Method for brazing Ti2AlC ceramics and Cu with Cu-Sn-Ti solder

A technology of cu-sn-ti and solder, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., to achieve high strength, good electrical conductivity, and good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

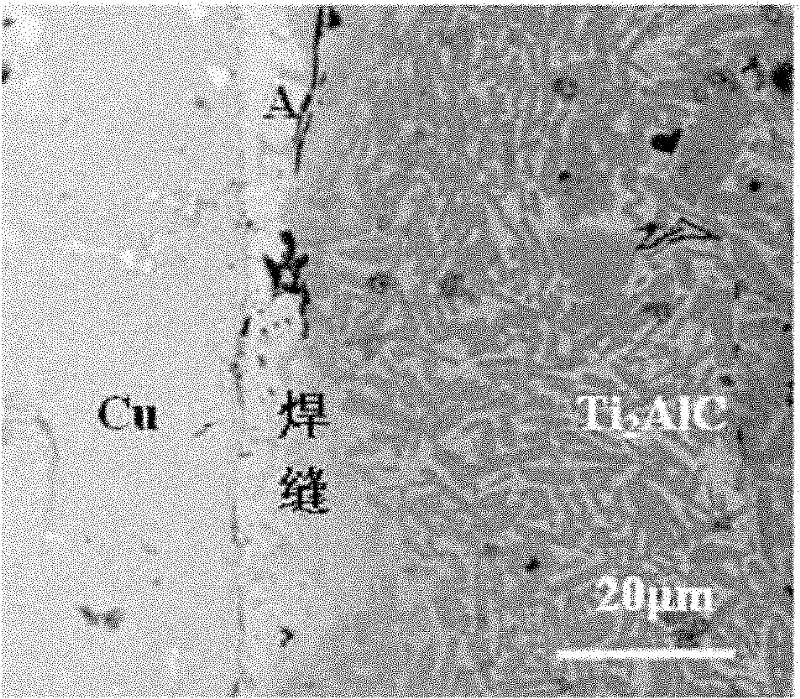

[0018] The Cu—Sn—Ti solder in this embodiment is powder solder, which can ensure the electrical conductivity of the joint. Cu-Sn-Ti solder is Cu-based solder, and since one side of the base material is pure copper, a certain amount of Sn is added to the solder to lower the melting point. However, considering that the Cu element in the solder will interact with Ti 2 There is a strong interaction between the AlC ceramic base material, so a certain amount of Ti is added to the solder, because Ti and Cu can form a variety of reactants, thereby reducing the amount of Cu and Ti. 2 The interaction of AlC ceramic base material, in addition, the addition of Ti element is beneficial to improve the wettability of Cu-Sn-Ti solder.

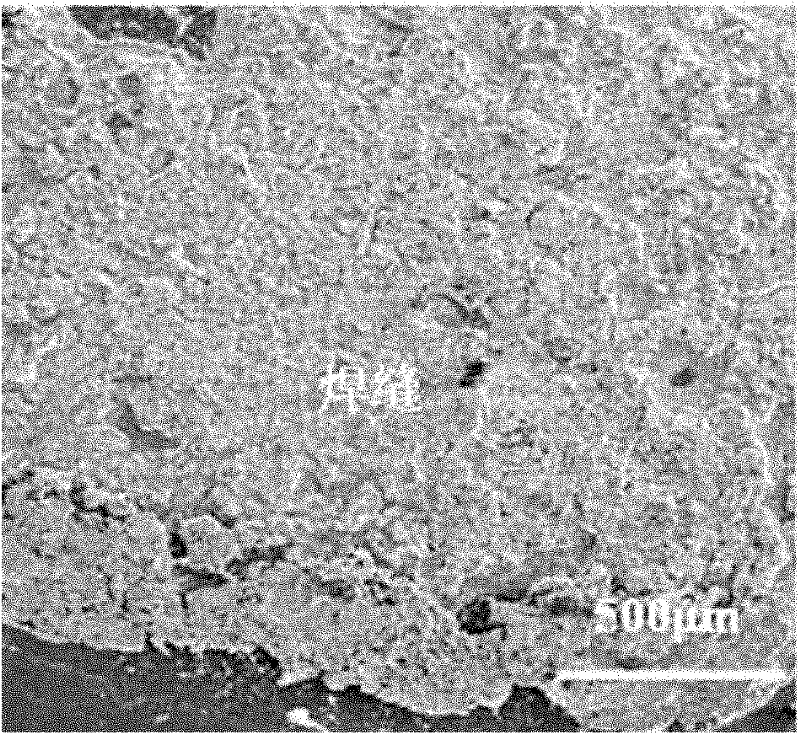

[0019] The Cu-Sn-Ti brazing filler metal of this embodiment brazes Ti 2 The compressive shear strength of the joint obtained by AlC ceramics and copper reaches 40.53-187MPa, and the electrical conductivity reaches 5.130×10 6 ~5.997×10 6 S / m.

[0020] Spec...

specific Embodiment approach 2

[0022] Specific embodiment three: the use of Cu-Sn-Ti solder brazing Ti in this embodiment 2 The method of AlC ceramics and copper is realized through the following steps: one, the Ti 2 AlC ceramics were polished to a bright surface with 320#, 600#, 800#, 1000#, 1200# and 1600# metallographic sandpaper in sequence, and then Ti 2 The surface to be connected of AlC ceramics is polished; then the copper is polished to a bright surface with 1000# and 1600# metallographic sandpaper successively, and then the diamond polishing agent of 0.5 μm is used to polish the surface to be connected of the copper; 2. After step 1 Treated Ti 2 Immerse AlC ceramics and copper in absolute ethanol, ultrasonically clean them for 10-20 minutes, take them out, and dry them in the air; 3. Mix Cu-Sn-Ti solder and hydroxyethyl cellulose binder to obtain paste-like Cu-Sn-Ti solder material, and then paste Cu-Sn-Ti solder, Ti 2 Assembly of AlC ceramic and copper into Ti 2 AlC ceramics / Cu-Sn-Ti solder / c...

specific Embodiment approach 3

[0024] The Cu-Sn-Ti brazing filler metal of this embodiment brazes Ti 2 The method of AlC ceramics and Cu controls the brazing temperature (920-980°C) and holding time (10-30min) to control the thickness of the reaction layer and the distribution of the reaction phase in the joint, thereby achieving the purpose of controlling the structure and performance of the joint. successfully achieved Ti 2 The connection between AlC ceramics and Cu, and a joint with high strength and good conductivity is obtained. The compressive shear strength of the joint reaches 40.53-187MPa, and the electrical conductivity reaches 5.130×10 6 ~5.997×10 6 S / m.

[0025] Ti in this embodiment 2 The successful joining of AlC ceramics and Cu, the Ti 2 The connectors of AlC ceramics and Cu are used in current-carrying friction devices, which can solve the problems of high cost and short life of current-carrying friction devices in existing engineering applications, and have an inestimable role in the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com