Novel medicinal bottle stopper for lyophilized powder formulation

A technology for freeze-drying bottle stoppers and bottle stoppers, which is applied in the field of bottle caps, can solve the problem of not being able to meet the freeze-drying effect of freeze-dried powder injection, and achieve the effects of simple structure, high machine efficiency and convenient use.

Inactive Publication Date: 2009-04-22

应城市恒天药业包装有限公司

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

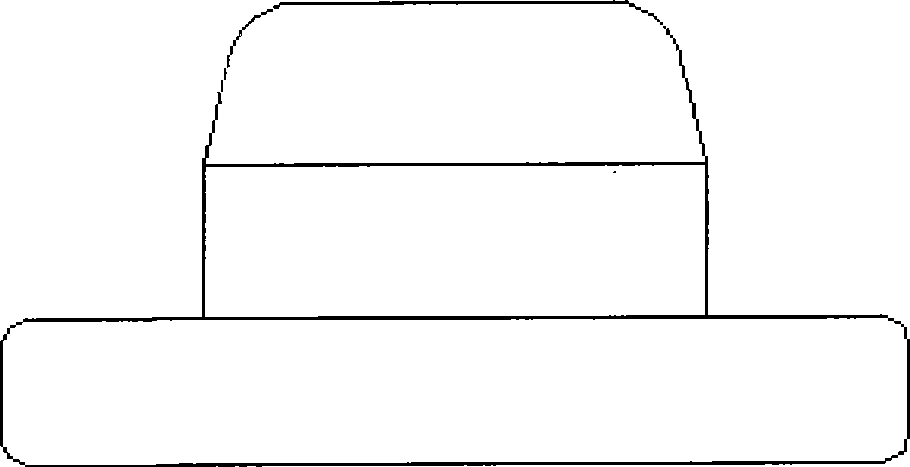

Existing medicinal bottle cap structure is relatively simple, as figure 1 The structure shown is generally a common one-time molding structure, which has the advantages of good airtightness, but it cannot meet the conditions of good freeze-drying effect and vacuum rapid aseptic packaging required for the production of freeze-dried powder injections

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

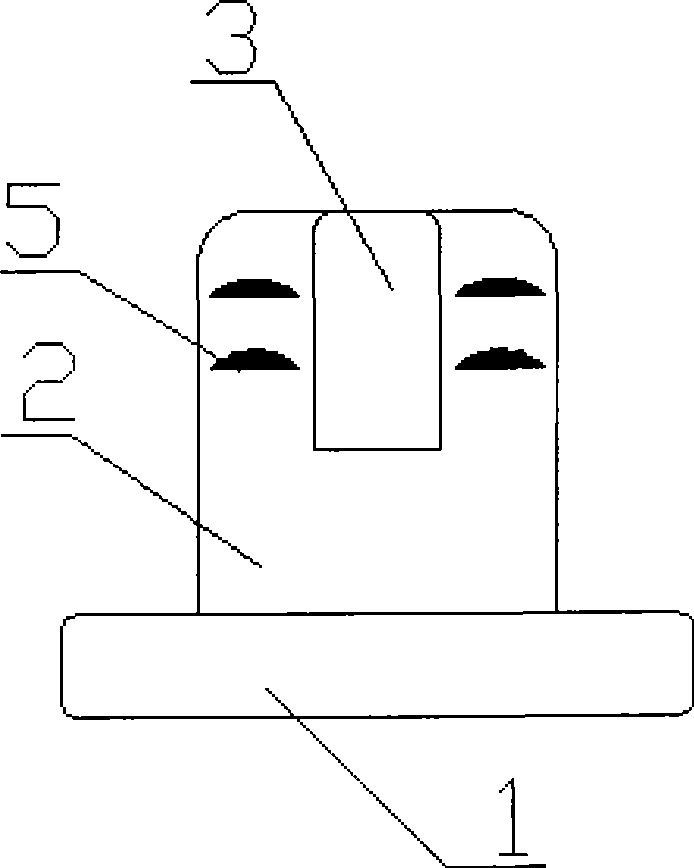

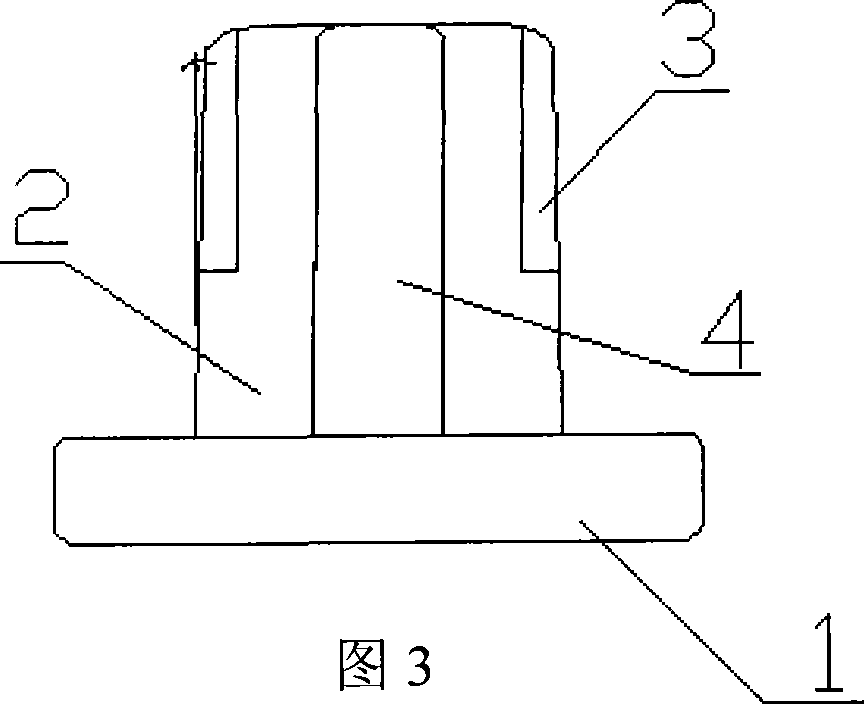

[0013] Such as figure 2 , shown in Fig. 3, the present invention comprises bottle cap 1 and bottle stopper 2, and the periphery of bottle stopper 2 is evenly opened with four circular ventilation grooves 3. Such as Figure 4 As shown, the center of the cork has a circular hole

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a bottle cap, in particular to a novel medical freeze-dried bottle stopper, which comprises a bottle stopper of which a center is provided with a round hole, and is characterized in that the periphery of the bottle stopper is uniformly provided with four round vent grooves, an outer wall of the bottle stopper is provided with double wedges, and a neck of the bottle stopper is provided with a 3 DEG guide angle. The novel medical freeze-dried bottle stopper has the advantages of simple structure and convenient use, can ensure that a packaging bottle has good air tightness, has the advantages of good freeze-drying effect and high production efficiency during production and packaging processes of freeze-dried powder injection, is favorable for the quick vacuum aseptic packaging of medicines, and improves the quality of products and the efficiency.

Description

technical field [0001] The invention relates to a bottle cap, in particular to a novel medicinal freeze-dried bottle stopper. Background technique [0002] Existing injections and powder medicines are generally bottled, and especially freeze-dried powder injections are generally bottled according to national pharmaceutical product standards, and sealed with rubber caps for preservation. The production of freeze-dried powder injections is generally to freeze-dry the medicinal liquid containing the active ingredients of the drug and carry out vacuum aseptic packaging, and the production process is generally very long. For example, the production process of a certain product is as follows: first cool down for 2 hours, the temperature drops to -40°C, and maintain this temperature for about 6 hours; start to gradually increase the temperature to 25°C, a vacuum state is required during this process, and it takes about 30-35Pa to maintain a vacuum. It takes about 48 hours; the fre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A61J1/00

Inventor 石雄安夏汉桥丁安华

Owner 应城市恒天药业包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com