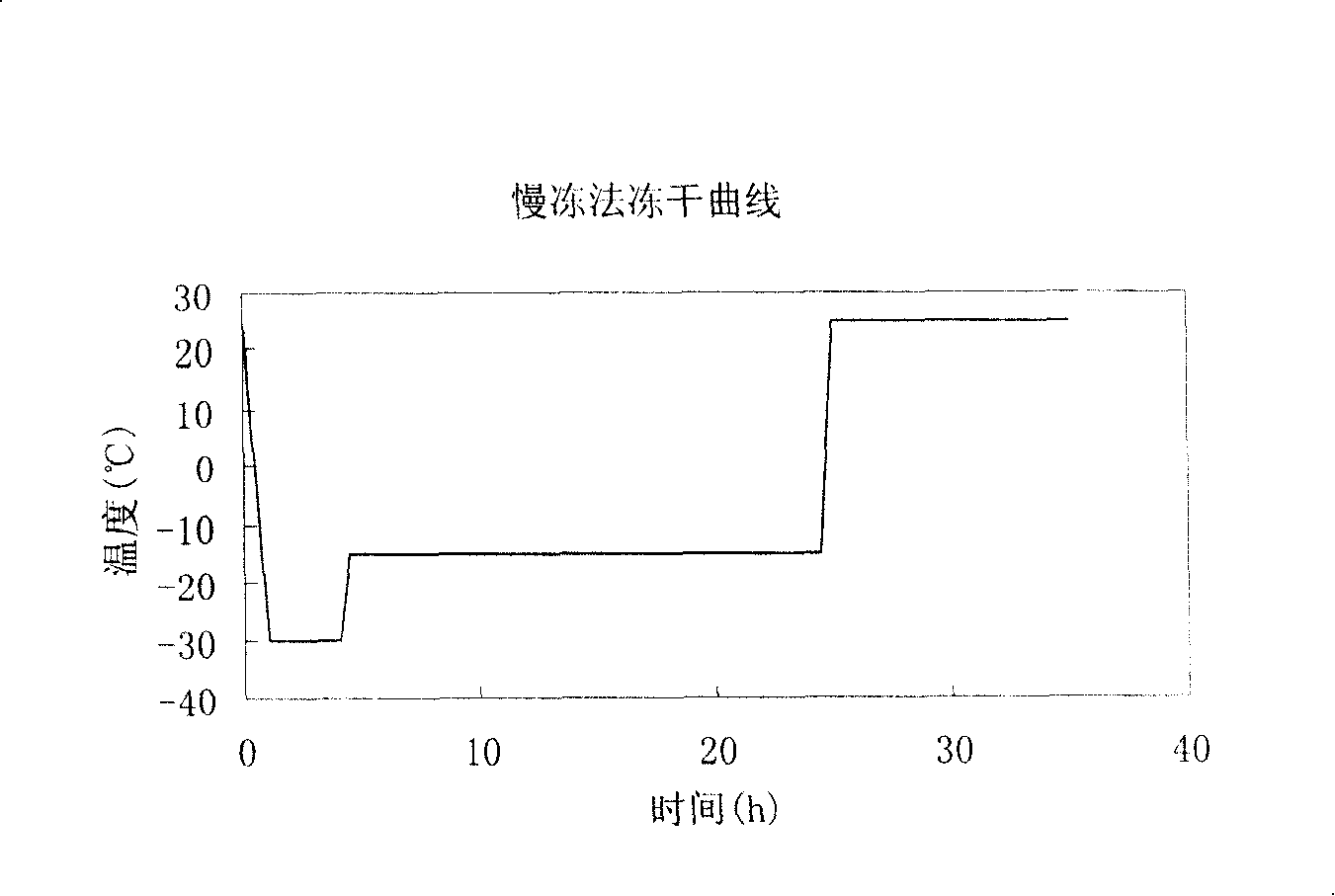

The invention discloses a processing method for a vacuum freeze-drying fruit and vegetable yoghourt. The processing method comprises the following steps: a) mixing of raw materials; b) homogenizing; c) sterilizing; d) freezing; e) stirring and puffing; f) forming; g) putting on a tray and quickly freezing; h) panning and quickly freezing: taking out product grains after being quickly frozen and shaped from the material tray and putting into an aluminum plate, and putting into a freezing chamber at -32 to -28 DEG C for secondarily quick freezing for 3-4 hours till the central temperature of the products reach at -35 to -28 DEG C; i) vacuum freeze-drying; j) sorting; k) metal detecting; and l) packaging. The processing method for the vacuum freeze-drying fruit and vegetable yoghourt has the advantages that the palatability is excellent and the nutritive value is ultrahigh; the edible taste of the fruit and vegetable yoghourt is greatly promoted; and a freeze-drying curve is obtained by repeated tests and is a customized freeze-drying process route special for the characteristics of the fruit and vegetable yoghourt, so that the fruit and vegetable yoghourt can achieve an optimal freeze-drying effect.

Owner:HUBEI XINMEIXIANG FOODS

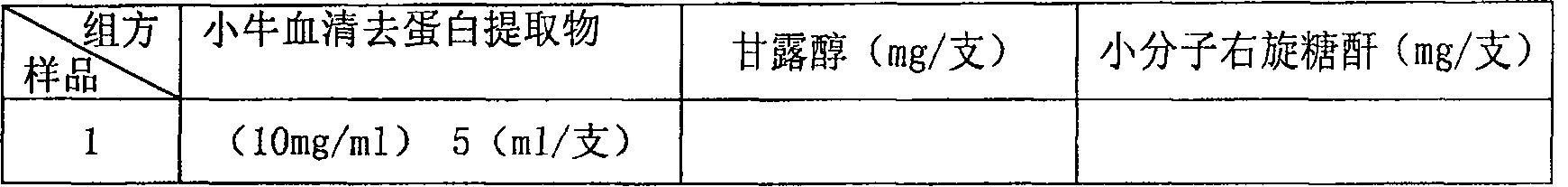

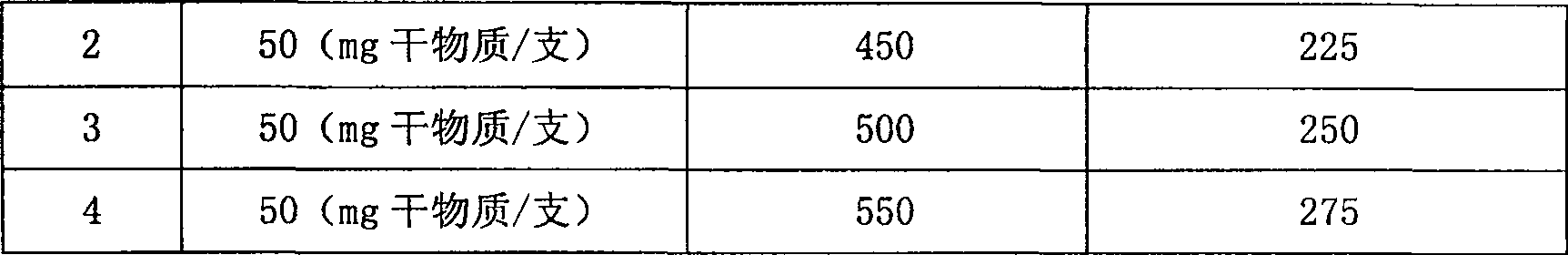

Calf serum protein-removing extract for injection and its preparation method

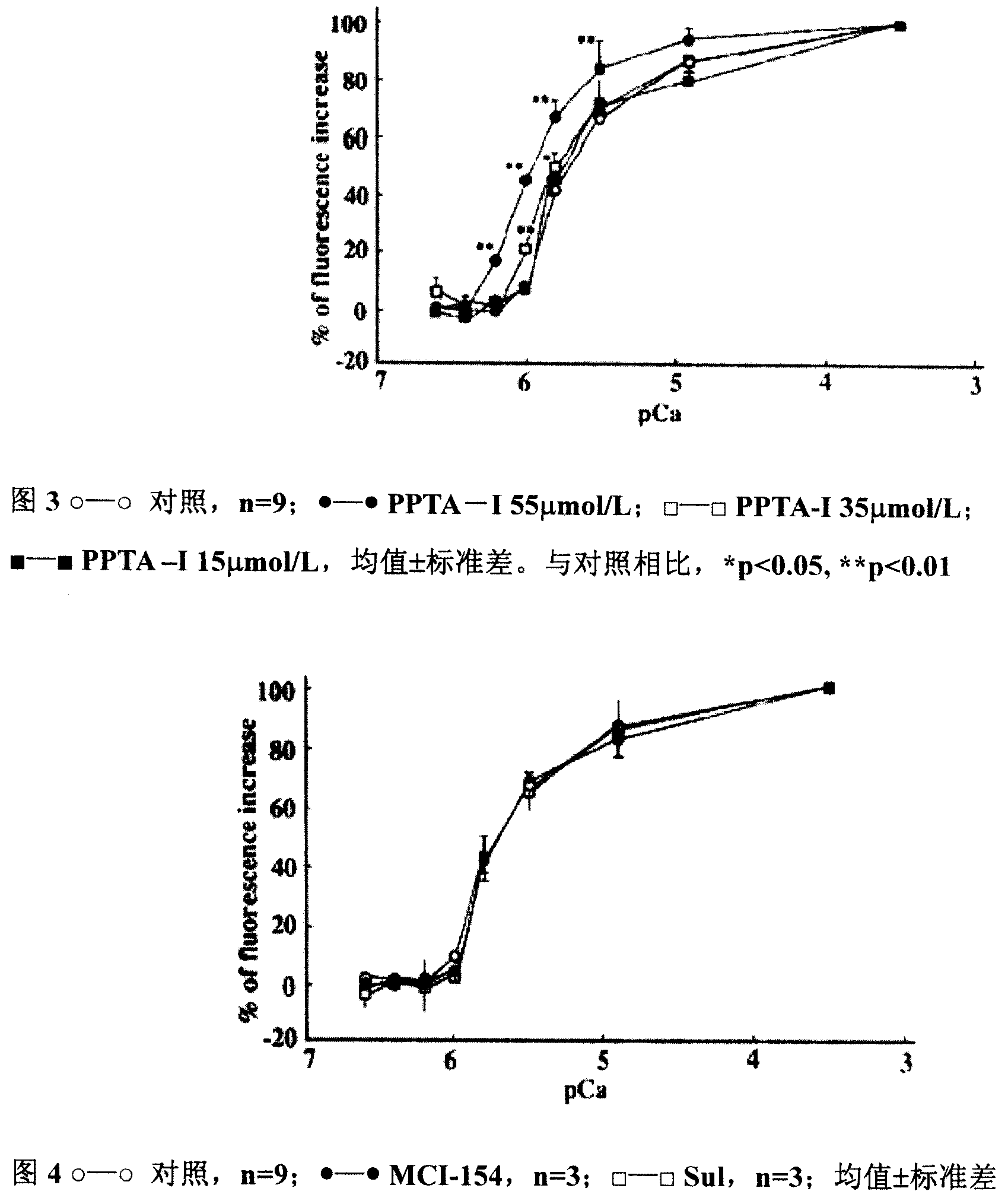

ActiveCN100531723CDelicate appearanceImprove product qualityPowder deliveryMammal material medical ingredientsMannitolDextran

The invention discloses a calf serum deproteinized extract freeze-dried powder injection and a preparation method thereof. The calf serum deproteinized extract freeze-dried powder injection contains the following components by weight and ratio: 1 part of dry matter of calf serum deproteinized extract; 9-11 parts of mannitol; and 4.5 parts of small molecule dextran -5.5 parts. The deproteinized calf serum extract freeze-dried powder injection of the present invention overcomes the defects of unstable water injection and infusion quality, prolongs the valid period of the product, expands clinical application, and reduces the probability of adverse reactions.

Owner:JINZHOU AHON PHARM CO LTD

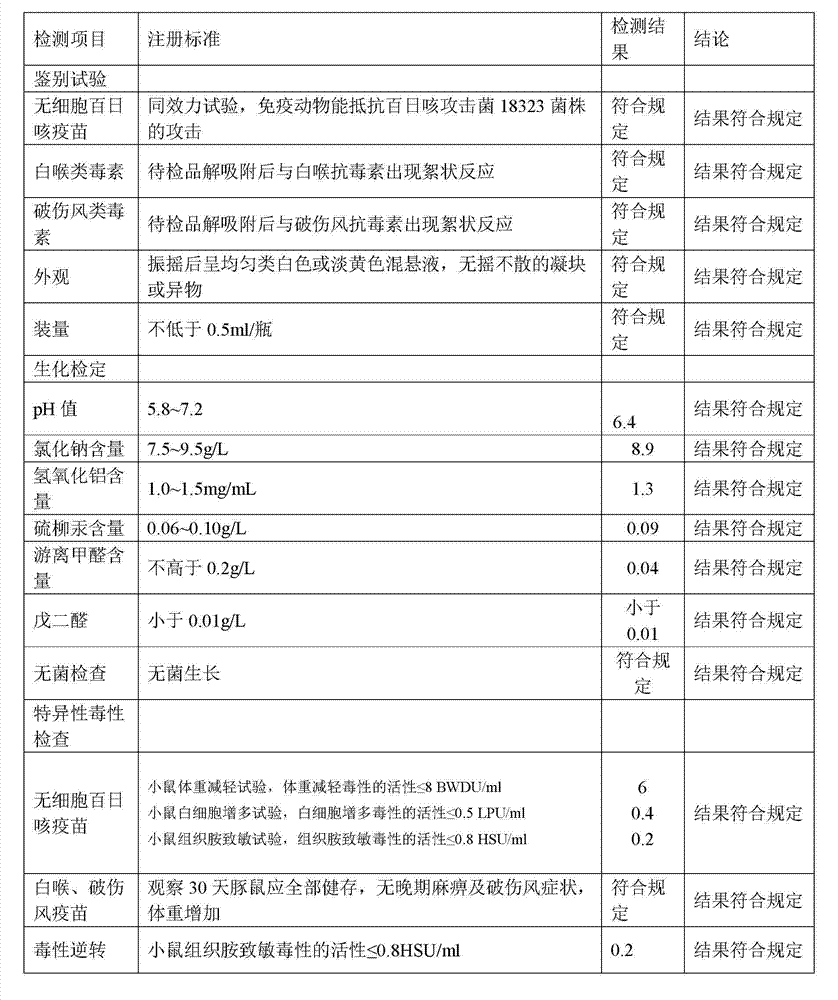

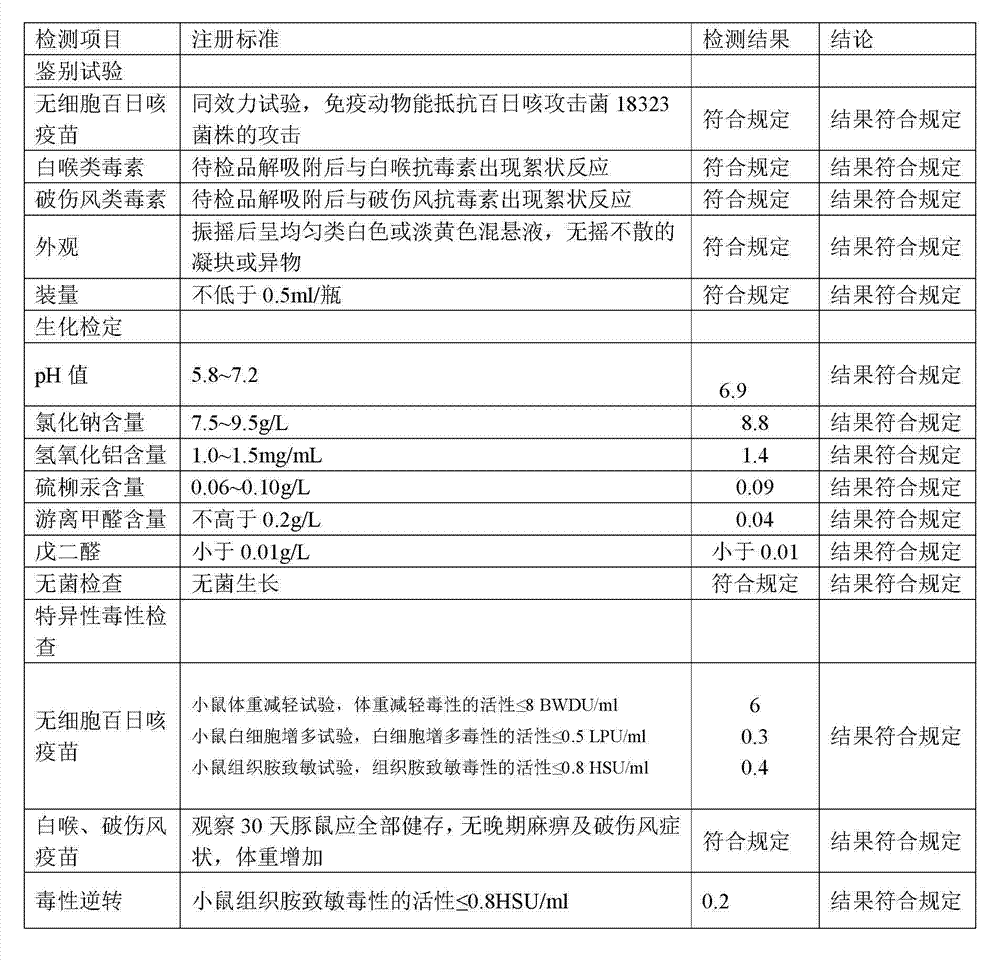

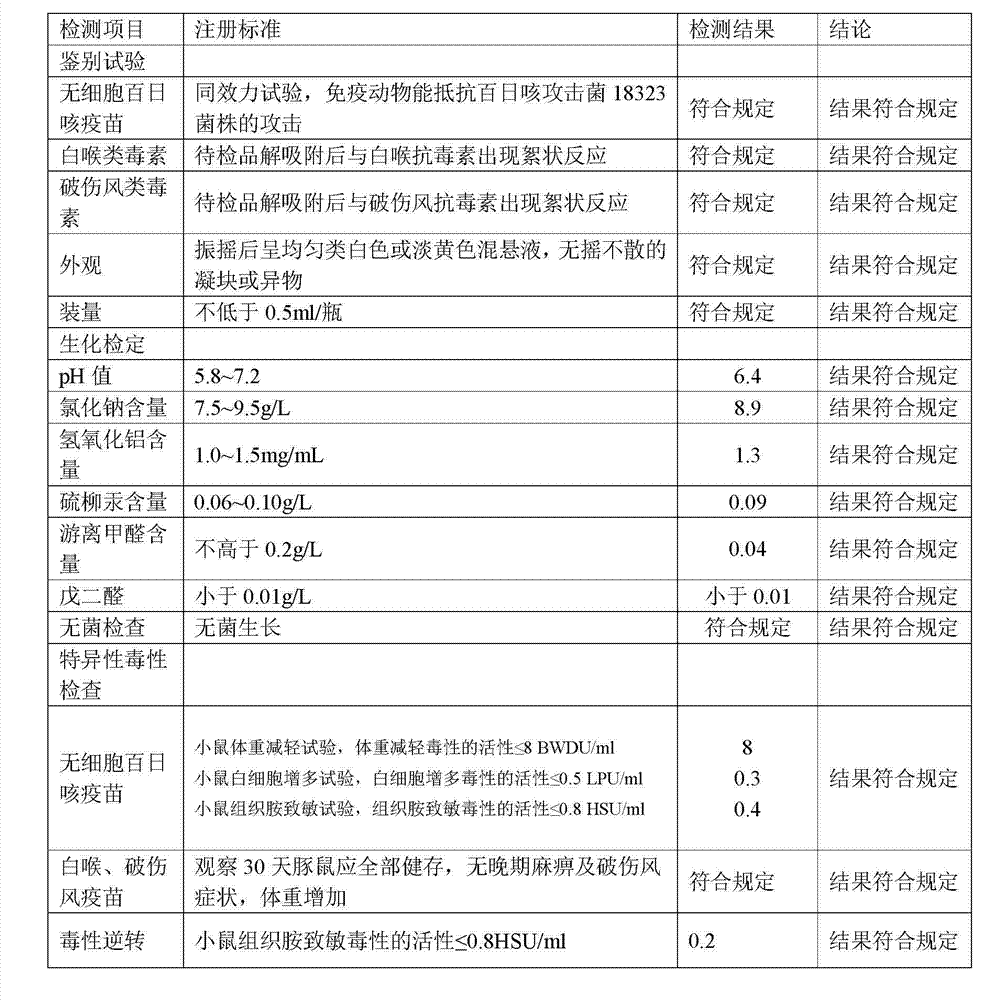

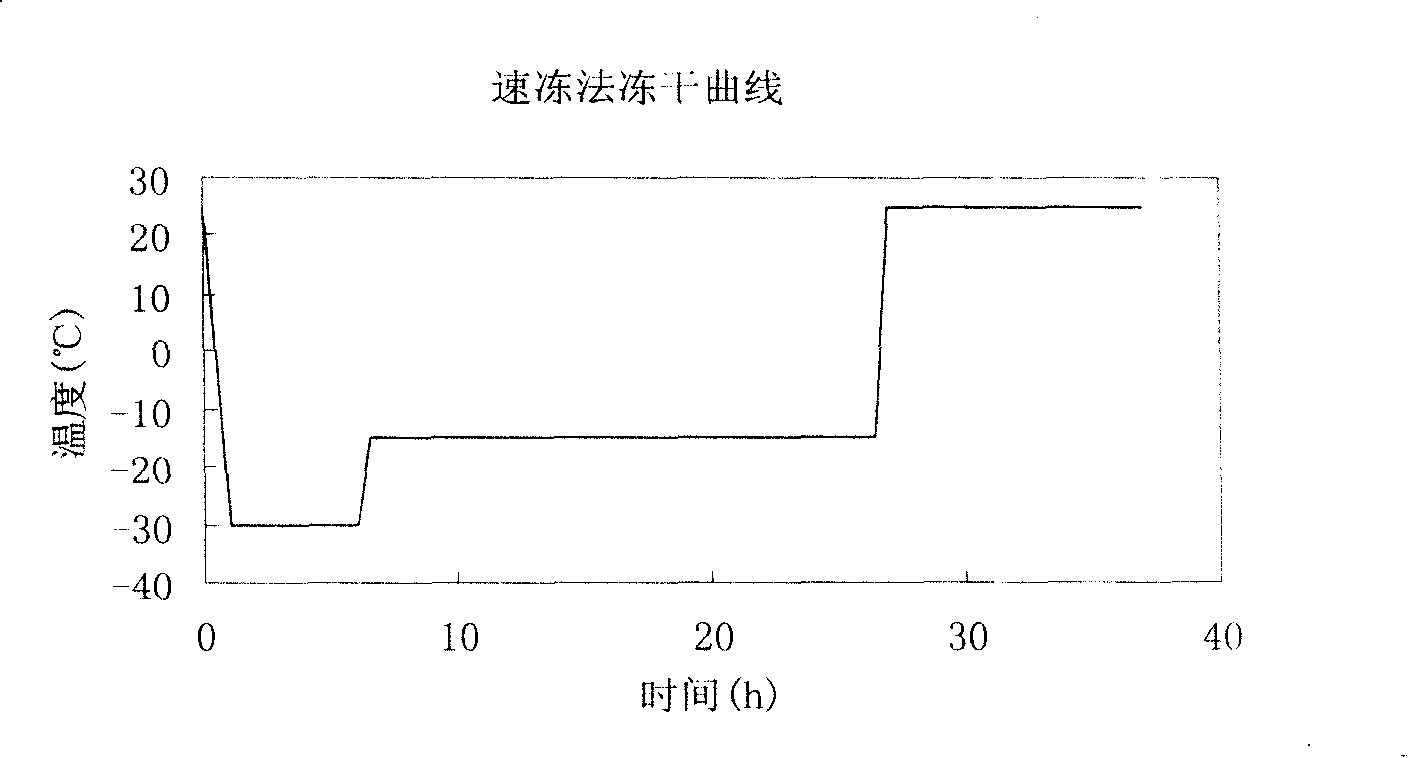

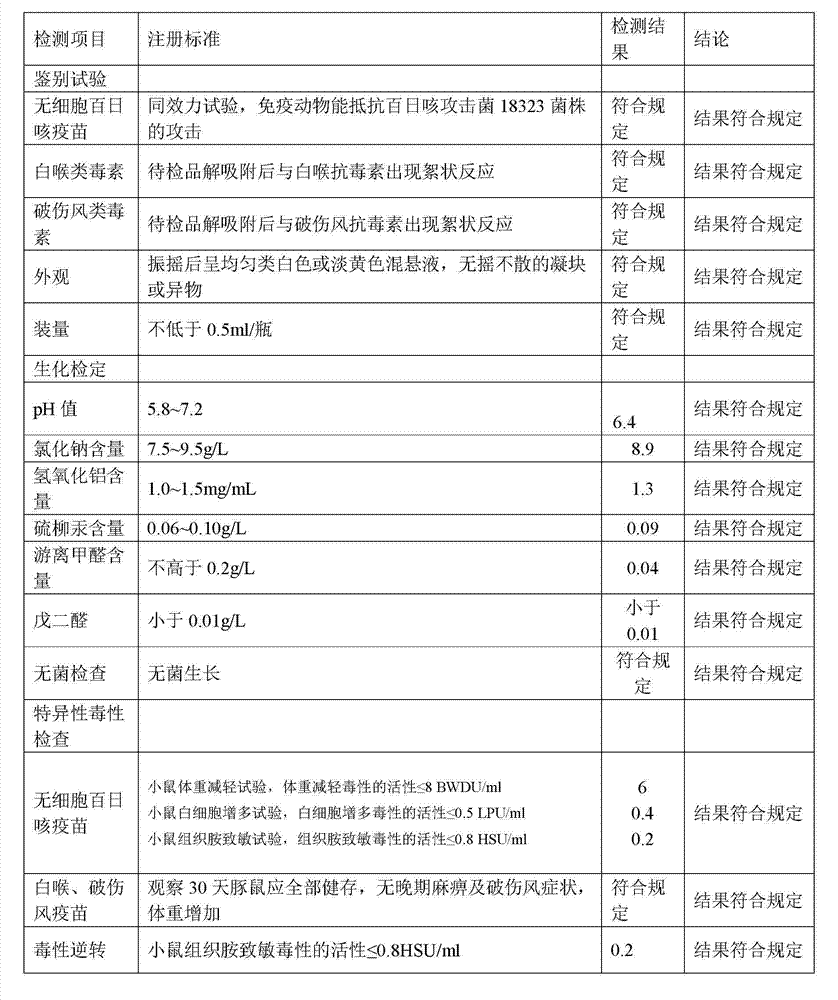

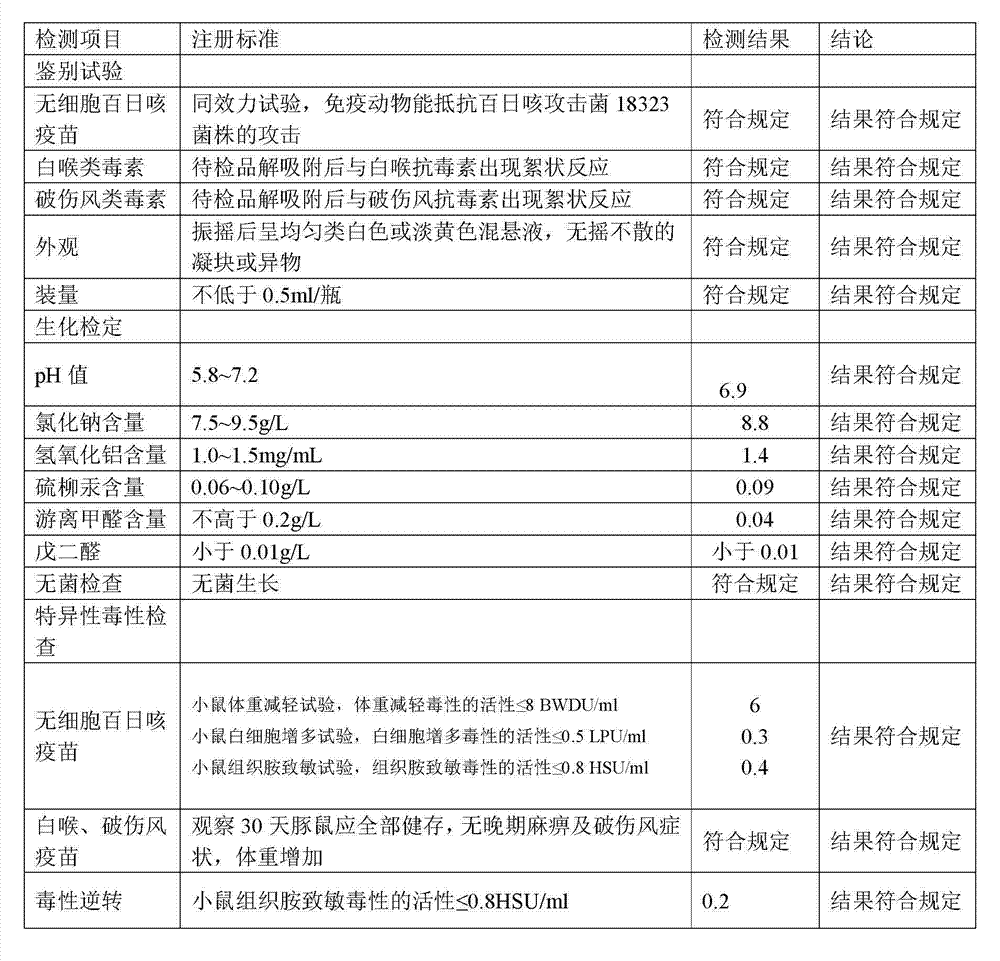

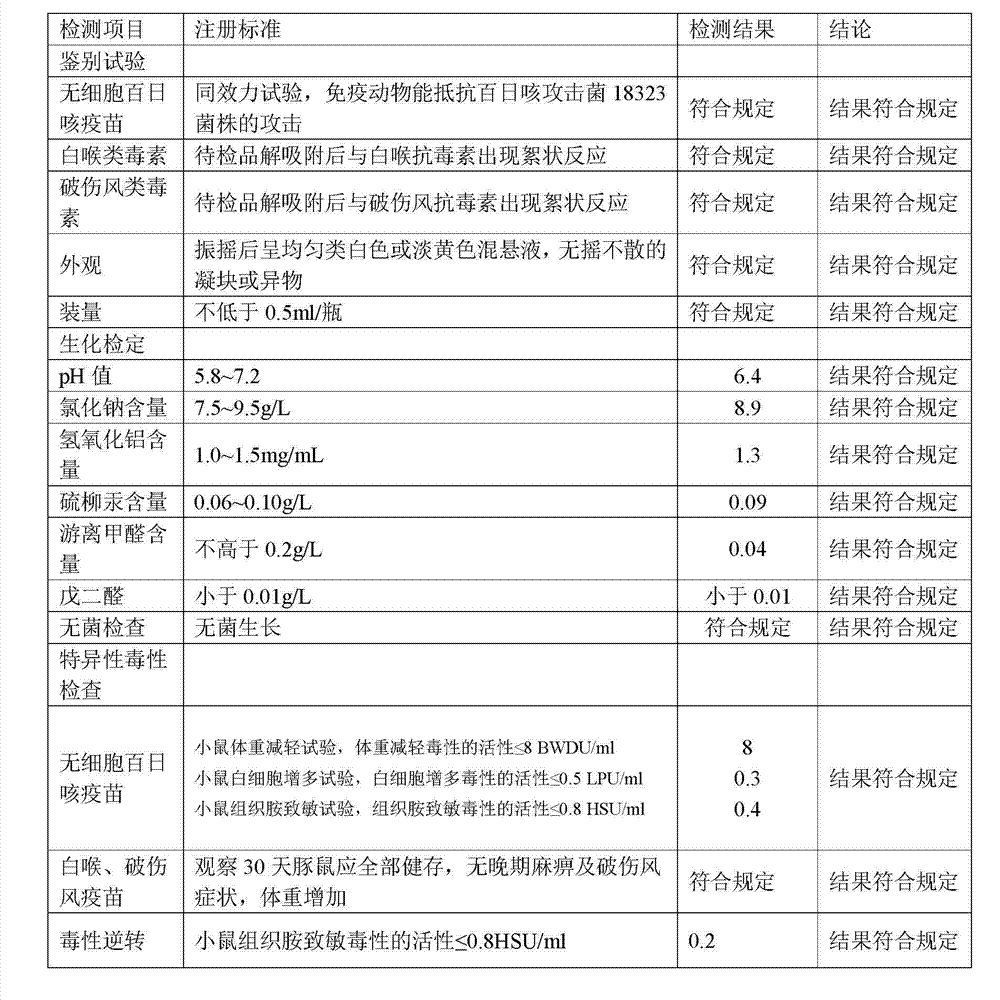

Diphtheria, tetanus and acellular pertussis/Haemophilus influenzae type b - group A and C meningococcus combined vaccine

ActiveCN102813917AGood freeze-drying effectRelieve painAntibacterial agentsBacterial antigen ingredientsDiseaseTetanus

The invention provides a diphtheria, tetanus and acellular pertussis / Haemophilus influenzae type b - group A and C meningococcus combined vaccine, which has the characteristics of high safety, high efficacy, high controllability and prevention of multiple diseases through one injection, satisfies relevant requirements on absorbed diphtheria, tetanus and acellular pertussis combined vaccines, Haemophilus influenzae type b combined vaccines and group A and C meningococcus combined vaccines in the Third Part of Chinese Pharmacopoeia (2010) and proposed Rules on Production and Inspection of Diphtheria, Tetanus and acellular Pertussis / Haemophilus influenzae Type b - Group A and C Meningococcus Combined Vaccines, and achieves an effect of putting into practical application.

Owner:WUHAN INST OF BIOLOGICAL PROD CO LTD

Peperphentonamine hydrochloride freeze-dried injection and preparation and application thereof

ActiveCN101234102AWell formedGood freeze-drying effectPowder deliveryPharmaceutical non-active ingredientsSolubilityFreeze-drying

The invention relates to pepperphentonamine chloride jelly powder injection and a preparation method thereof; the preparation comprises 1 portion of pepperphentonamine chloride, 2.5-3.0 portions of excipient and 400-600 portions of water for injection with PH value of 1.5-5.5; the preparation is prepared through freezing drying. The excipient is mannitol, dextran, lactose, sugar, polyglycol, poloxamer and glycin, etc.; 1 portion of the pepperphentonamine chloride, 10 portions of the mannitol and 500 portions of the water for injection with PH value of 2.0-3.0 are preferably chosen. The pepperphentonamine chloride and the excipient are added into the water for injection to be heated (40-90 DEG C), ultrasonic oscillated, degermed, subpackaged, pre-frozen, multi-stage dried and packed to obtain the products. A brown glass bottle is preferably chosen for subpackage. The pepperphentonamine chloride preparation of the invention has excellent appearance, color and solubility, good stability and long preservation period. The invention also relates to application of the preparation used for preparing therapeutic drugs for heart failure and / or myocardial protection.

Owner:江西国能医药科技有限公司

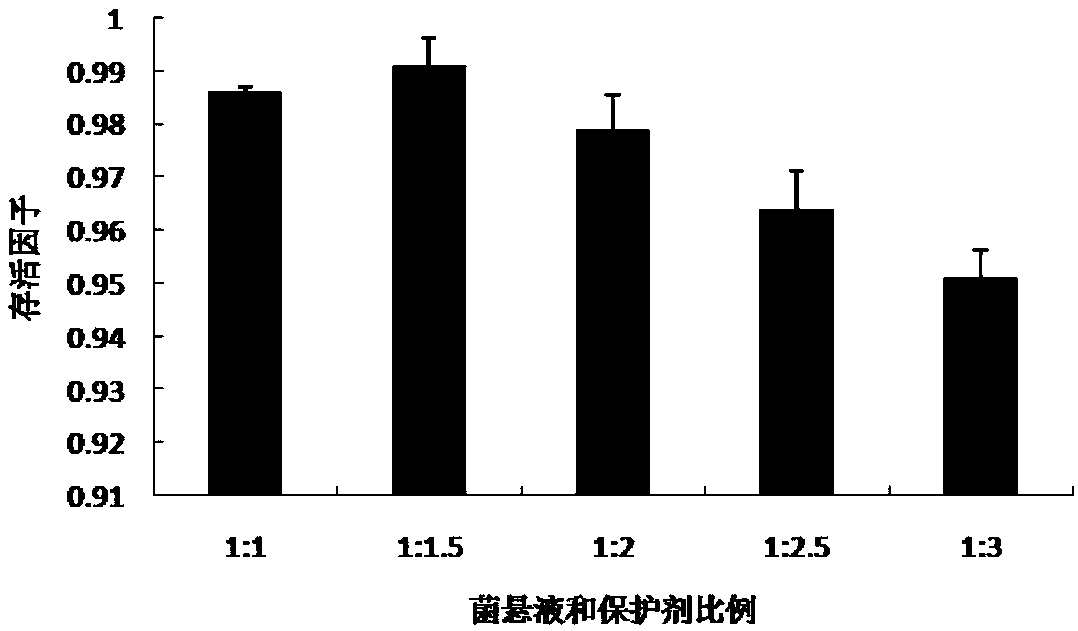

Preparation method of freeze-dried lactobacillus paracasei powder

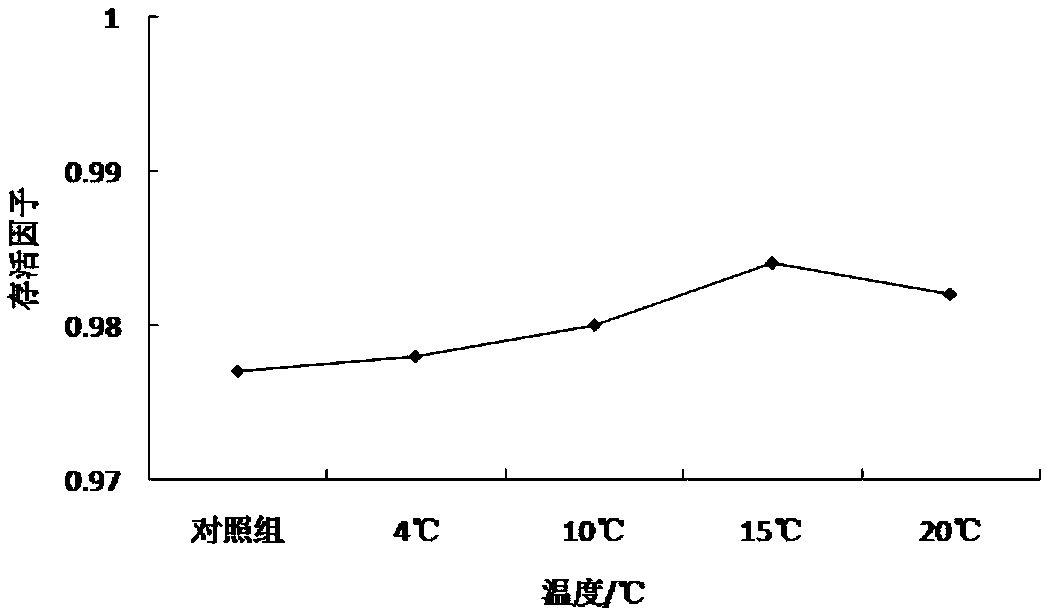

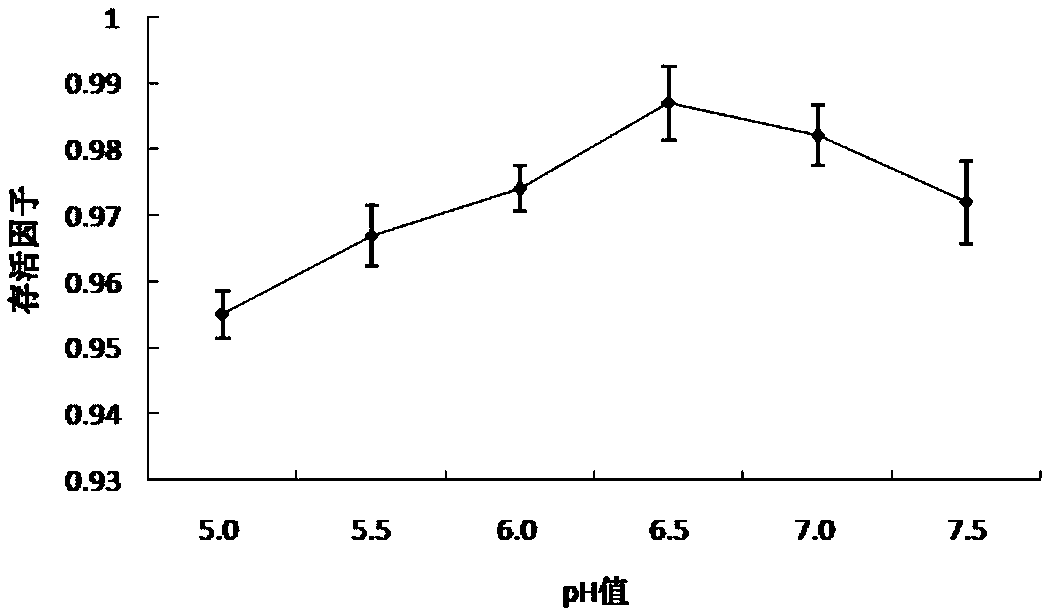

ActiveCN111286469AImprove protectionIncrease resistanceBacteriaMicroorganism based processesBiotechnologySucrose

The invention discloses a preparation method of freeze-dried lactobacillus paracasei powder, and belongs to the technical field of probiotic starter culture. The method comprises the following steps:collecting thalli of lactobacillus paracasei, and then mixing the thalli with a freeze-drying protective additive, wherein the freeze-drying protective additive is prepared from skim milk powder, canesugar, polyvinylpyrrolidone, glutathione and water; then paving a mixed solution of thalli and the freeze-drying protective additive in a freeze-drying vessel for pre-freezing treatment, and after the mixture of the thalli and the freeze-drying protective additive are completely frozen, carrying out vacuum freeze-drying treatment on a pre-frozen sample. The survival factor of thalli in the freeze-dried lactobacillus paracasei powder prepared by the preparation method disclosed by the invention reaches 0.998 + / -0.001, the viable count is 2.35 * 10 < 11 > cfu / g, and the viable count content ishigh. And necessary technical support is provided for development of lactobacillus paracasei products and the aspects of dairy products, foods, medicines and the like.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method for preparing injection reduced glutathione freeze-dried powder

InactiveCN102670523AImprove stabilityGood freeze-drying effectPowder deliveryMetabolism disorderDiseaseDiabetes mellitus

The invention provides a method for preparing injection reduced glutathione freeze-dried powder widely used for auxiliary treatment of multi-system or multi-organ diseases such as liver or kidney injury and diabetes. According to the method, reduced glutathione is used as an active ingredient and added with a pH regulator and injection water, and the injection reduced glutathione freeze-dried powder is prepared by freeze-drying. For overcoming the defects of the conventional technology for preparing the injection reduced glutathione freeze-dried powder, the invention provides the method for preparing the injection reduced glutathione freeze-dried powder. The reduced glutathione freeze-dried powder is prepared by strictly controlling formulation selection, solution preparation and freeze-drying processes; and although the method is long in freeze-drying time, the reduced glutathione freeze-dried powder prepared by the method is high in stability and has a good freeze-dried effect.

Owner:双鹤药业(海南)有限责任公司

Cherry freeze-drying process

InactiveCN105746694AGuaranteed uniformityNutritional value is not lostFruits/vegetable preservation by freezing/coolingFood treatmentSurface moistureFreeze-drying

The invention relates to a cherry freeze-drying process. The process comprises the following steps: picking cherries with the ripeness of 80-90 percent, removing fruit stems of the cherries, and placing the cherries in the shade; removing rotten fruits and special-shaped fruits, cleaning the residual cherries under constant temperature conditions, draining off the surface moisture, and performing kernel removal treatment; adding the cherries in normal temperature fresh-keeping liquor, taking out the cherries from the fresh-keeping liquor, and draining off the surface liquid; filling the cherries into a preservative bag and sealing, and placing the bag in a refrigerated cabinet; sequentially stacking the cherries on a tray, wherein the stacking thickness of the cherries on the tray is 1-2 layers; putting the cherries stacked on the tray in a subzero storage or on a radiant panel with a refrigeration function for performing quick-freezing treatment to the center, and putting the cherries into a freeze-drying warehouse; and starting a heating circulating pump, and controlling the temperature of the radiant panel, so that the temperature of the cherries gradually returns to 20-30 DEG C; and stopping equipment operation, opening the freeze-drying warehouse door, taking out the cherries and warehousing. The process disclosed by the invention has the characteristics of good preservation effect, long time, capacity of performing uniform freeze-drying, good freeze-drying effect and the like.

Owner:JIANGSU BOLAIKE FROZEN TECH DEV CO LTD

Vacuum freeze-dried fermented milk blocks and preparation method thereof

The invention discloses vacuum freeze-dried fermented milk blocks and a preparation method thereof. The fermented milk blocks comprise the following raw materials in percentage by weight of 12-15% ofa fruit and vegetable dice / cereal / nut dice composition, 6-7% of nonfat dry milk powder, 1-1.5% of whey powder, 3-5% of malt syrup, 5-7% of white granulated sugar, 3-5% of maltodextrin, 0.02-0.05% of pectin, 0.4-0.5% of corn starch and the balance of fermented milk. The vacuum freeze-dried fermented milk blocks have various product shapes.

Owner:福建立兴食品股份有限公司

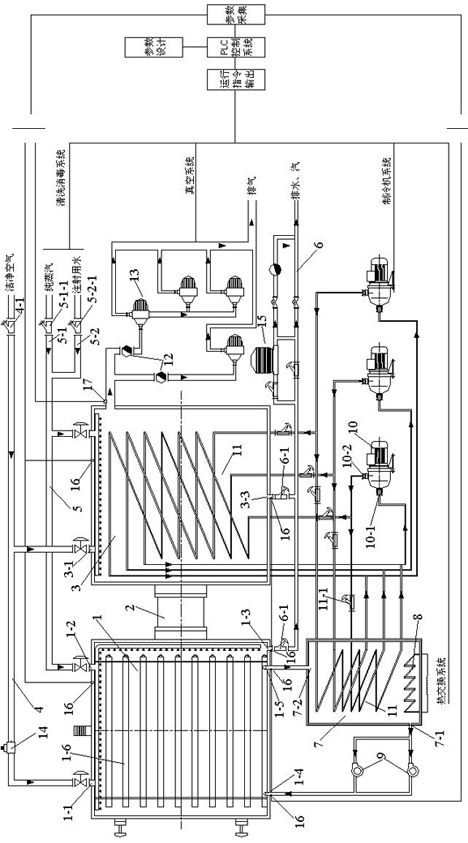

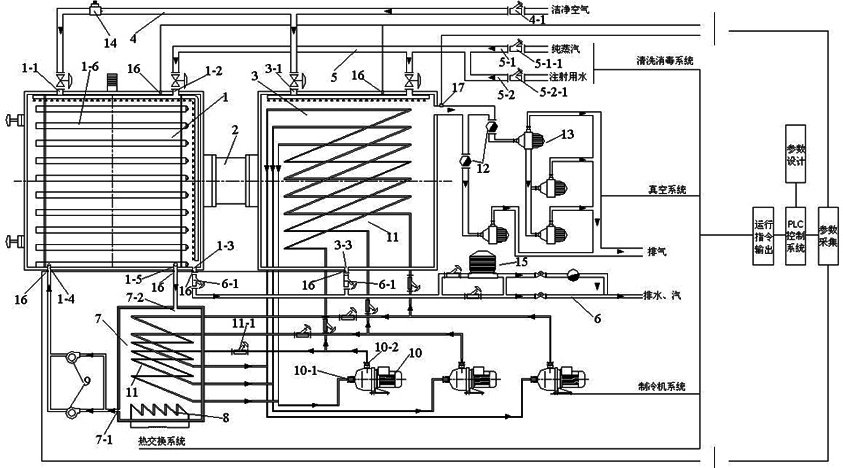

Lyophilizer

InactiveCN101986071AImprove integrityGood freeze drying effectDrying solid materials without heatFreeze-dryingEngineering

The invention relates to a lyophilizer, comprising a lyophilisation box with lifting board layers inside, a condensing water catcher connected with the lyophilisation box by a middle separating valve and a compressor. The lyophilizer is characterized in that air inlets of the lyophilisation box and the condensing water catcher are connected with an air supply pipe; washing openings of the lyophilisation box and the condensing water catcher are connected with a washing pipe; and discharge outlets of the lyophilisation box and the condensing water catcher are connected with a discharge pipe by discharge angle seat valves. The lyophilizer has good integrity and good lyophilisation effect and is convenient to control in the production process.

Owner:兆丰华生物科技(福州)有限公司

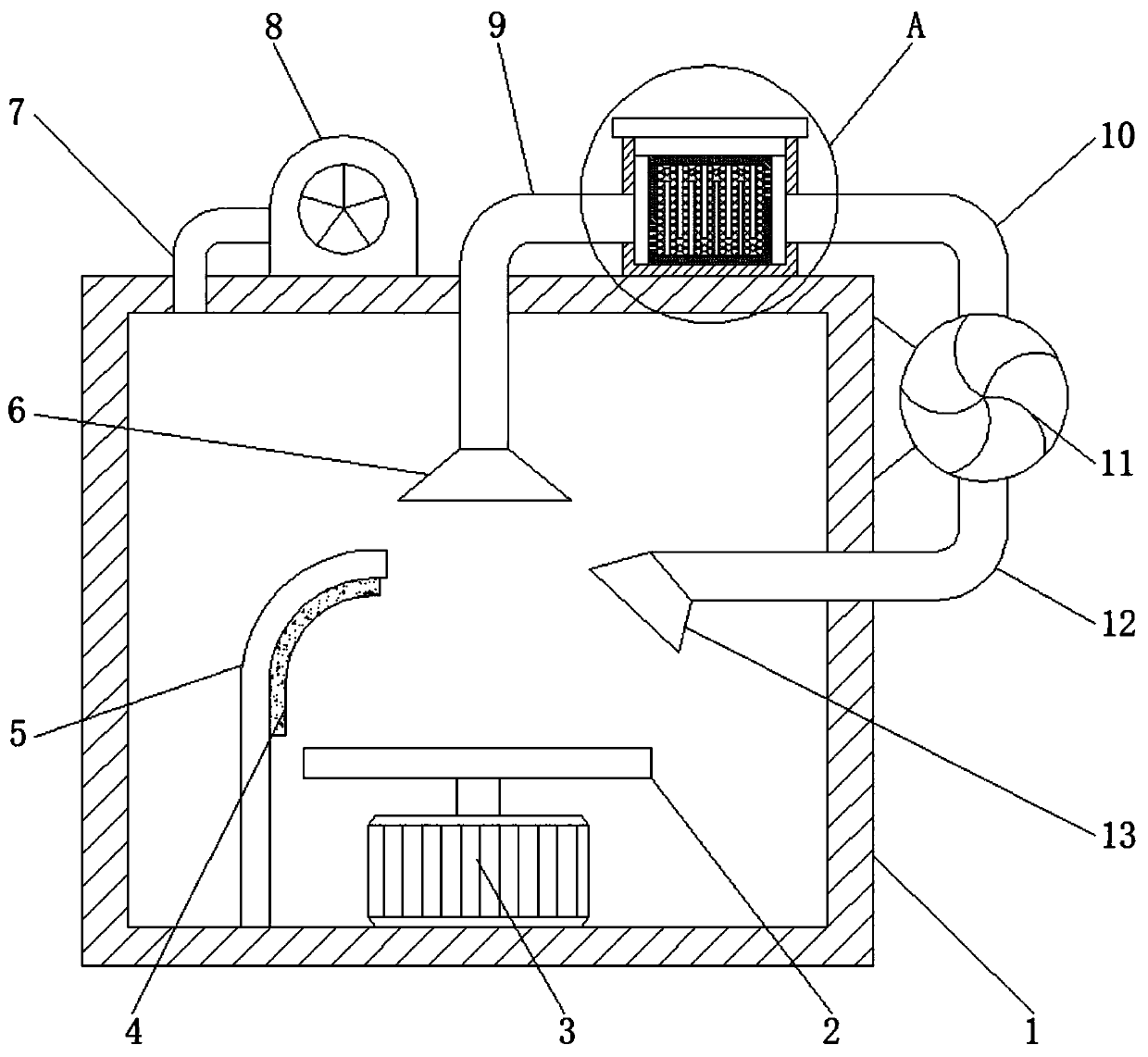

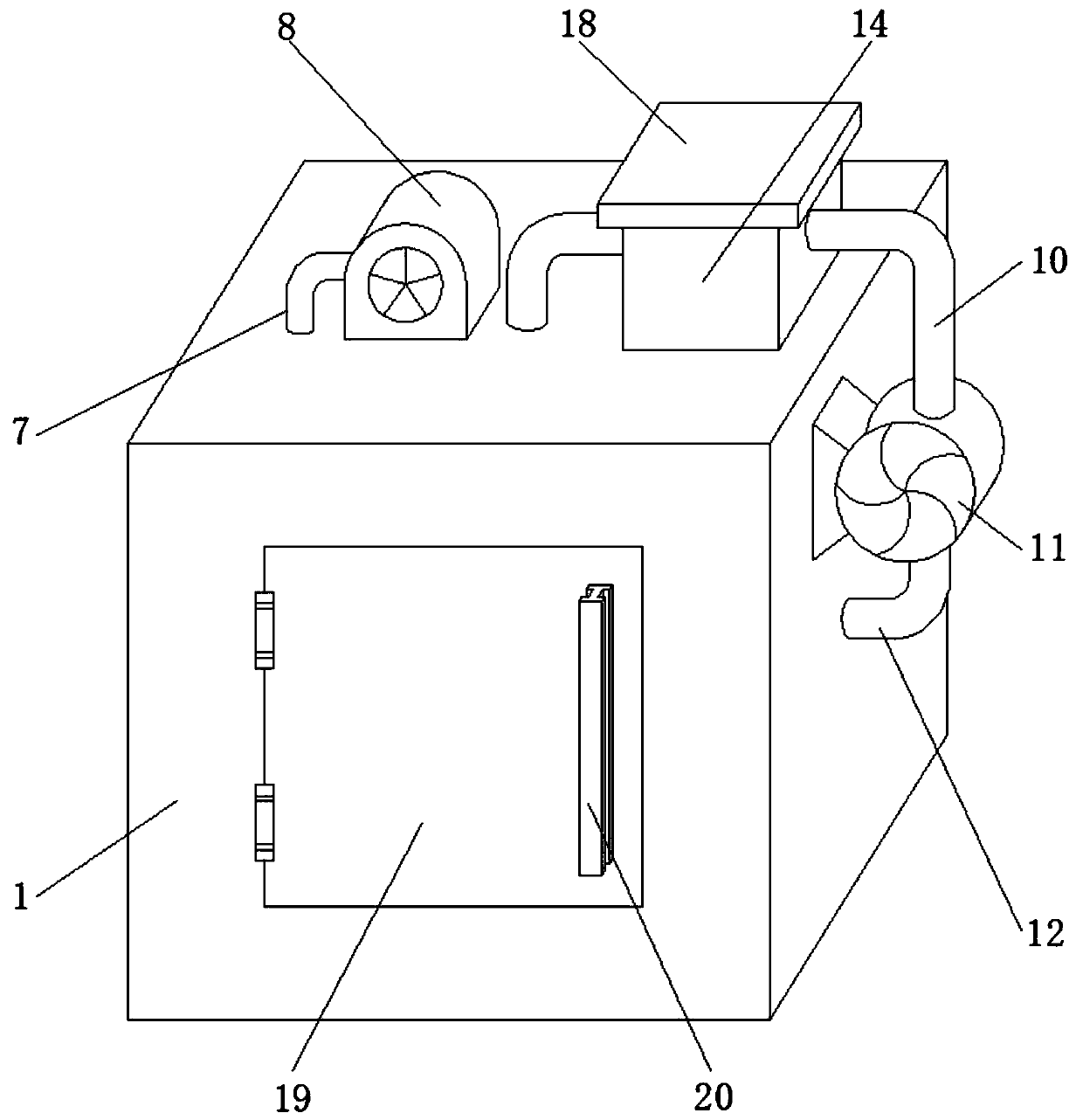

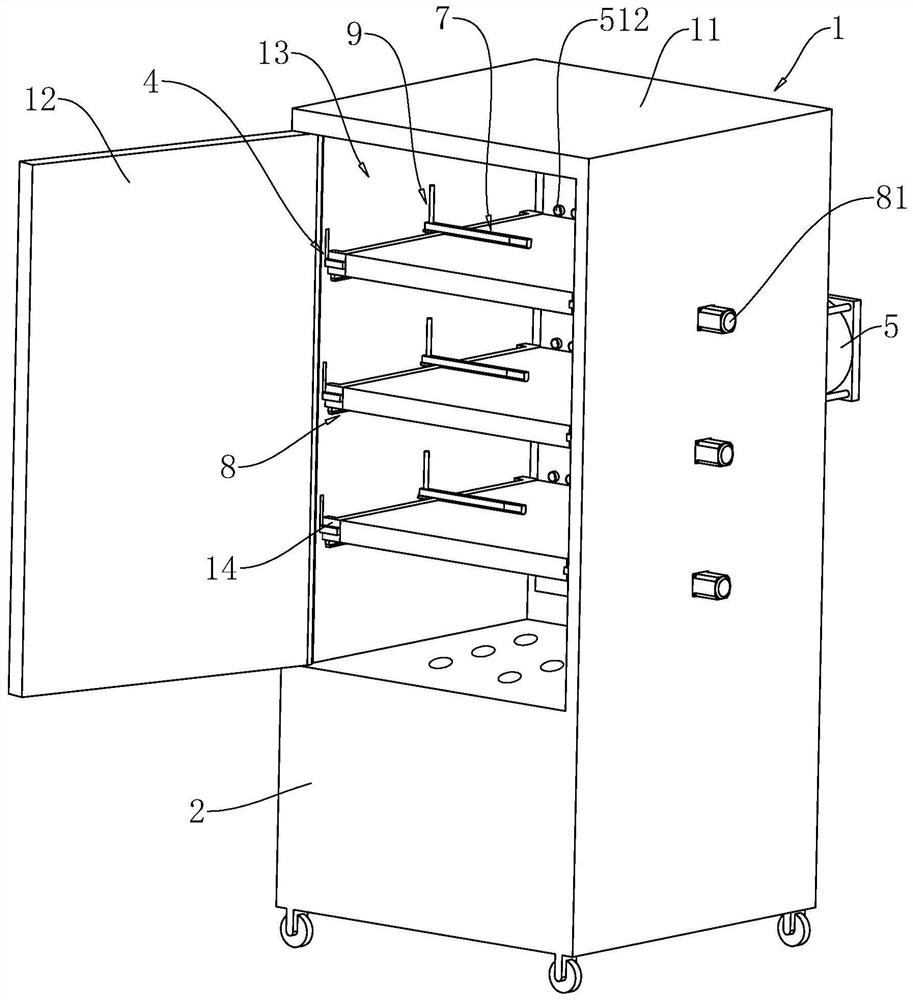

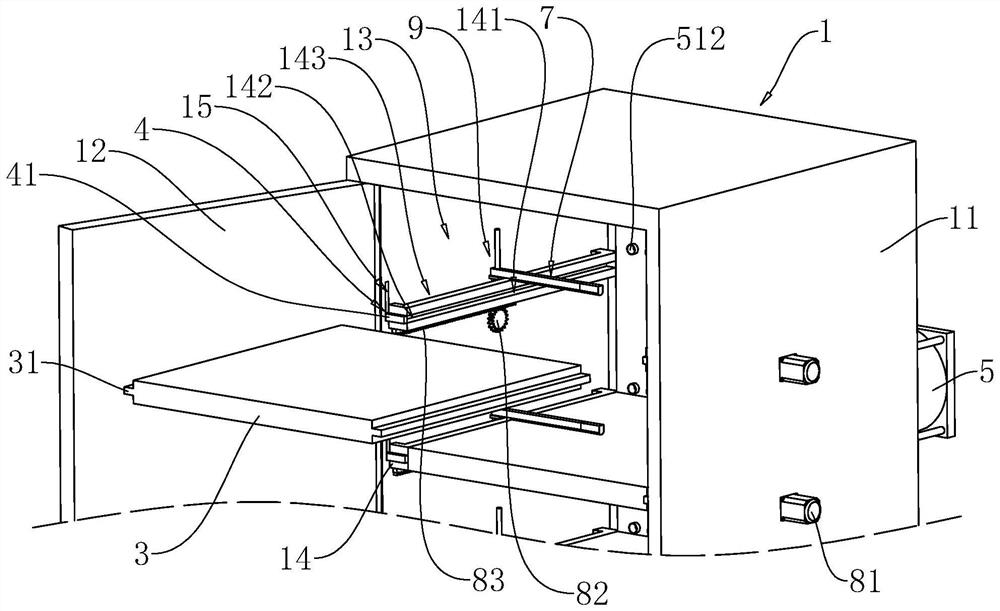

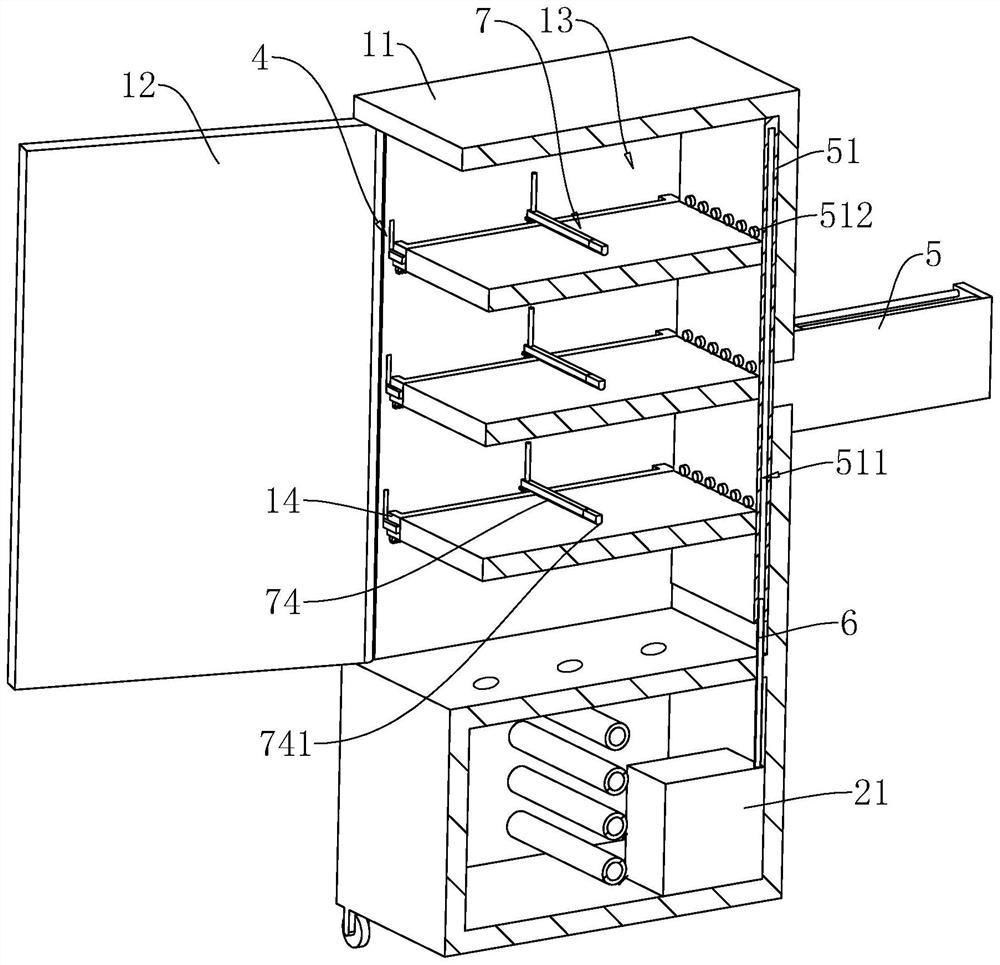

Freeze-drying equipment for food processing

InactiveCN110836571AHeating evenlyIncrease water evaporation rateDrying solid materials without heatDrying chambers/containersHeat AvoidanceProcess engineering

The invention discloses a freeze-drying equipment for food processing. The freeze-drying equipment comprises a freeze-drying box, the inner wall of the bottom part of the freeze-drying box is connected with a motor through bolts, one end of an output shaft of the motor is provided with a rotary table, the outer wall of the top part of the freeze-drying box is provided with a fixing frame, the outer wall of one side of the fixing frame is provided with a heating plate, the outer wall of the top part of the freeze-drying box is connected with a vacuum pump through the bolts, the outer wall of one side of the vacuum pump is provided with an air extraction pipe, one end of the air extraction pipe communicates with the freeze-drying box, the outer wall of one side of the freeze-drying box is provided with a fixing port, and the inner wall of the fixing port is rotationally connected with a box door through a hinge. According to the freeze-drying equipment for food processing, the uniform heating of food is realized, the evaporation rate of moisture in foods is effectively accelerated, the use effect is better, the heat energy loss is avoided while the moisture is absorbed, the requirements of energy conservation and environmental protection are met, meanwhile, a water absorption resin which is located between baffle plates fully absorbs the moisture, the dehydration effect is better, and the freeze-drying effect of the equipment is further improved.

Owner:耒阳市刘燕酿制生物科技有限公司

Freeze-drying protective agent for prolonging normal-temperature preservation of probiotics and freeze-drying method

InactiveCN113234596AGood freeze-drying effectExtended service lifeMicroorganism preservationBiotechnologyActive agent

The invention discloses a freeze-drying protective agent for prolonging normal-temperature preservation of probiotics and a freeze-drying method, and belongs to the technical field of probiotic production. The freeze-drying protective agent is prepared from, by weight, 17-21 parts of trehalose, 1-3 parts of saccharifying enzyme, 5-12 parts of linolenic acid, 10-11 parts of mannitol, 6-9 parts of serum albumin, 0.01-0.02 part of surfactant, 0.01-0.03 part of defoaming agent, 1-3 parts of sodium chloride, 2-5 parts of sodium citrate and 10-15 parts of lentinan. By adding linolenic acid, sodium chloride and sodium citrate, the freeze-drying effect of trehalose and mannitol at normal temperature can be effectively prolonged, the freeze-drying effect of the freeze-drying protective agent is enhanced, the service life of the freeze-drying protective agent is prolonged, and the freeze-drying protective agent is simple in process, low in cost and convenient to popularize and use.

Owner:安徽善和生物科技有限公司

Freeze-dried composition of mycophenolate mofetil and preparation method thereof

ActiveCN106913531AGood resolubilityReduce manufacturing costOrganic active ingredientsPowder deliveryFreeze dryActive component

The invention provides a freeze-dried composition of mycophenolate mofetil. The freeze-dried composition of mycophenolate mofetil is mainly composed of the active component mycophenolate mofetil, a stabilizing agent, a cosolvent, a pH regulating agent and injection water. The freeze-dried composition of mycophenolate mofetil is in the shape of a loose block, can be rapidly dissolved after addition of water, has good dissolvability and is free of shrinkage after long-term preservation; and freeze-drying time is short, so production cost is greatly reduced.

Owner:SHANDONG NEWTIME PHARMA

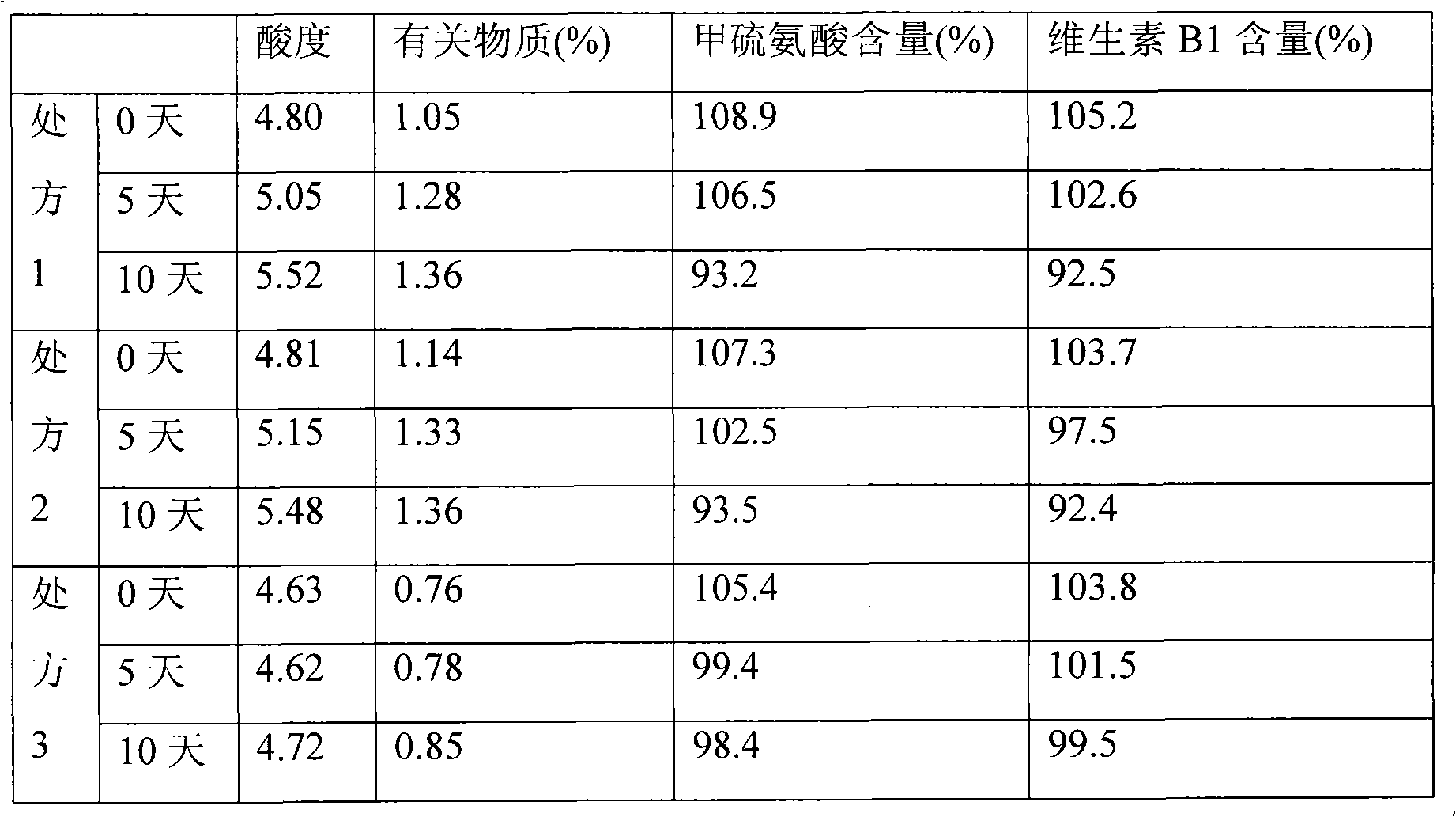

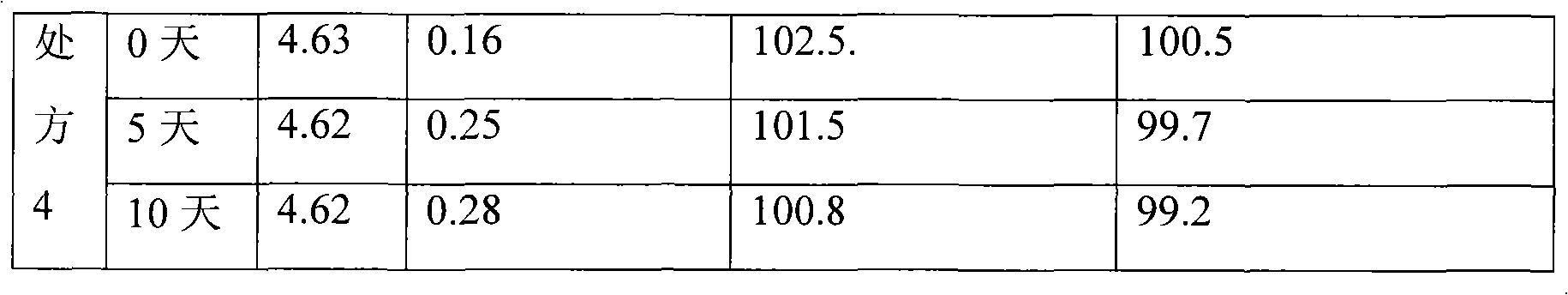

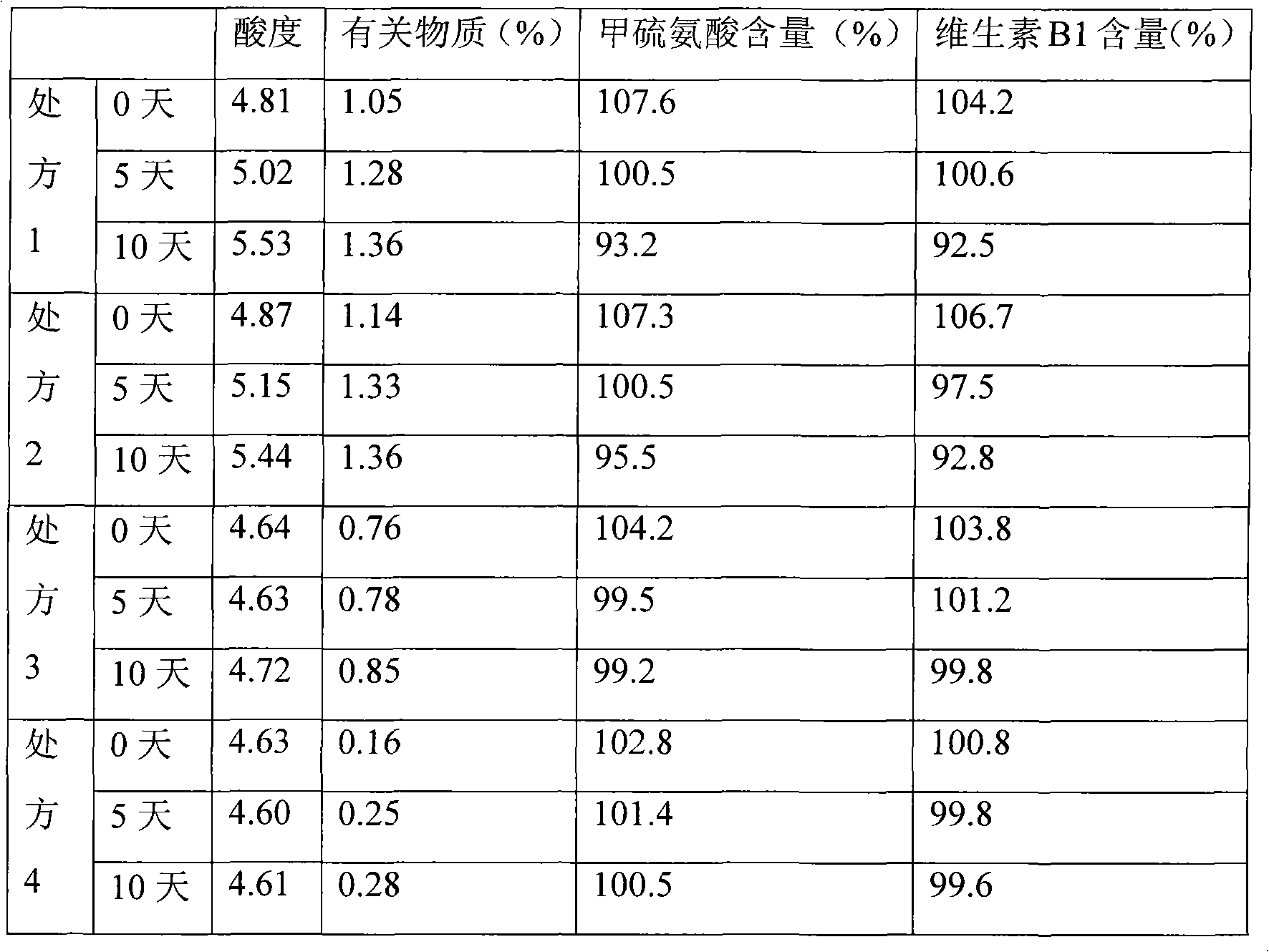

Methionine-vitamin B1 composite injection and preparation method thereof

ActiveCN101810620AReasonable prescriptionGood freeze-drying effectPowder deliveryMetabolism disorderMethionine biosynthesisSorbitol

The invention relates to the medical field, in particular to a methionine-vitamin B1 composite injection and a preparation method thereof. The composite of the invention comprises the following components in parts by weight: 10 parts of methionine, 1 part of vitamin B1, 10-50 parts of sorbitol and 0.001-0.01 part of sodium pyrosulfite. The composite injection of the invention has the advantages of high stability and the like.

Owner:福建康成医药有限公司

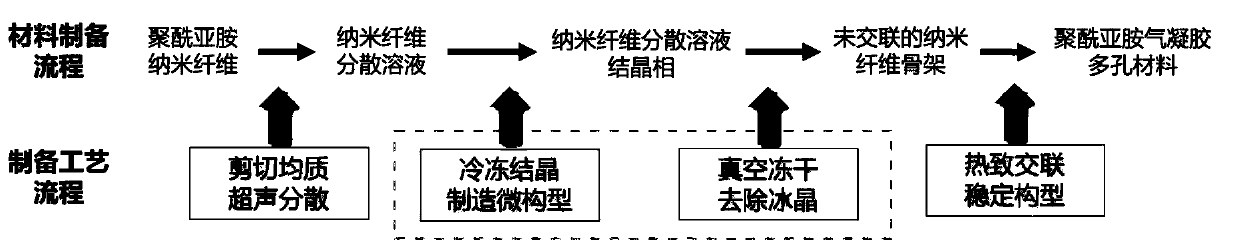

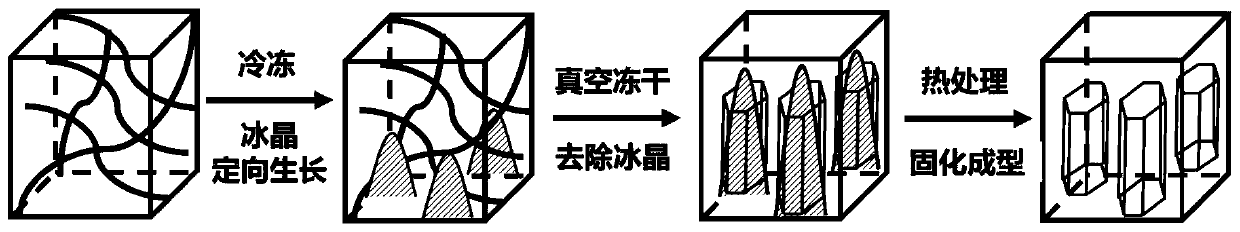

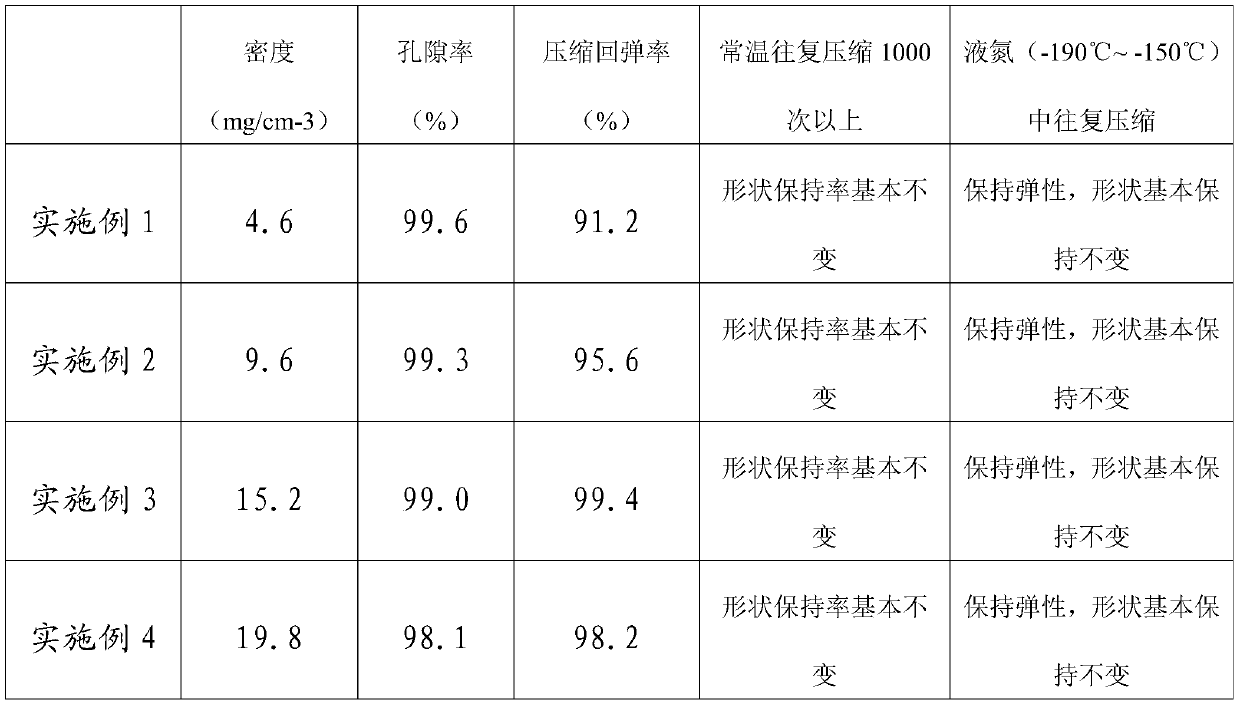

Preparation method of polyimide nanofiber aerogel with controllable microstructure

The invention relates to a preparation method of polyimide nanofiber aerogel with a controllable microstructure. The preparation method is characterized by comprising the following steps: step 1, preparing polyimide into a nanofiber dispersion solution; step 2, carrying out freezing crystallization on the nanofiber dispersion solution to manufacture a micro-configuration so as to obtain a nanofiber dispersion solution crystalline phase; step 3, removing ice crystals of the crystalline phase of the nanofiber dispersion solution to obtain an uncrosslinked nanofiber skeleton; and step 4, heatingthe non-crosslinked nanofiber skeleton to stabilize the configuration, thereby obtaining the polyimide nanofiber aerogel. The freezing nucleation of the solvent is directionally controlled by controlling the freezing speed and the temperature gradient so that the framework construction of the polyimide nanofiber is controlled, and the macroscopic functional characteristics of the material are determined. Compared with a traditional method, the method is simple and convenient and convenient to control technological parameters, and the operation efficiency and the product success rate can be improved.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

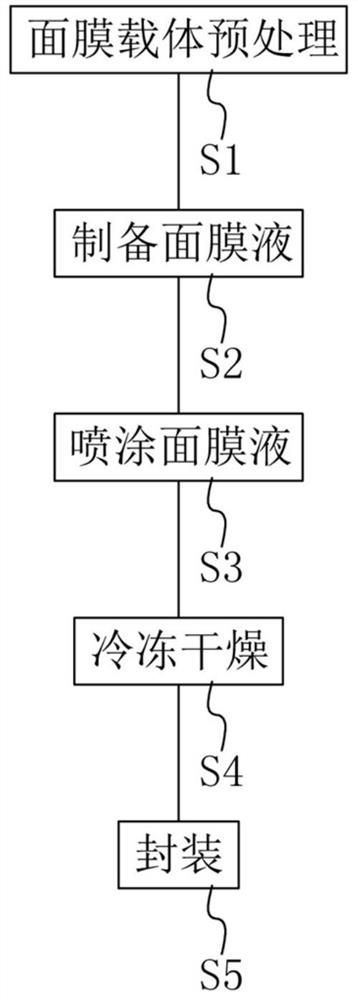

One-stage dynamic freeze-drying method of freeze-dried mask

PendingCN112006920AHigh freeze-drying efficiencyGood freeze-drying effectCosmetic preparationsDrying solid materials without heatFreeze-dryingProcess engineering

The invention discloses a one-stage dynamic freeze-drying method of a freeze-dried mask, relates to the technical field of freeze-drying, and aims at solving the problems that the freeze-drying treatment efficiency is low and the freeze-drying treatment effect is poor. The technical key point is that the one-stage dynamic freeze-drying method of the freeze-dried mask comprises the following steps:preparation of a mask liquid; mask liquid spraying; freeze drying; and package. A proper cooling and freeze-drying procedure is set for a mask carrier, so that the temperature of the mask carrier isdynamically changed in the freezing tunnel, active matters of the mask are reserved in a most proper manner under the condition that the concentration and the vacuum degree of a material system are not changed, and the advantages of higher freeze-drying treatment efficiency and better freeze-drying treatment effect are achieved.

Owner:广东柏文生物科技股份有限公司

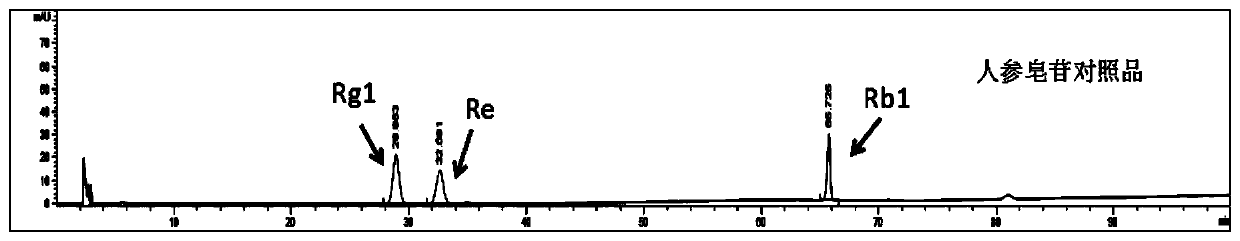

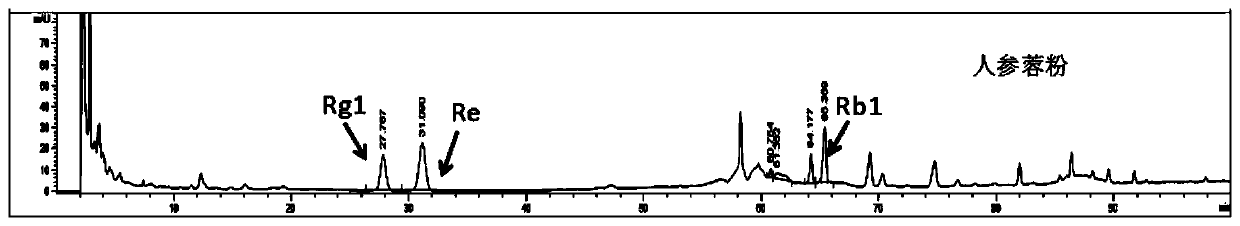

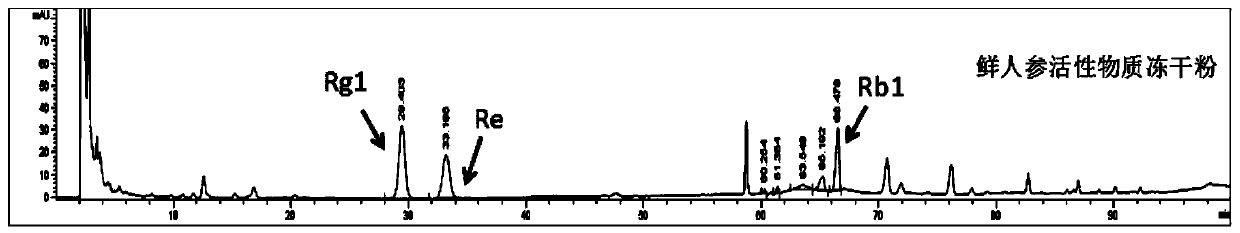

Preparing method of fresh ginseng active substance

InactiveCN109999072AStrong tasteIncrease profitCosmetic preparationsToilet preparationsFreeze dryTraditional Chinese medicine

The invention relates to a preparing method of a fresh ginseng active substance, and belongs to the technical field of traditional Chinese medicine decoction piece and food processing. The preparing method comprises the steps that fresh ginseng is taken as a raw material, washed thoroughly with water and squeezed to obtain an extraction liquor A and smashed ginseng A; the smashed ginseng A is divided into smashed ginseng B and smashed ginseng C, water is added to the smashed ginseng B for soaking, and squeezing and solid-liquid separation are conducted to obtain an extraction liquor B and smashed ginseng D; the extraction liquor B is transferred into the smashed ginseng C, and soaking, squeezing and solid-liquid separation are conducted to obtain an extraction liquor and smashed ginseng E;the processes are repeated, the obtained extraction liquors are merged, after filtering, a sweetening agent is added, and then refreezing and smashing are conducted to obtain fresh ginseng active freeze-dried powder; all the obtained smashed ginseng is merged, dried and smashed to obtain smashed ginseng powder. By means of the preparing method, the problems are solved that the storage and transportation cost for traditional ginseng decoction pieces and fresh ginseng is high, effective ingredients run off in the preparing course, and active substances are converted in the heating course; the use is more convenient, the processing course is simple, the water addition amount is small, the freeze-drying efficiency is improved, and production can be amplified.

Owner:康美(北京)药物研究院有限公司 +2

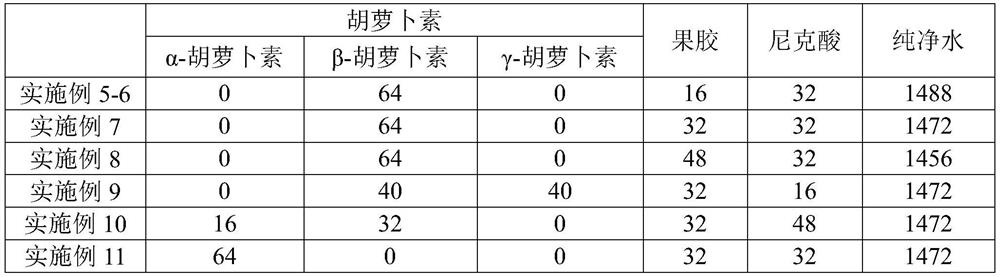

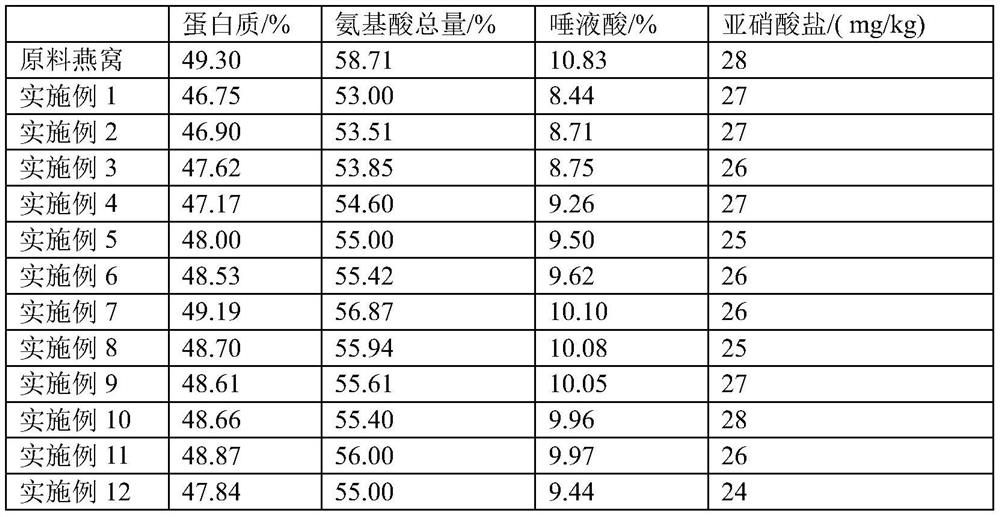

Freeze-dried cubilose and processing technology thereof

ActiveCN113647615AEasy to eatGood freeze-drying effectFood freezingFood ingredientsBiotechnologyDried food

The invention relates to the technical field of freeze-dried food, in particular to freeze-dried cubilose and a processing technology thereof, and the processing technology of the freeze-dried cubilose comprises the following processing steps: cleaning, soaking and dehydrating fresh cubilose; steaming: steaming the dehydrated cubilose at 80-100 DEG C for 2-5 minutes, and cooling the cubilose to 23 + / - 2 DEG C to obtain wet cubilose; freeze-drying: freeze-drying the wet cubilose at -50 to 20 DEG C under the absolute vacuum degree of 0.5 + / - 0.2 Pa until the water content is not greater than 3%, so as to obtain the freeze-dried cubilose. The freeze-dried cubilose processed by the method can be eaten after being soaked in hot water for about 5 minutes before being eaten, is convenient to eat, has relatively high nutritional ingredients, and is fine, smooth, soft, elastic and relatively good in mouth feel.

Owner:北京同仁堂参茸中药制品有限公司

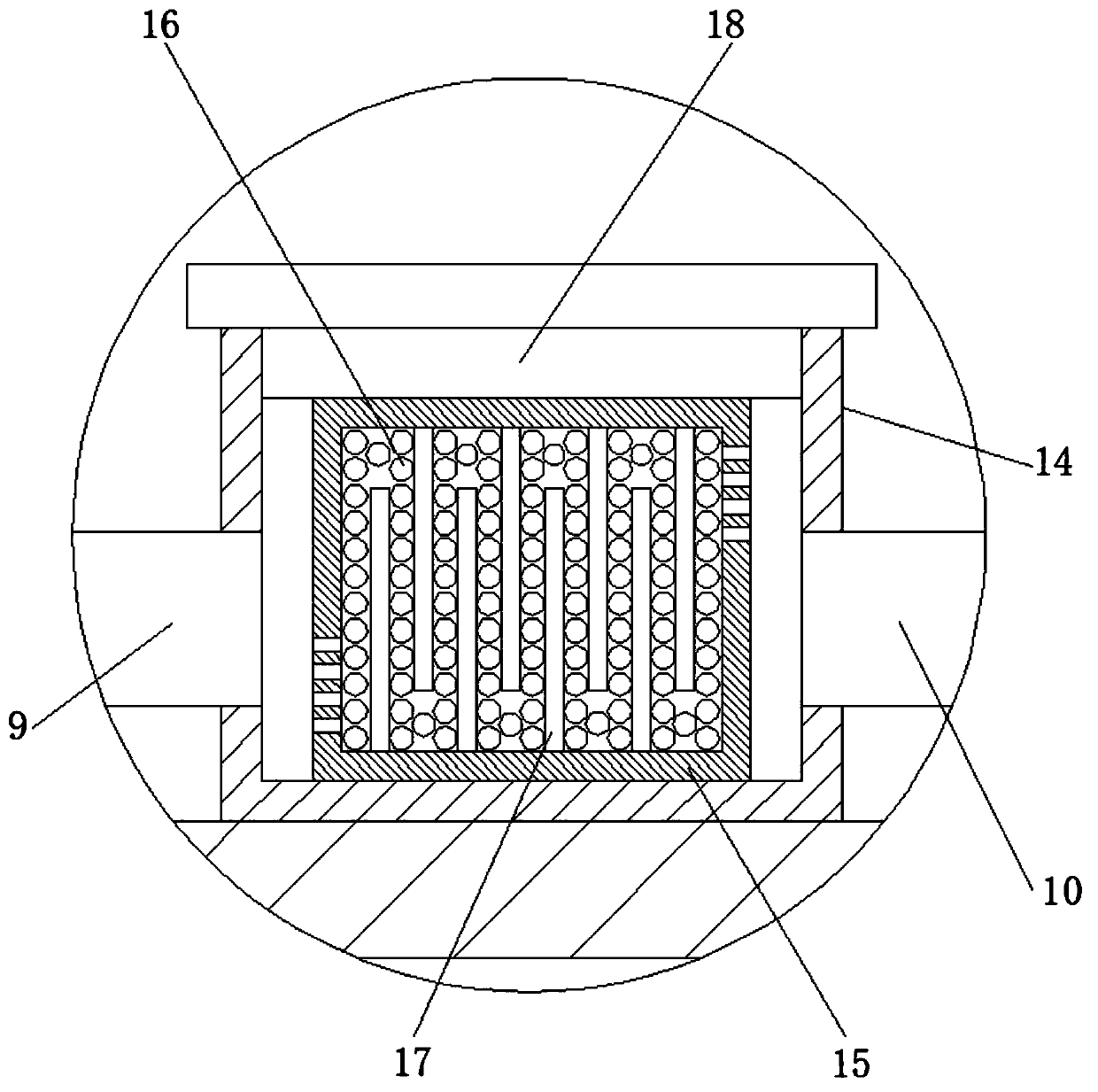

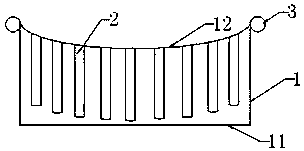

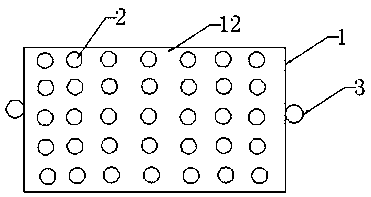

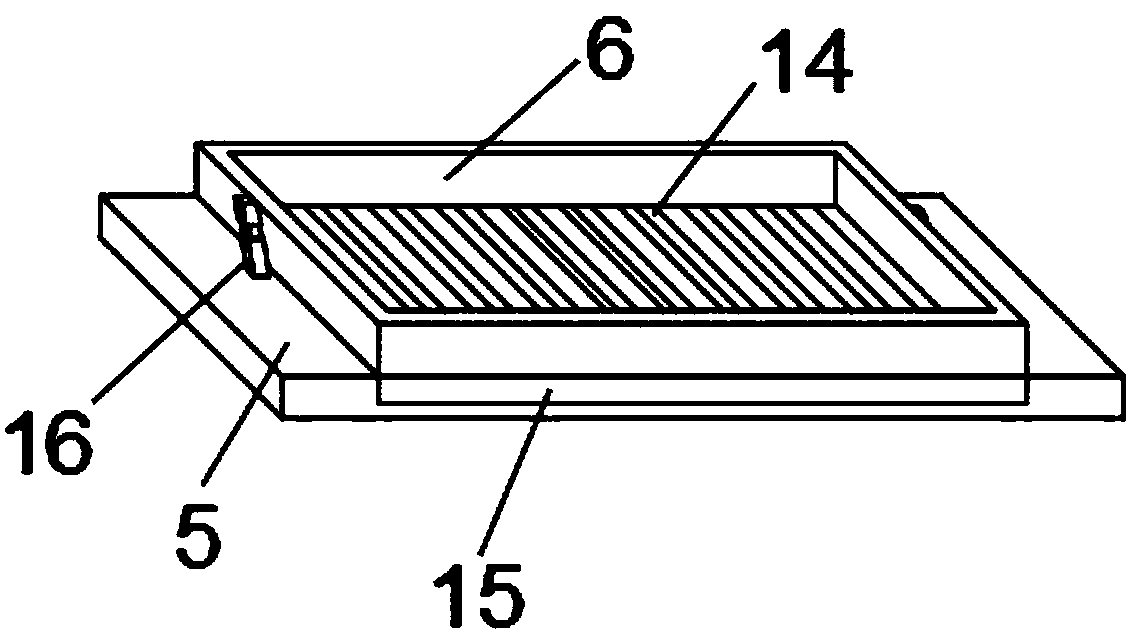

Thermal-uniformity tray for freeze dryer

InactiveCN108413715ASimple structureReasonable designDrying solid materials without heatDrying chambers/containersBiochemical engineeringFreeze-drying

The invention discloses a thermal-uniformity tray for a freeze dryer. The thermal-uniformity tray for the freeze dryer comprises a tray main body, wherein the tray main body is of a solid rectangularstructure, the bottom surface contacting with the partition of the freeze dryer, of the tray main body, is a plane, and the top surface of the tray main body is a concave surface; a plurality of uniformly-distributed groove holes are chiseled in the tray main body, the bottom end of each groove hole is a blind hole, the top end of the groove hole is of an open structure, and the vertical distancebetween the blind hole end of each groove hole and the bottom surface of the tray main body is gradually increased from the middle part of the tray main body to the four sides of the tray main body; and the height of each groove hole is the same. The thermal-uniformity tray for the freeze dryer is simple in structure, and reasonable and novel in design; the heat transfer speed at any position on the whole tray main body is the same through the own structure of the tray main body and the design that the groove holes for holding penicillin bottles are formed at positions on the tray main body, so that the same freeze drying speed for a sample to be subjected to freeze drying, at any position on the whole tray main body, is ensured, and the freeze drying effect is improved.

Owner:苏州布莱尔仪器有限公司

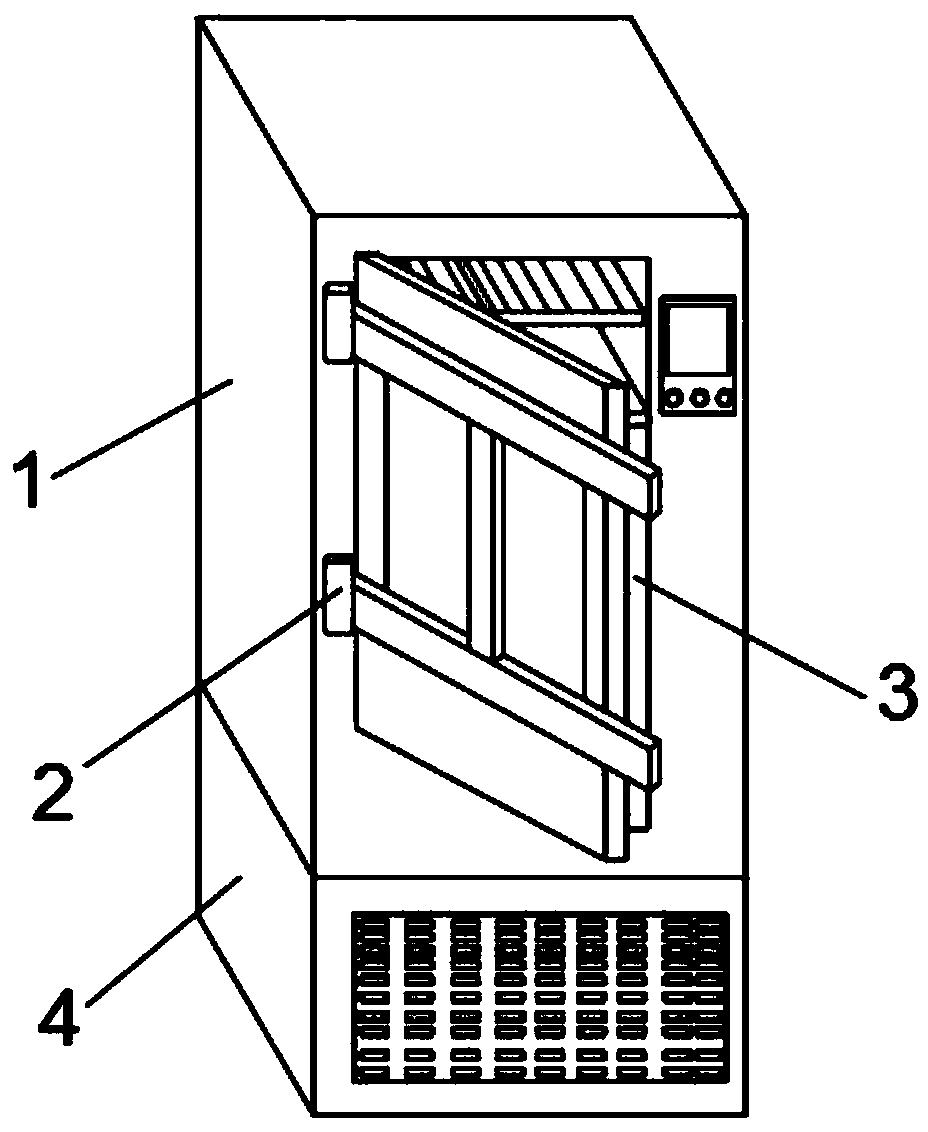

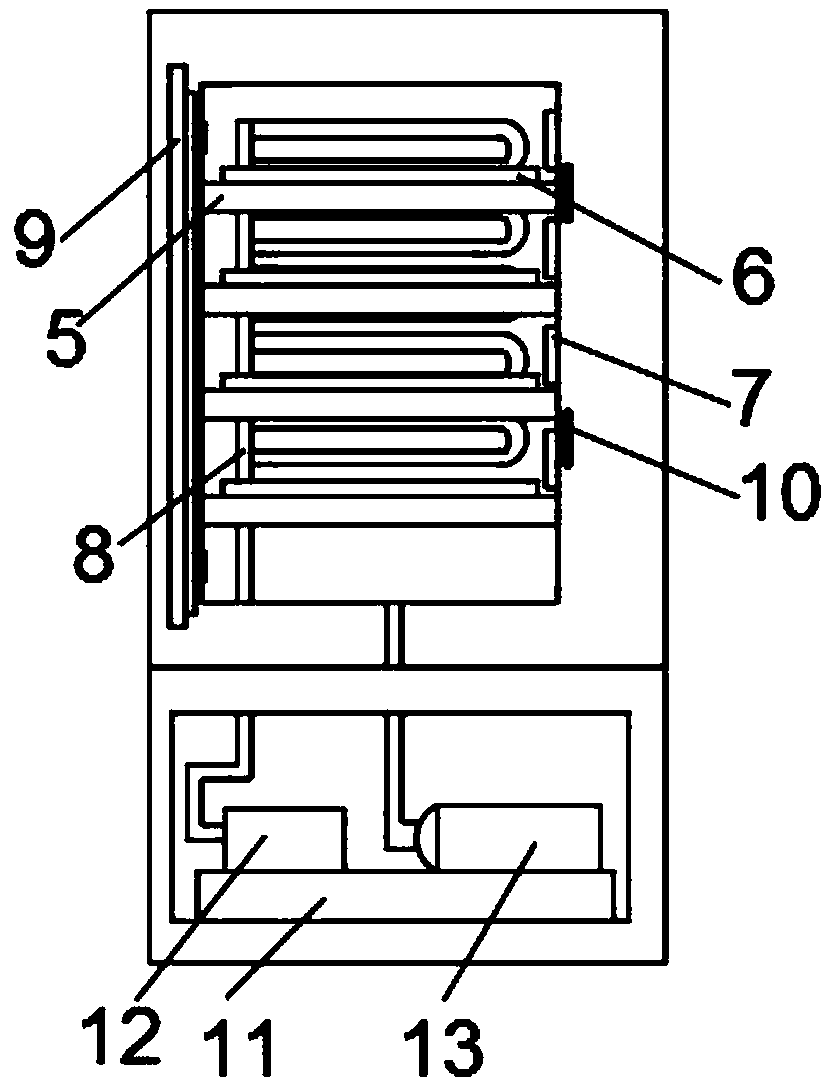

Freezer dryer for protein solution freeze-drying

InactiveCN109631506AChange tilt anglePlacement Angle AdjustmentDrying solid materials without heatDrying chambers/containersProtein solutionSurface mounting

The invention discloses a freezer dryer for protein solution freeze-drying. The freezer dryer for protein solution freeze-drying comprises a freeze-drying box and a machine case, and the lower surfaceof the freeze-drying box is fixedly connected with the upper surface of the machine case; a movable frame is arranged on the front surface of the freeze-drying box, and a sealing door is fixedly installed on the surface of the movable frame; freezing pipes are installed on the back surface of the interior of the freeze-drying box; partition plates are arranged between the two sides of the inner surface of the freeze-drying box, and containing boxes are fixedly installed on the upper surfaces of the partition plates; a plurality groups of heating pipes are arranged on the two sides of the inner surface of the freeze-drying box; and an encryption assembly is installed in the inner surface of one side of the freeze-drying box in an embedded mode. According to the freezer dryer for protein solution freeze-drying, the angles of the containing boxes can be conveniently adjusted in the freeze-drying period of a protein solution, and the protein solution can be uniformly heated and frozen inthe freeze-drying period; and the sealing property of the sealing door can be improved, therefore, the sealing property of the whole machine is better, the protein solution freeze-drying effect is better, and the using effect is significant.

Owner:安徽环球基因科技有限公司

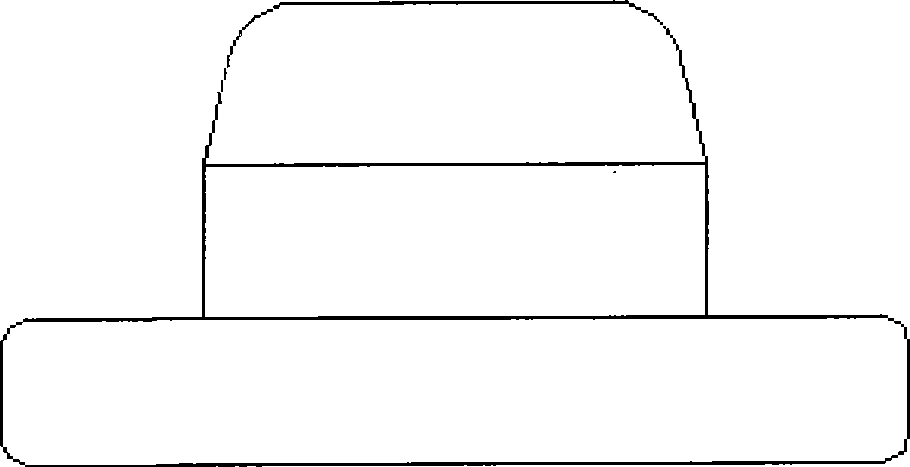

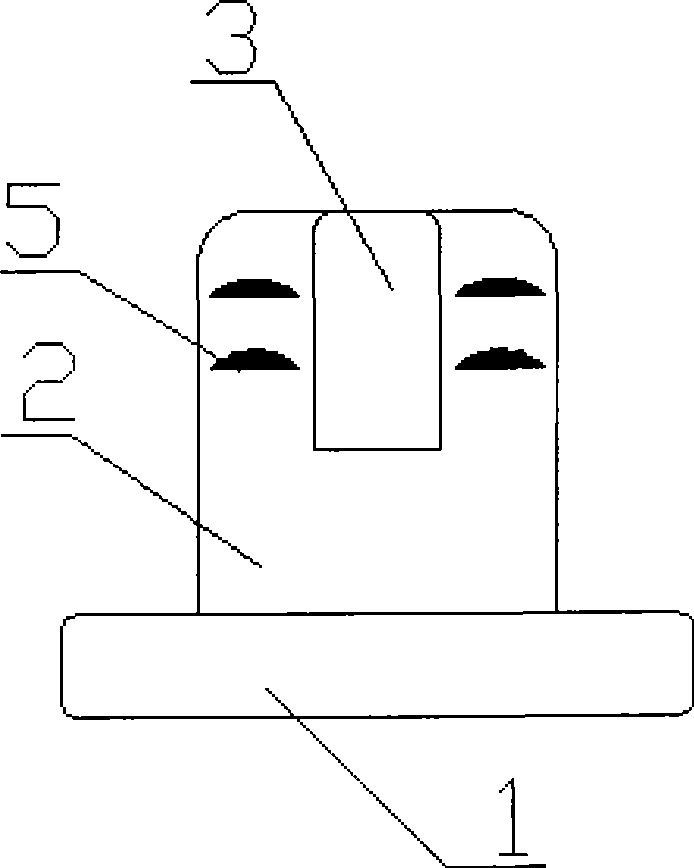

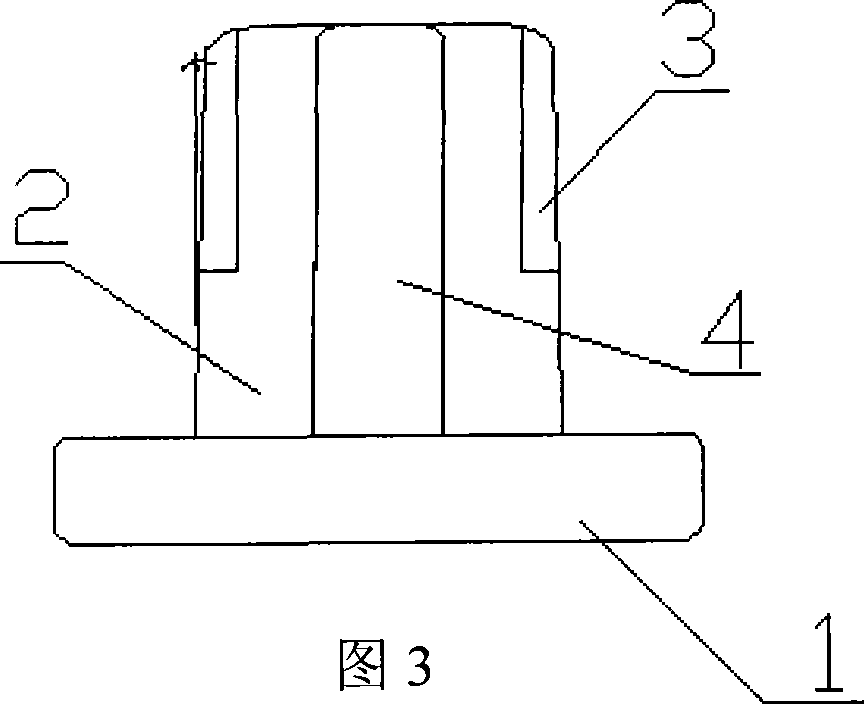

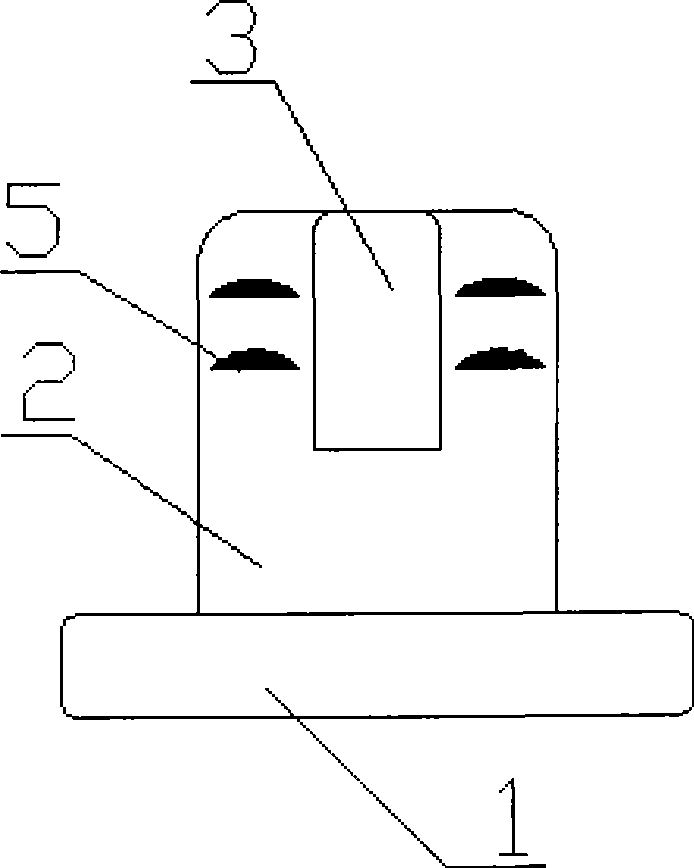

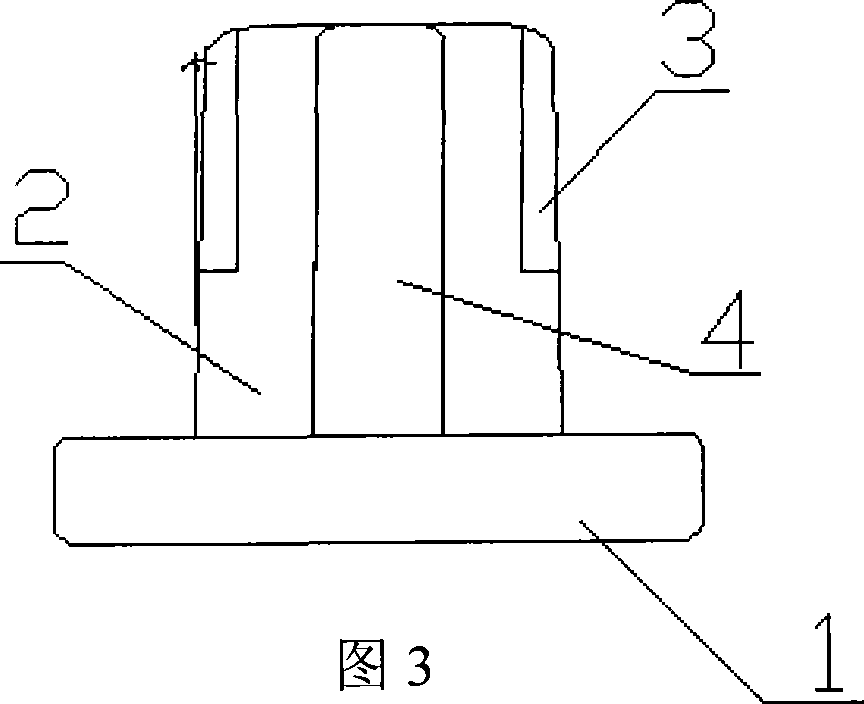

Novel medicinal bottle stopper for lyophilized powder formulation

InactiveCN101411671AImprove air tightnessSimple structurePharmaceutical containersMedical packagingBiochemical engineeringFreeze-drying

The invention relates to a bottle cap, in particular to a novel medical freeze-dried bottle stopper, which comprises a bottle stopper of which a center is provided with a round hole, and is characterized in that the periphery of the bottle stopper is uniformly provided with four round vent grooves, an outer wall of the bottle stopper is provided with double wedges, and a neck of the bottle stopper is provided with a 3 DEG guide angle. The novel medical freeze-dried bottle stopper has the advantages of simple structure and convenient use, can ensure that a packaging bottle has good air tightness, has the advantages of good freeze-drying effect and high production efficiency during production and packaging processes of freeze-dried powder injection, is favorable for the quick vacuum aseptic packaging of medicines, and improves the quality of products and the efficiency.

Owner:应城市恒天药业包装有限公司

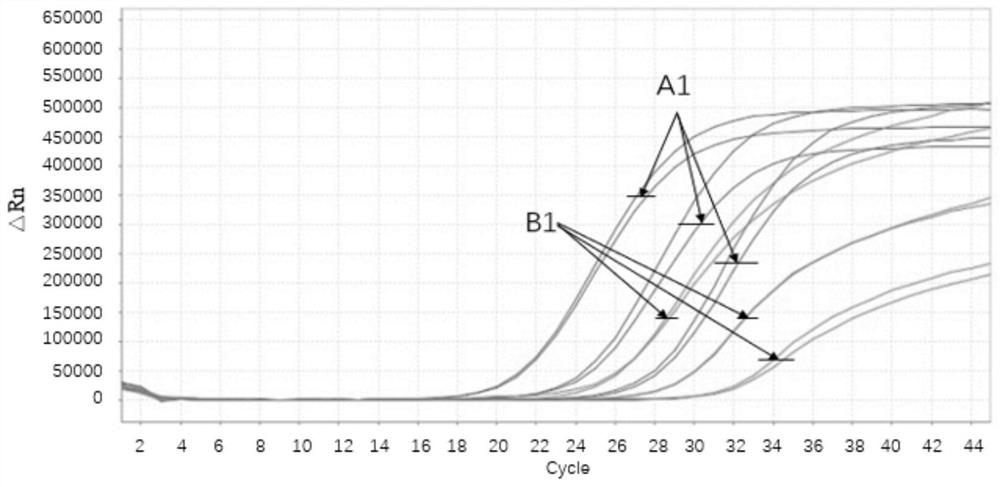

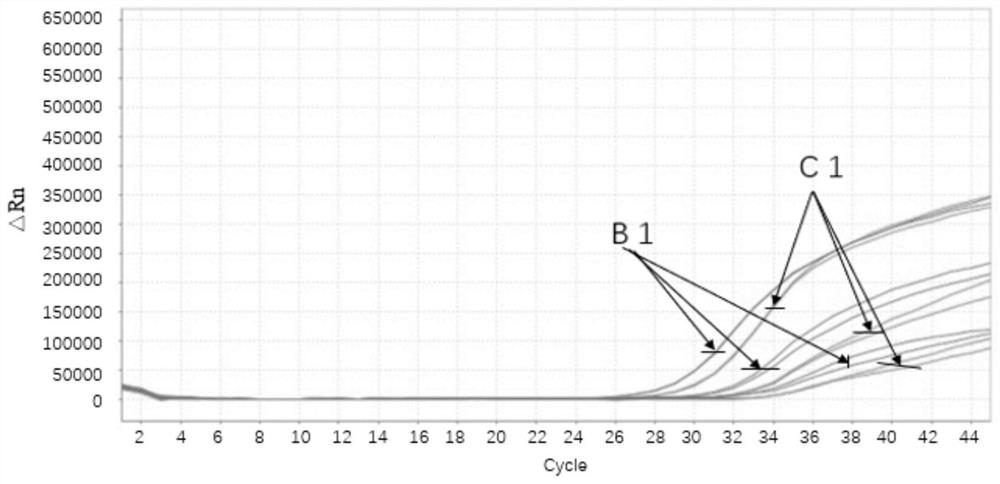

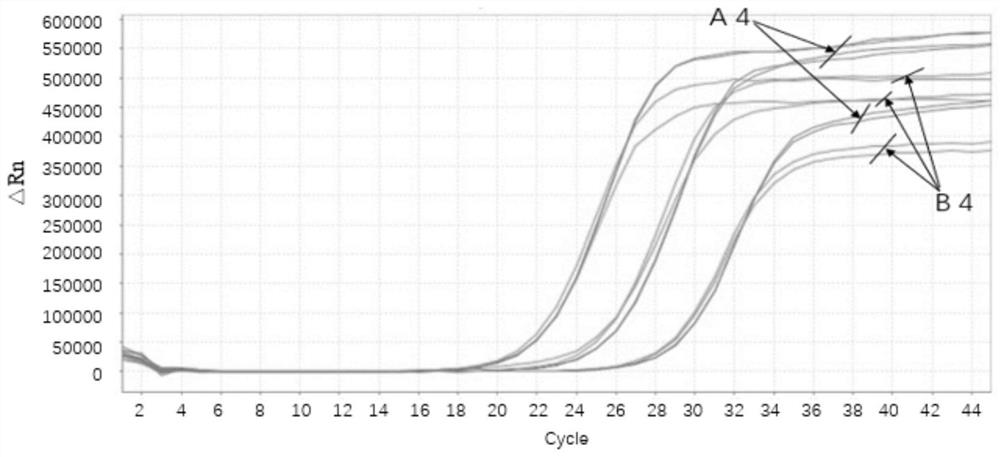

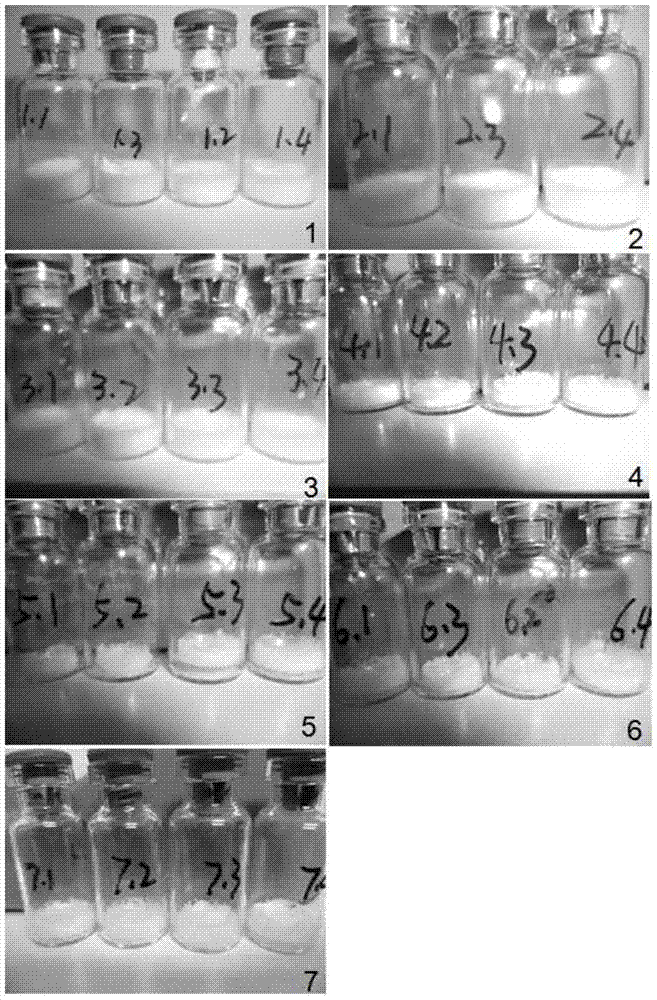

A kind of freeze-drying protection agent and freeze-drying method of RNA amplification reaction reagent

ActiveCN111560417BGuaranteed stabilityGood freeze-drying effectMicrobiological testing/measurementSucroseActive agent

The invention discloses a freeze-drying protective agent and a freeze-drying method of an RNA amplification reaction reagent, and relates to the technical field of biology. The freeze-drying protective agent is prepared from the following components: 5 to 20 percent of trehalose, 5 to 15 percent of mannitol, 0.5 to 5mg / mL of bovine serum albumin, 0.05 to 0.5 percent of a surfactant and 0.01 to 0.05 percent of a defoaming agent. In the implementation process, a small amount of lentinan and cane sugar are added into a freeze-dried reagent; it is found that after addition, the freeze-drying effect of the freeze-dried reagent can be effectively improved, the freeze-dried reagent can be stored for a long time under the normal temperature condition by controlling the concentration ratio of trehalose to lentinan to sucrose, and the freeze-driedreagent still has high sensitivity after being stored for 6 months under the room temperature condition.

Owner:INTEGRATED BIOSYSTEMS CO LTD +1

Lactobacillus freeze-drying protective agent as well as preparation method and application thereof

InactiveCN112342172AIncrease stickinessAvoid damageBacteriaMicroorganism based processesBiotechnologyFreeze-drying

The invention discloses a lactobacillus freeze-drying protective agent as well as a preparation method and application thereof. The lactobacillus freeze-drying protective agent comprises 7%-10% of maltose, 3%-6% of polyethylene glycol, 4%-8% of bovine serum albumin, 0.3%-0.8% of glutathione and 0.05%-0.2% of cobalamin. Compared with the prior art, the protective agent provided by the invention caneffectively improve the survival rate (the survival rate is greater than 96%) and the effective viable count (the viable count of the bacterial powder is greater than 10<11>cfu / g) of lactobacillus after vacuum freeze drying, and prolongs the shelf life of the bacterial powder (the viable count is greater than 10<11>cfu / g and the loss rate is less than 10% after the bacterial powder is stored at room temperature).

Owner:SHENYANG RES INST OF CHEM IND

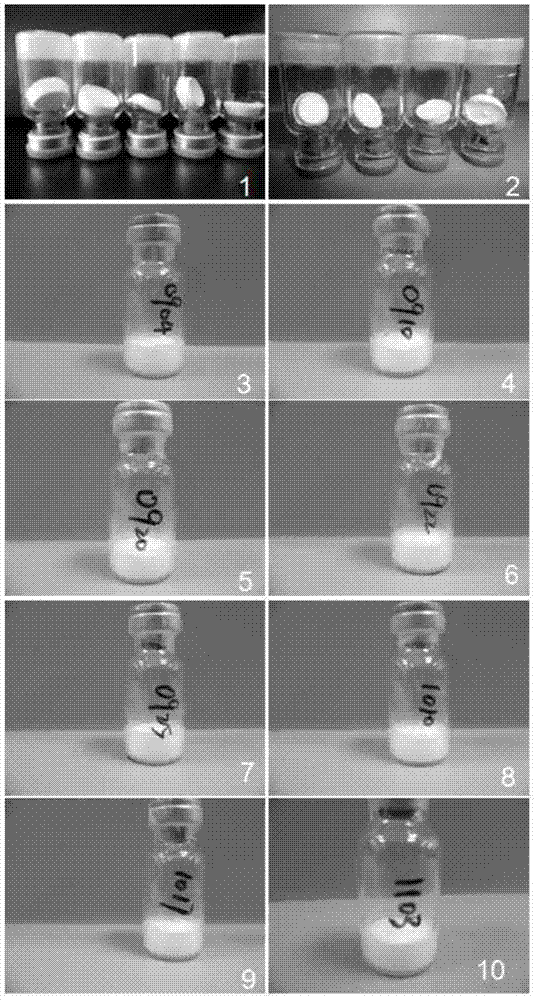

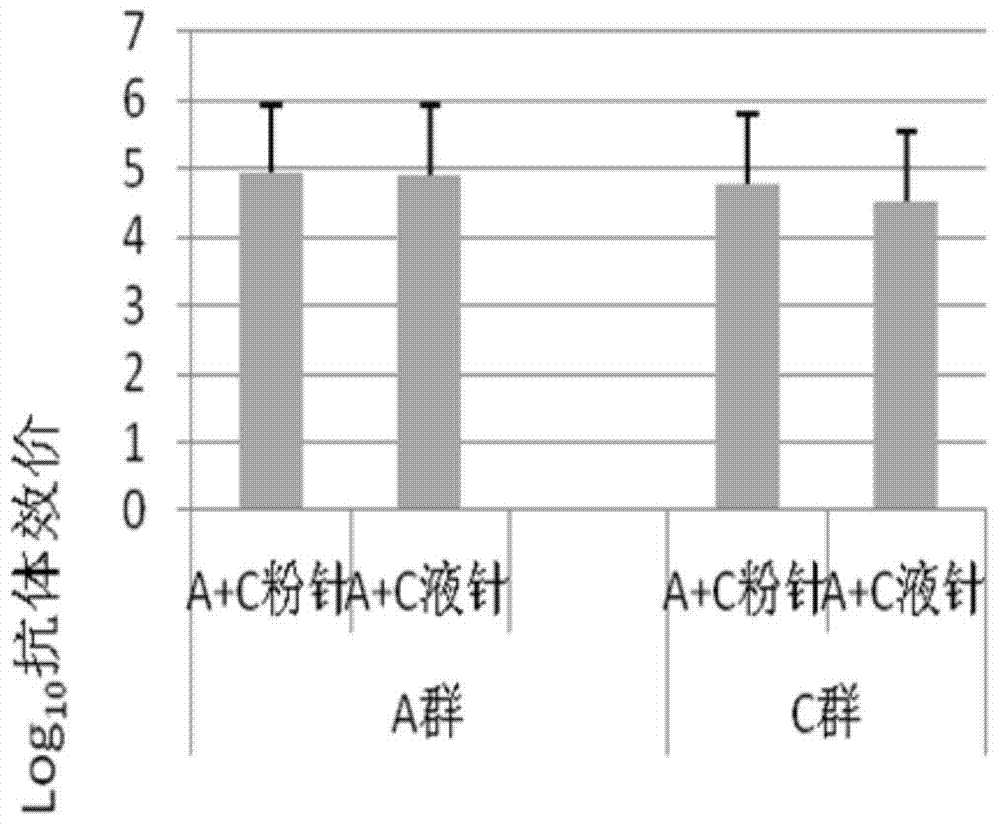

Multivalent meningococcal preparation kit, vaccine preparation and preparation method thereof

ActiveCN104958759BEasy to detectStable maintenance of effective antigenic activityAntibacterial agentsPowder deliveryFreeze-dryingMeningococcal carriage

Owner:CANSINO BIOLOGICS INC

Dynamic interactive vacuum low-temperature non-woven fabric dehydration method

InactiveCN112064265AGuaranteed not to crystallizeReduce moisture contentLiquid/gas/vapor removalTextile treatment by spraying/projectingPhysical chemistryNonwoven fabric

The invention relates to a dynamic interactive vacuum low-temperature non-woven fabric dehydration method. The method comprises the following steps that a mask stock solution is atomized through a spraying tunnel, and is uniformly sprayed on non-woven mask cloth; and the non-woven mask cloth covered with the mask liquid is freeze-dried on a freeze-drying tunnel, and water in the mask liquid on thenon-woven mask cloth is sublimated and removed in the freeze-drying tunnel. According to the dynamic interactive vacuum low-temperature non-woven fabric dehydration method, the non-woven fabric is dewatered in a multi-section vacuum low-temperature mode, the mask liquid is condensed at the low temperature, meanwhile, the pressure is reduced, the boiling point of water is changed, the water in themask liquid is sublimated and pumped away, and therefore liquefaction of the mask liquid during water sublimation is avoided; and it is guaranteed that the non-woven fabric is not crystallized afterdehydration, the water content of the non-woven fabric after dehydration is reduced, and the freeze-drying effect of the non-woven fabric is improved.

Owner:广东柏文生物科技股份有限公司

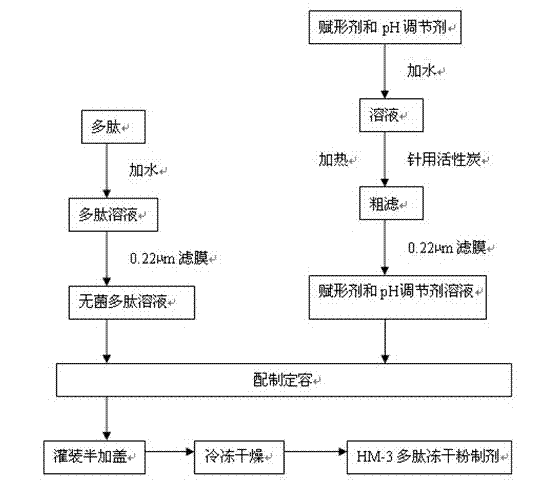

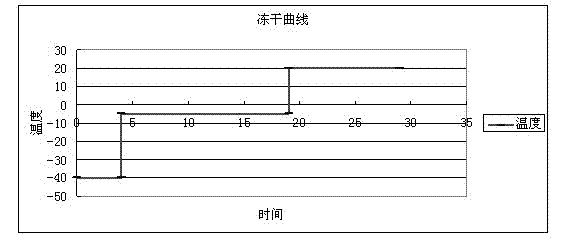

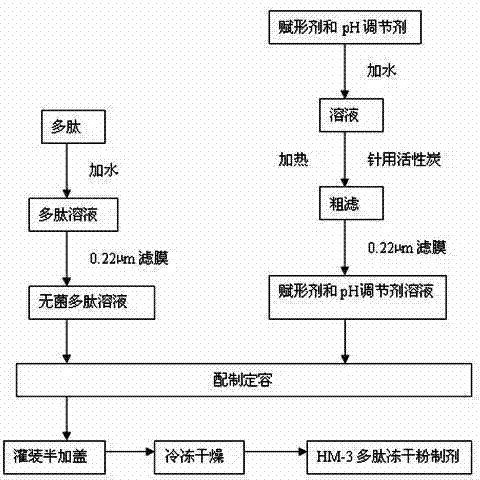

HM-3 polypeptide freeze-dried powder preparation and preparation method thereof

ActiveCN102178656BGood freeze-drying effectReduce moisturePowder deliveryPeptide/protein ingredientsFreeze-dryingFilter paper

The invention relates to an HM-3 polypeptide freeze-dried powder preparation and a preparation method thereof, relating to HM-3 polypeptides. The preparation method comprises the steps of: quantitatively preparing a solution from HM-3 polypeptide and minor ingredients, removing carbon through filter paper and filtering aseptically, then charging a clean and aseptic ampoule according to the specification of 0.5-5ml of per preparation, sending to a freeze dryer for freeze-drying for 20-30 h and then taking out; and covering and carrying out quality detection, obtaining the HM-3 polypeptide freeze-dried powder preparation after the quality is qualified. The HM-3 polypeptide freeze-dried powder preparation prepared by using the method has high activity and purity and better medical effect, and is convenient for carrying and storing.

Owner:BEIJING SAISHENG PHARMA

Novel medicinal bottle stopper for lyophilized powder formulation

InactiveCN101411671BImprove air tightnessSimple structurePharmaceutical containersMedical packagingFreeze-dryingBiochemical engineering

The invention relates to a bottle cap, in particular to a novel medical freeze-dried bottle stopper, which comprises a bottle stopper of which a center is provided with a round hole, and is characterized in that the periphery of the bottle stopper is uniformly provided with four round vent grooves, an outer wall of the bottle stopper is provided with double wedges, and a neck of the bottle stopper is provided with a 3 DEG guide angle. The novel medical freeze-dried bottle stopper has the advantages of simple structure and convenient use, can ensure that a packaging bottle has good air tightness, has the advantages of good freeze-drying effect and high production efficiency during production and packaging processes of freeze-dried powder injection, is favorable for the quick vacuum aseptic packaging of medicines, and improves the quality of products and the efficiency.

Owner:应城市恒天药业包装有限公司

Bird's nest freeze-drying equipment and freeze-drying process thereof

InactiveCN114459212AImprove uniformityQuality improvementDrying solid materials without heatDrying chambers/containersFreeze-dryingStructural engineering

The invention relates to the technical field of freeze-drying, and discloses bird's nest freeze-drying equipment and a freeze-drying process thereof.The bird's nest freeze-drying equipment comprises a freeze-drying box, a freeze-drying cavity with an opening in one side is formed in the freeze-drying box, and a plurality of partition plates are arranged in the freeze-drying cavity at intervals; mounting plates with the number equal to that of the partition plates are fixed to the cavity walls of the two opposite sides of the freeze-drying cavity respectively, the partition plates are arranged between every two adjacent mounting plates at the same horizontal height in a sliding mode, and limiting pieces used for preventing the partition plates from moving out of the freeze-drying cavity are connected to the freeze-drying box; each mounting plate is slidably provided with a length-adjustable shifting rod, the shifting rods are located on the upper sides of the partition plates close to the shifting rods, and the mounting plates are provided with first driving parts used for driving the shifting rods to move horizontally and second driving parts used for driving the shifting rods to move vertically. The edible bird's nest cooling device has the effects of high edible bird's nest cooling uniformity and good finished product quality.

Owner:上海拓纷机械设备有限公司

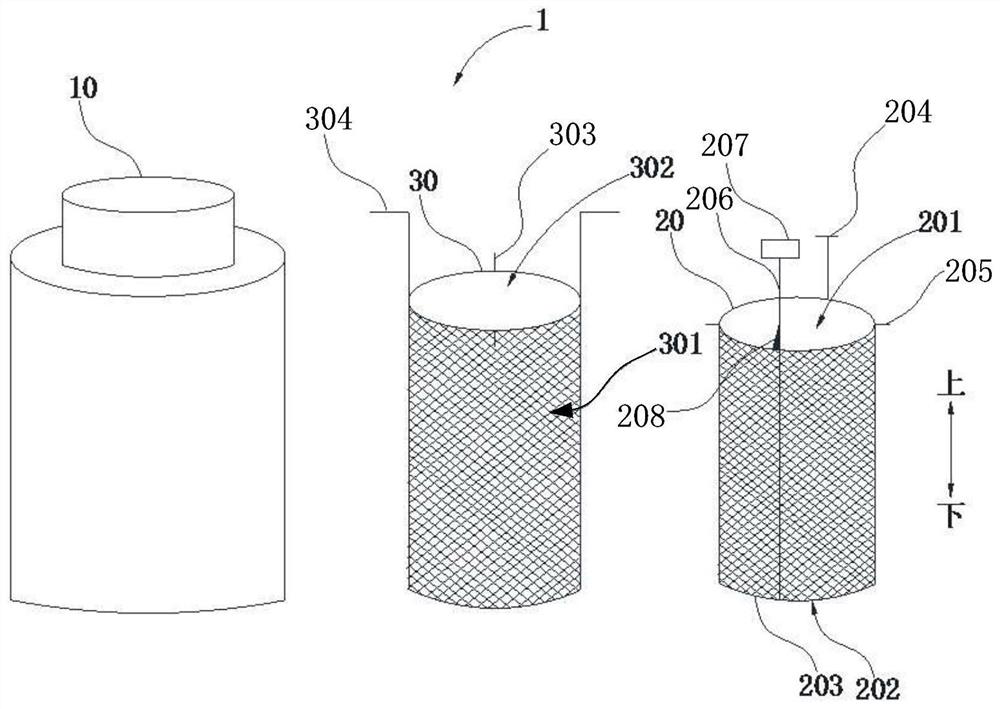

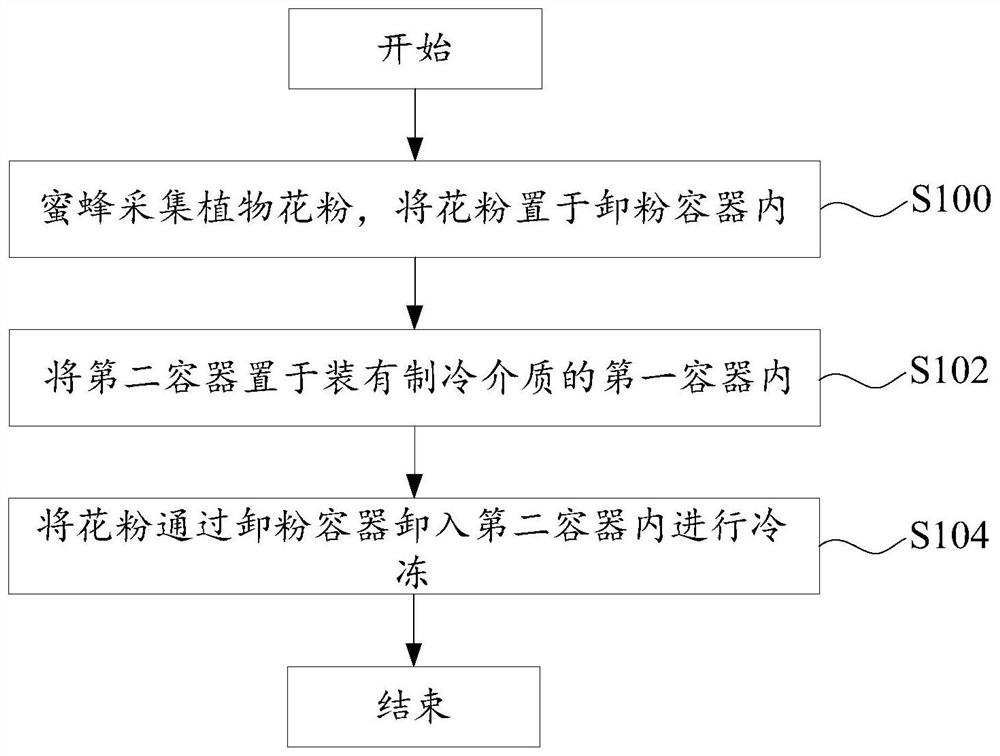

Preparation device and preparation method for pollen used for pollination

InactiveCN111685035AAchieve freezingHigh activityDead plant preservationPlant genotype modificationEngineeringPollination

The invention discloses a preparation device and a preparation method for pollen used for pollination. The preparation device for the pollen used for pollination comprises a first container, a powderunloading container and a second container, wherein refrigeration media are loaded in the first container; the powder unloading container is provided with a first material inlet and a first material outlet; the first material outlet is provided with a bottom plate; the bottom plate is suitable for moving relative to the first material outlet to open or close the first material outlet; the second container is arranged in the first container; in addition, the second container is provided with a second material inlet, and the second material inlet is used for the powder unloading container to unload the pollen to the second container; and the second container and the powder unloading container are independently provided with mesh openings, wherein the diameter of each mesh opening is smallerthan the diameter of the pollen. According to the preparation device for the pollen used for pollination, when the powder unloading container unloads the pollen, the pollen keeps contact with the refrigeration media all the time, so that the pollen can receive a freezing function of the refrigeration media to a maximum degree, the activity of the pollen is guaranteed so as to be favorable for realizing a purpose of quickly finishing a dewatering process, and the preparation efficiency of the pollen used for pollination is effectively improved.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

Acellular DPT/Haemophilus influenzae type b-meningococcal ac combination vaccine

ActiveCN102813917BGood freeze-drying effectRelieve painAntibacterial agentsBacterial antigen ingredientsDiseaseTetanus

The invention provides a diphtheria, tetanus and acellular pertussis / Haemophilus influenzae type b - group A and C meningococcus combined vaccine, which has the characteristics of high safety, high efficacy, high controllability and prevention of multiple diseases through one injection, satisfies relevant requirements on absorbed diphtheria, tetanus and acellular pertussis combined vaccines, Haemophilus influenzae type b combined vaccines and group A and C meningococcus combined vaccines in the Third Part of Chinese Pharmacopoeia (2010) and proposed Rules on Production and Inspection of Diphtheria, Tetanus and acellular Pertussis / Haemophilus influenzae Type b - Group A and C Meningococcus Combined Vaccines, and achieves an effect of putting into practical application.

Owner:WUHAN INST OF BIOLOGICAL PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com