One-stage dynamic freeze-drying method of freeze-dried mask

A technology of freeze-drying and facial mask, which is applied in drying, pharmaceutical formulations, drying solid materials, etc. It can solve the problems of easy collapse and drying of products, long drying process, and incomplete drying, so as to achieve high freeze-drying treatment effect and increase the degree of supercooling , The effect of improving the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

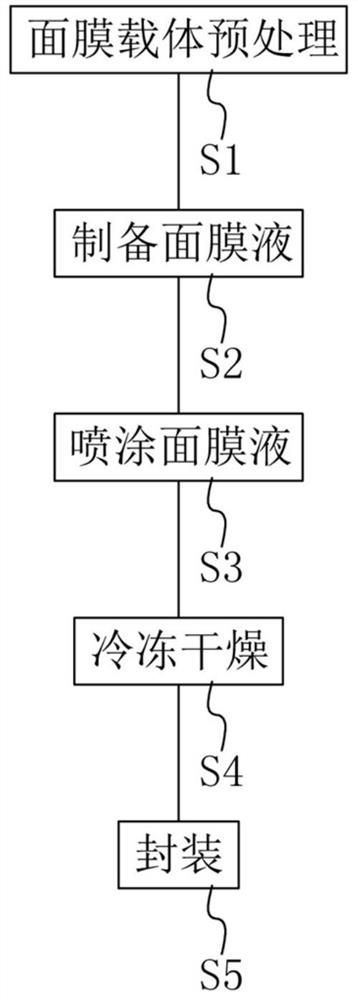

[0024]A one-step dynamic freeze-drying method of freeze-dried facial mask, such asfigure 1 As shown, including the following steps:

[0025]S1. Pretreatment of the mask carrier: use a dryer to dry the mask carrier; the power of the dryer is 60 kilowatts, and use the dryer to dry the mask carrier for 100 minutes;

[0026]S2. Preparation of facial mask liquid: stir and mix the ingredients of the facial mask liquid evenly to make a facial mask liquid; the raw materials of the facial mask liquid include polysaccharides, ceramides, polymer moisturizing ingredients, collagen and active extracts; in the facial mask liquid, based on The total weight of the facial mask liquid includes: 6 parts of polysaccharides, 1 part of ceramides, 3 parts of high molecular moisturizing ingredients, 10 parts of collagen, and 60 parts of extracts;

[0027]S3. Spraying mask liquid: spray the mask liquid on the mask carrier several times;

[0028]S4. Freeze drying: The freezing tunnel uses liquid nitrogen for freezing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com