Freeze-drying equipment for food processing

A food processing and freeze-drying technology, applied in lighting and heating equipment, drying solid materials without heating, drying, etc., can solve the problems of slow freeze-drying efficiency and inability to evenly heat food, and achieve better use effect and dehydration The effect of better effect and faster evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

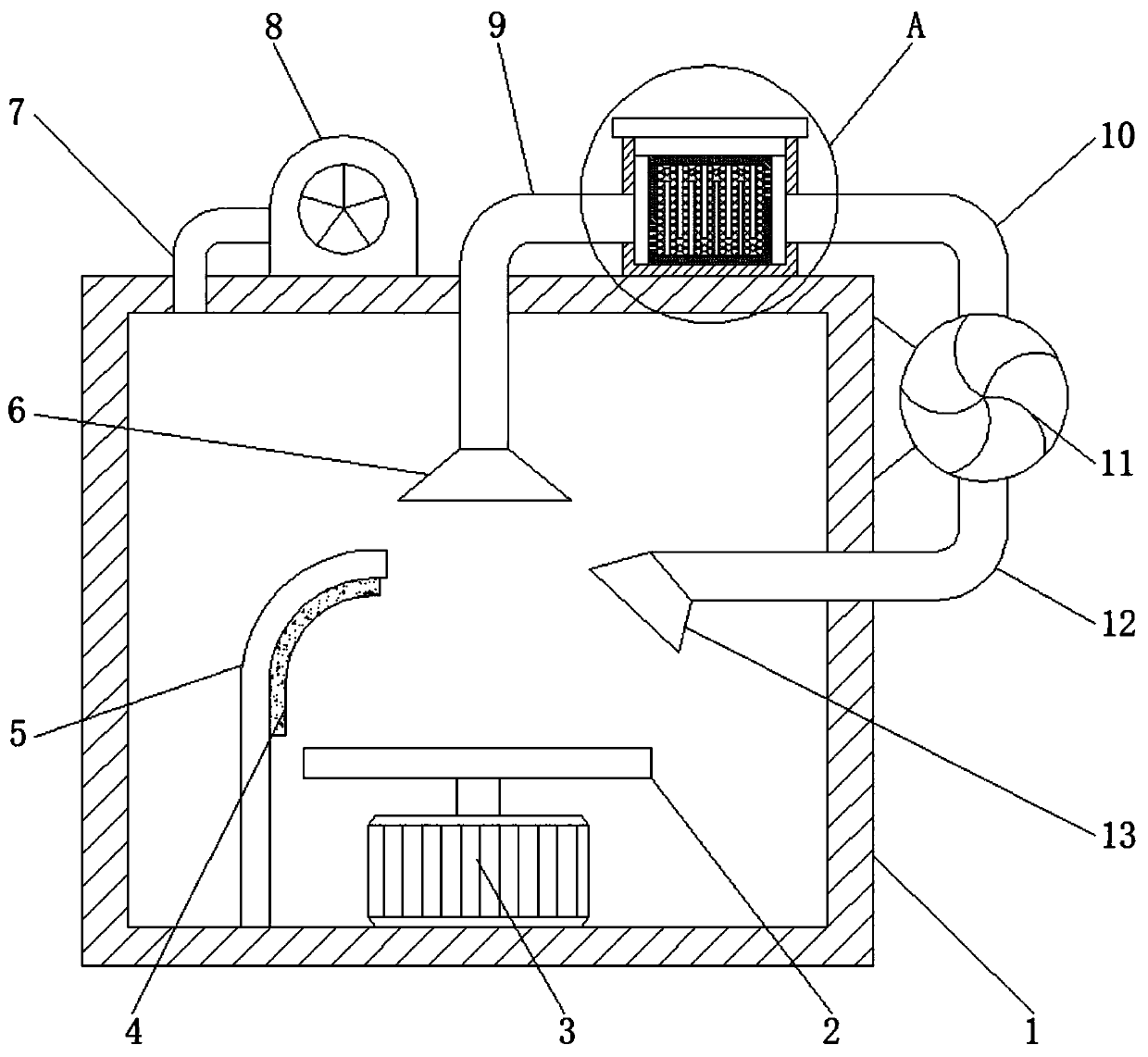

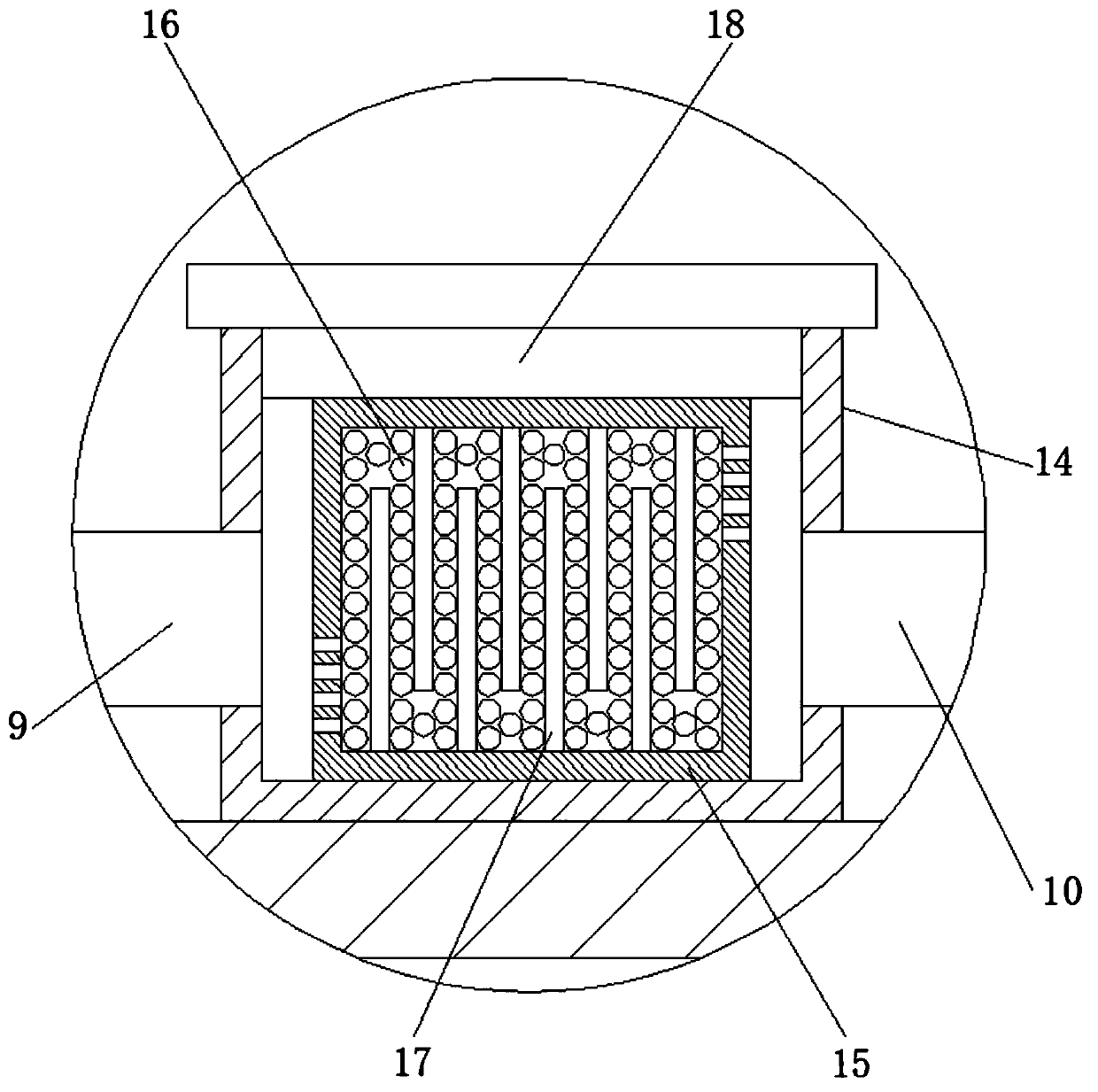

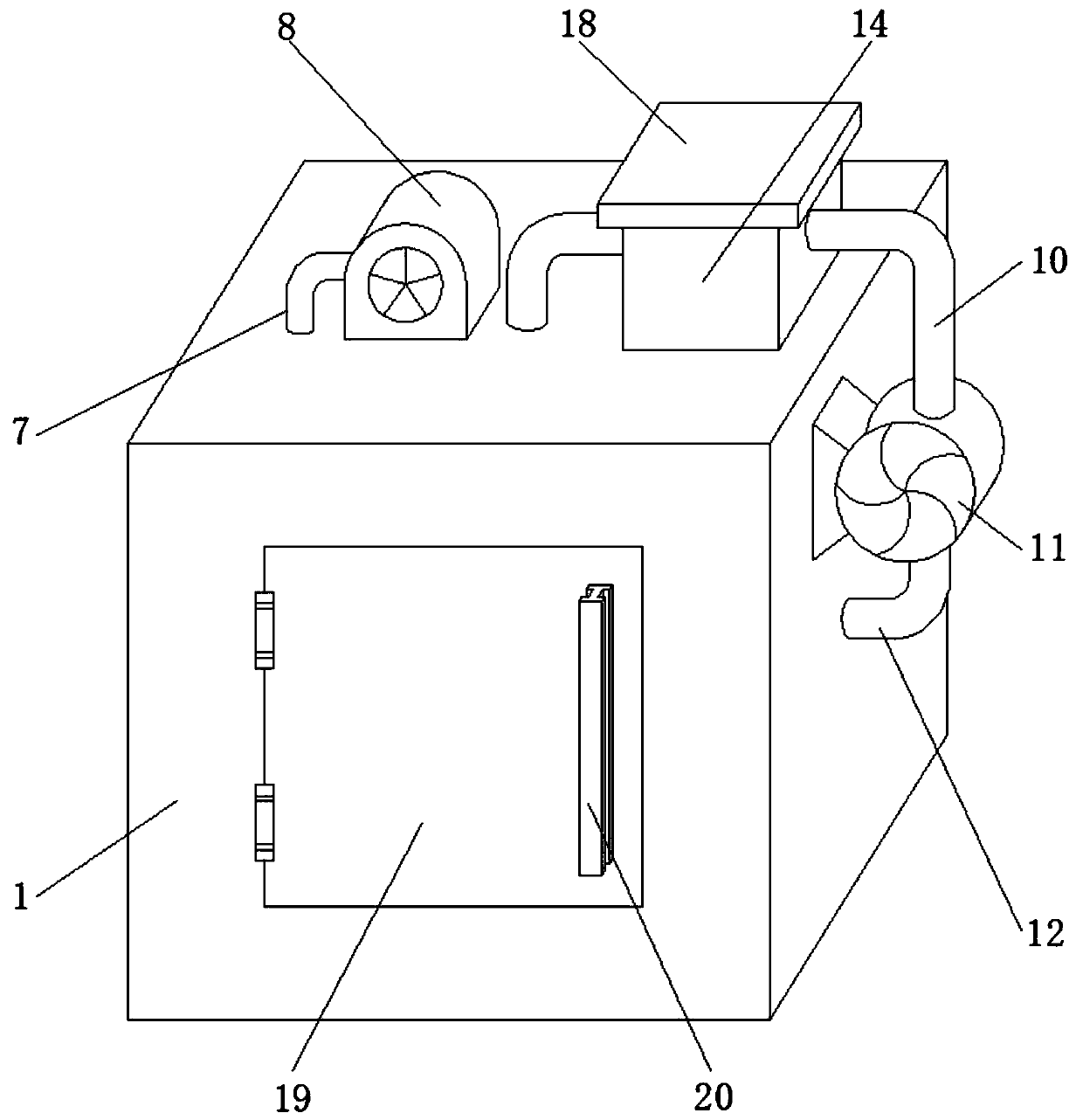

[0027] refer to Figure 1-3 , a kind of freeze-drying equipment for food processing, comprising a freeze-drying box 1, the bottom inner wall of the freeze-drying box 1 is connected with a motor 3 by bolts, and one end of the output shaft of the motor 3 is provided with a turntable 2, and the top outer wall of the freeze-drying box 1 is welded Fixed frame 5 is arranged, and one side outer wall of fixed frame 5 is provided with heating plate 4, and the top outer wall of freeze-drying box 1 is connected with vacuum pump 8 by bolt, and one side outer wall of vacuum pump 8 is provided with air extraction pipe 7, and the air extraction pipe 7 One end communicates with freeze-drying box 1, and one side outer wall of freeze-drying box 1 has fixed mouth, and the inwall of fixed mouth is connected with box door 19 by hinge rotation, and one side outer wall of box door 19 is welded with handle 20.

[0028] Wherein, one side outer wall of freeze-drying box 1 is connected with fan 11 by bo...

Embodiment 2

[0031] refer to Figure 4 , a kind of freeze-drying equipment for food processing. Compared with Embodiment 1, this embodiment also includes an observation port on one side of the outer wall of the door 19, and an observation window 21 is connected to the inner wall of the observation port by fastening bolts.

[0032] Working principle: when in use, the freeze-dried state of the food can be directly observed through the observation window 21 on the box door 19, which is more convenient to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com