Preparation method of polyimide nanofiber aerogel with controllable microstructure

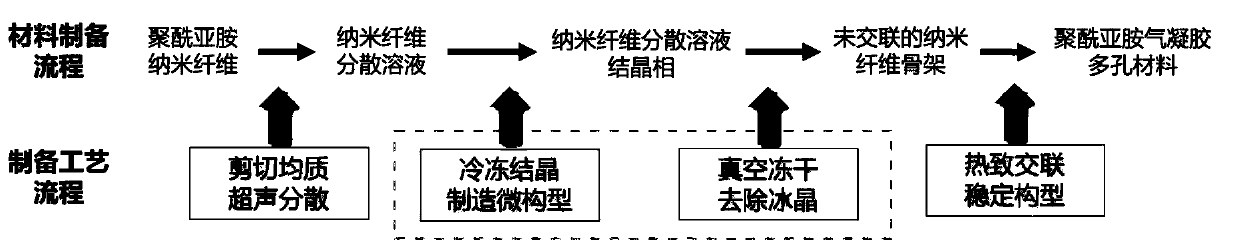

A nanofiber and polyimide technology is applied in the field of preparation of polyimide nanofiber aerogel, which can solve the problems of difficult forming and processing of aerogel, complicated method and process, easy to break, etc., and can overcome low mechanical strength. , Improve the operation efficiency, the effect of the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

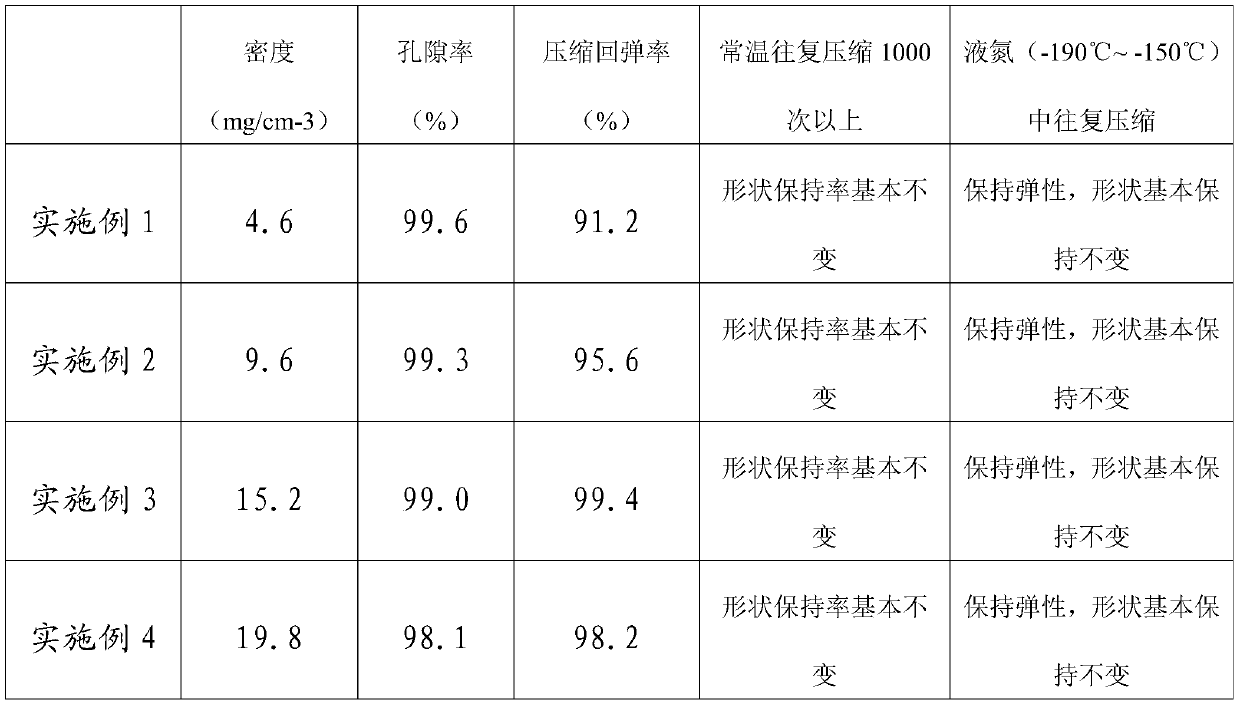

Embodiment 1

[0034] Step 1: After shearing 100 mg of polyimide, place it in 25 ml of solvent for ultrasonic dispersion to obtain a homogeneous nanofiber dispersion solution; the time for the ultrasonic dispersion is 0.5 hours, and the solvent is 1,4-dioxane .

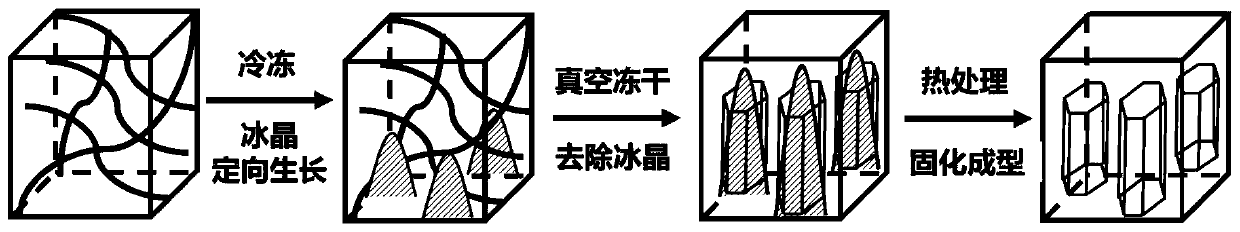

[0035] Step 2: Freezing and crystallizing the nanofiber dispersion solution to produce a microstructure to obtain a crystalline phase of the nanofiber dispersion solution; in the freezing crystallization process, the nanofiber dispersion solution is placed in an environment with a temperature gradient to obtain a temperature gradient Gradient samples are then subjected to freeze crystallization to obtain the crystalline phase of the nanofiber dispersion solution. The temperature range of the temperature gradient is 4°C, the temperature gradient is 2°C / cm, and the time for placing in the temperature gradient environment is 30 minutes; the temperature of the frozen crystallization is -120°C, and the temperature of the frozen crystalli...

Embodiment 2

[0039] Step 1: After shearing 200 mg of polyimide, place it in 25 ml of solvent for ultrasonic dispersion to obtain a homogeneous nanofiber dispersion solution; the time for the ultrasonic dispersion is 3 hours, and the solvent is 1,4-dioxane .

[0040]Step 2: Freezing and crystallizing the nanofiber dispersion solution to produce a microstructure to obtain a crystalline phase of the nanofiber dispersion solution; in the freezing crystallization process, the nanofiber dispersion solution is placed in an environment with a temperature gradient to obtain a temperature gradient Gradient samples are then subjected to freeze crystallization to obtain the crystalline phase of the nanofiber dispersion solution. The temperature range of the temperature gradient is 20°C, the temperature gradient is 2°C / cm, and the time for placing in the environment with a temperature gradient is 1h; the temperature of the frozen crystallization is 10°C, and the time for the frozen crystallization for...

Embodiment 3

[0044] Step 1: After shearing 360 mg of polyimide, place it in 25 ml of solvent for ultrasonic dispersion to obtain a homogeneous nanofiber dispersion solution; the time for the ultrasonic dispersion is 0.5 hours, and the solvent is 1,4-dioxane .

[0045] Step 2: Freezing and crystallizing the nanofiber dispersion solution to produce a microstructure to obtain a crystalline phase of the nanofiber dispersion solution; the freezing crystallization process is the first freeze crystallization of the nanofiber dispersion solution to obtain a frozen sample , and then placing the frozen sample in an environment with a temperature gradient to obtain a temperature gradient sample, and then subjecting the temperature gradient sample to a second freezing crystallization to obtain the crystalline phase of the nanofiber dispersion solution; the second The temperature of the first freezing and crystallization is -120°C, and the time for the first freezing and crystallization is 0.5h; the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com