Method for preparing ternary ethylene propylene vulcanized rubber powder master batches, products and application

A technology of ethylene propylene vulcanizate and EPDM, which is applied in the chemical industry to achieve the effects of avoiding excessive processing, improving the ratio of performance to cost, and improving the degree of dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, special glue for flooring in the car

[0025] (1-1), preparation of EPDM vulcanized rubber powder masterbatch:

[0026] Get 100 parts by weight of 60 mesh EPDM vulcanized rubber powder,

[0027] 50 parts by weight of softening agent (paraffin oil);

[0028] Mix the above-mentioned materials with a high-speed mixer for 5 minutes, cool down and bag them after leaving the machine, and store them for a day and night for later use.

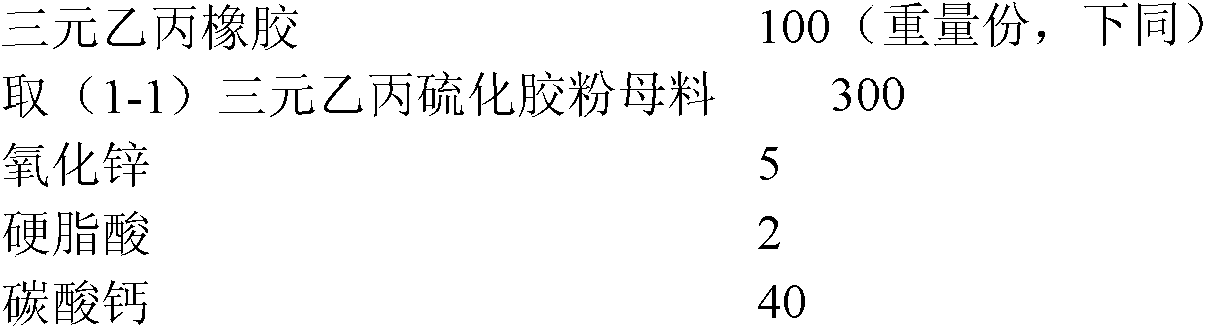

[0029] (1-2) For the special material for flooring in the car, the specific formula of the rubber material is:

[0030]

[0031]

[0032] The formula rubber is mixed according to the conventional process, such as: first add raw rubber, then add zinc oxide, stearic acid, processing aids, then add carbon black, calcium carbonate, rubber powder masterbatch, and finally add vulcanizing agent and accelerator, No off-roll phenomenon;

[0033] (1-3) The conclusion of the test on the rubber material: the hardness and other indica...

Embodiment 2

[0034] Embodiment 2, other ethylene-propylene rubber floor special glue

[0035] (2-1), preparation of EPDM vulcanized rubber powder masterbatch:

[0036] Get 100 parts by weight of 60 mesh EPDM vulcanized rubber powder,

[0037] 100 parts by weight of softening agent (machine oil);

[0038] Vulcanization system materials (containing sulfur, BZ, CZ, TMTD) 5 parts by weight

[0039] Mix the above-mentioned materials with a high-speed mixer for 5 minutes, pack them into 20kg bags after leaving the machine, and store them for a day and night for later use.

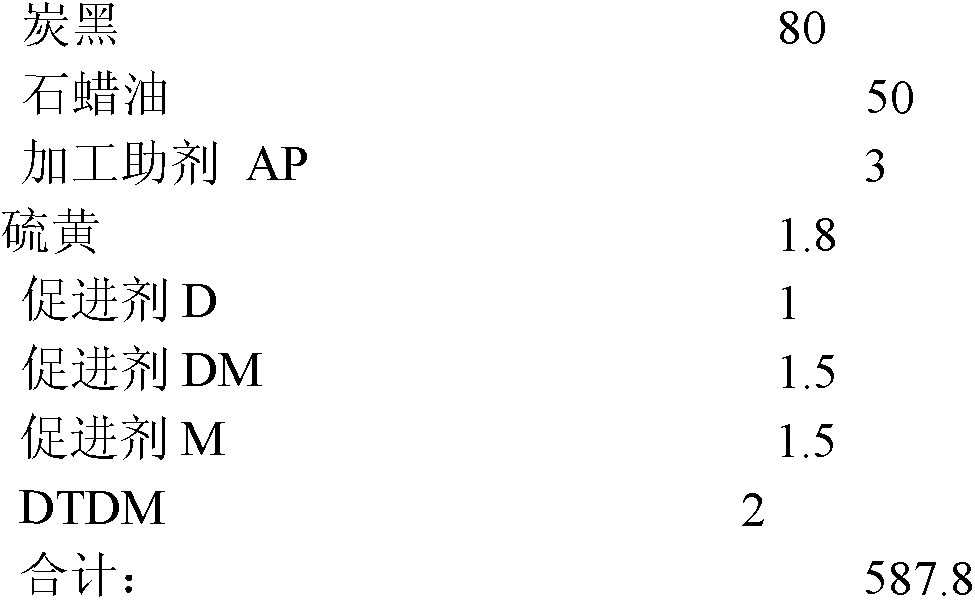

[0040] (2-2) For other special materials for ethylene-propylene rubber flooring, the specific formula of the rubber material is:

[0041]

[0042] The formula rubber is mixed according to the conventional process, such as: put raw rubber first, then add zinc oxide, stearic acid, processing aids, then add carbon black, rubber powder masterbatch, and finally add vulcanizing agent and accelerator, no off-roll Phenomenon; ...

Embodiment 3

[0044] Embodiment 3, adding EPDM vulcanized rubber powder masterbatch in the shock absorber

[0045] (3-1), preparation of EPDM vulcanized rubber powder masterbatch:

[0046] Get 100 parts by weight of 60 mesh EPDM vulcanized rubber powder,

[0047] 10 parts by weight of softening agent (naphthenic oil);

[0048] Mix the above-mentioned materials with a high-speed mixer for 5 minutes, cool down and bag them after leaving the machine, and store them for a day and night for later use.

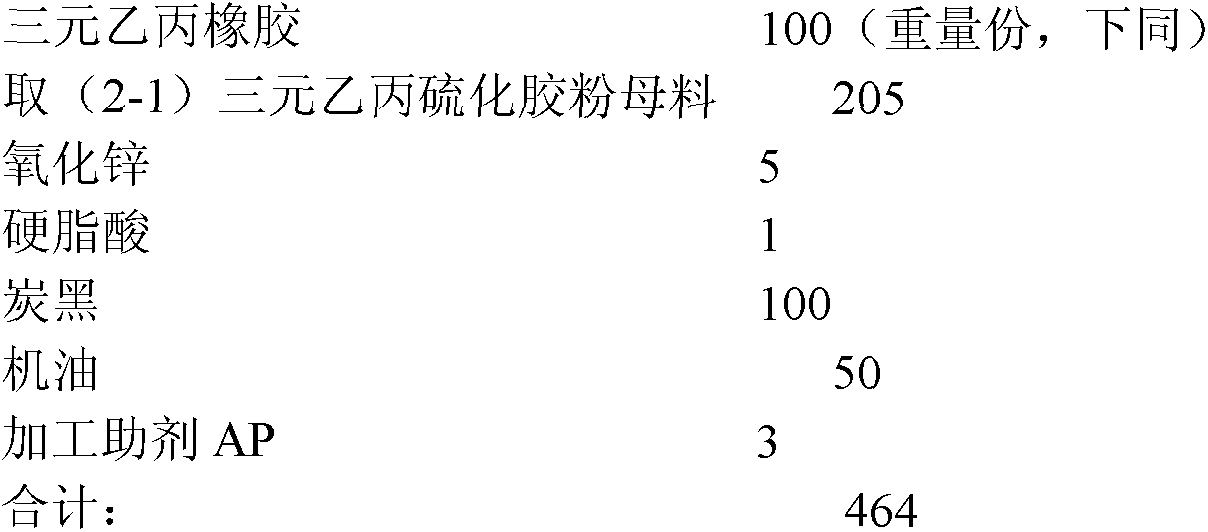

[0049] (3-2) Special material for ethylene-propylene rubber shock-absorbing parts, the specific formula of the rubber material is:

[0050]

[0051]

[0052] The formula rubber is mixed according to the conventional process, such as: first add raw rubber, then add zinc oxide, stearic acid, processing aids, then add carbon black, rubber powder masterbatch, and finally add vulcanizing agent and auxiliary crosslinking agent ;

[0053] (3-3) Test conclusions on rubber materials: before and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com