Thermal-uniformity tray for freeze dryer

A technology of freeze-drying and uniformity, which is used in dryers, drying solid materials without heating, drying, etc., can solve problems such as uneven freeze-drying rate, and achieve improved freeze-drying effect, simple structure and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

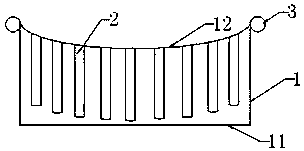

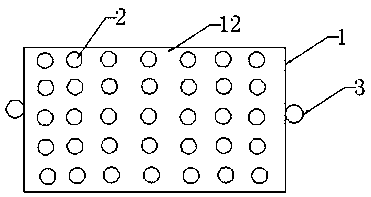

[0020] The invention discloses a thermal uniformity freeze dryer tray, comprising a tray main body 1, the tray main body 1 is a solid rectangular structure, the bottom surface 11 of which is in contact with the freeze dryer partition is flat, and its top surface 12 is concave Surface; the tray main body 1 is drilled with a number of evenly distributed slots 2, the bottom of the slots 2 is a blind hole, and the top of the slot is an open structure. The height of each slot 2 is the same, and its height is less than the height of the vial (for holding the article to be freeze-dried), so that the vial can be taken and placed; its inner wall is in contact with the outer wall of the vial, so that the direct heat transfer is the vial. bottle.

[0021] The vertical distance between the blind hole end of the slot 2 and the bottom surface of the tray main body 1 gradually increases from the middle of the tray main body 1 to its four sides. Specifically, the shape of the surface formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com