Preparation method of dye sensitized nano film solar cell electrode

A technology for solar cells and nano-films, which is applied in circuits, electrical components, and final product manufacturing, etc., can solve the problems that hinder the wide application of solar cells and have not been significantly improved, and achieve simple and easy technology, reduce production costs, and improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

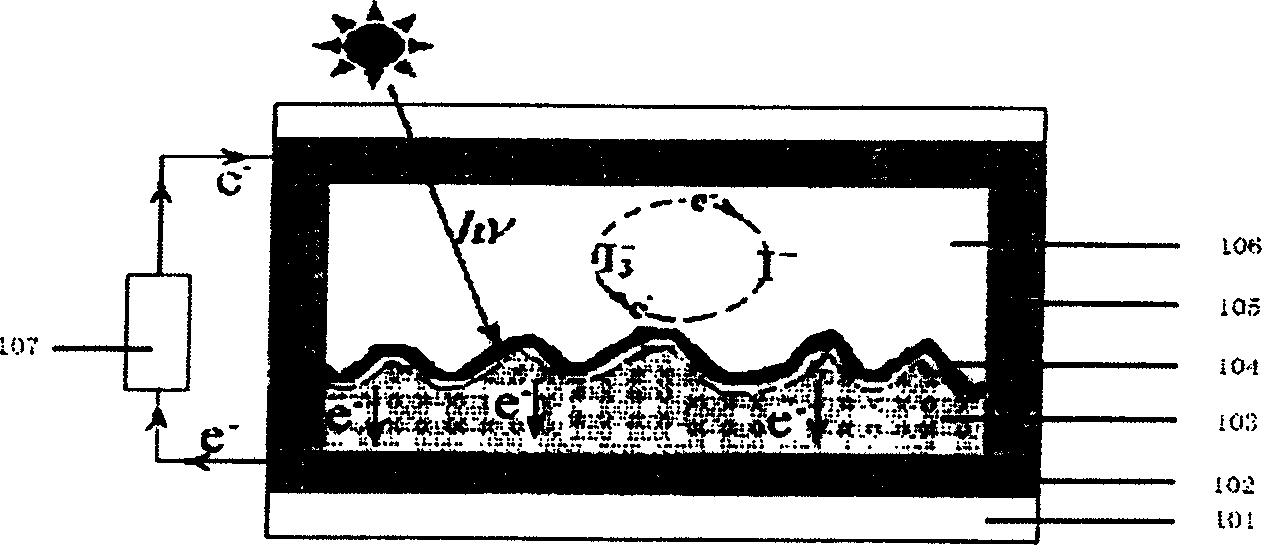

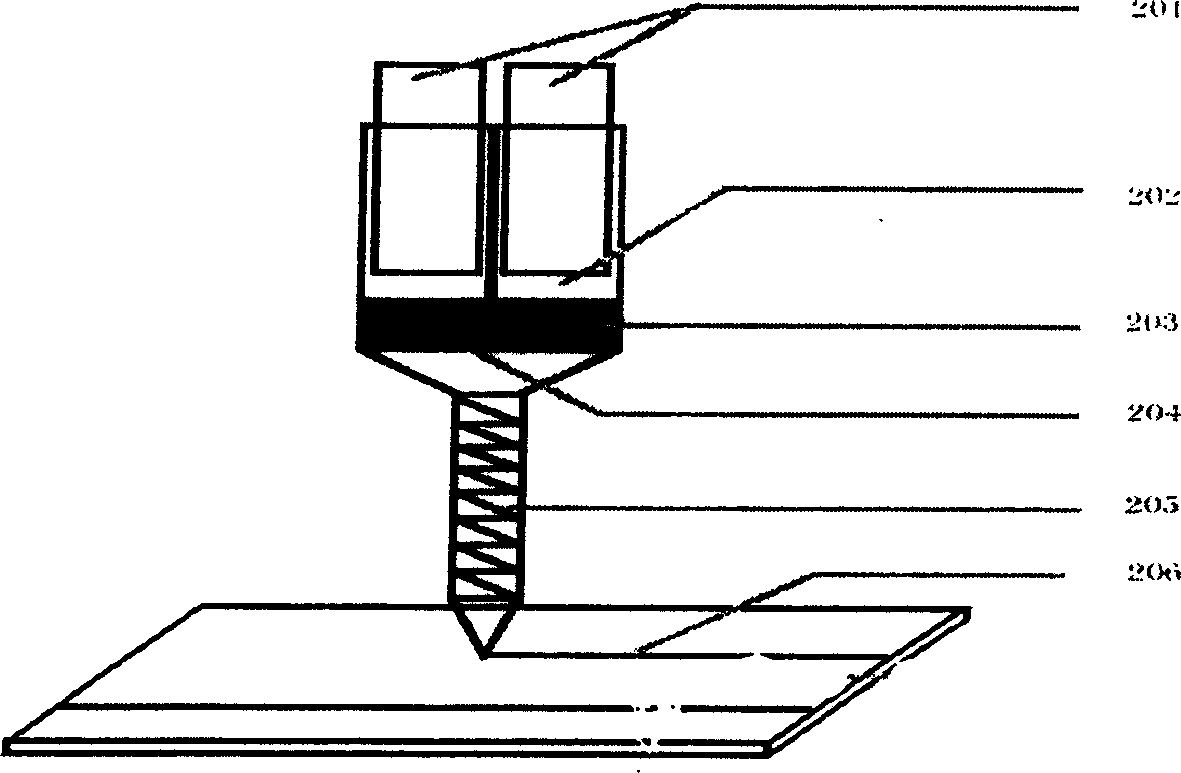

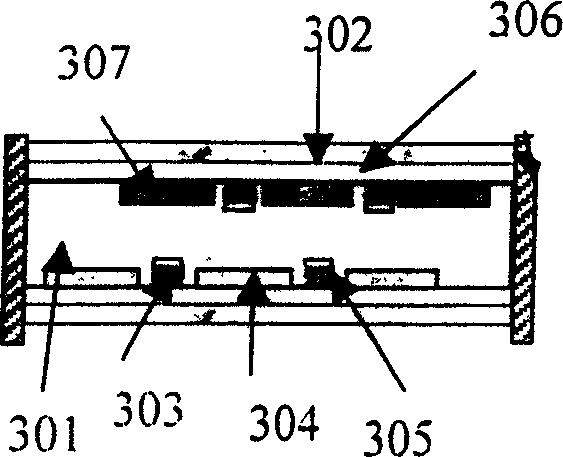

[0024] see figure 1 , figure 2 , image 3 . 101—glass 102—conductive film 103—porous semiconductor film 104—organic dye adsorption layer 105—sealing material 106—electrolyte 107—load, 201—cylinder 202—multi-cylinder extruded tube 203—mixture of metal powder and binder 204—adhesive 205—special mixer 206—two-dimensional platform, 301—electrolyte 302—conductive glass 303—metal electrode 304—catalyst 305—electrode protection layer 306—conductive film 307—titanium dioxide film.

[0025] Place the conductive glass baked to a certain temperature on the two-dimensional platform 206;

[0026] Select 50-400 mesh tungsten powder and epoxy resin to make a mixed slurry, and put the mixed slurry and phenolic resin into the multi-barrel extrusion tube 202 respectively;

[0027] Adjust the cylinder pressure so that the mixed slurry for preparing the electrode can be mixed by a special mixer 205 and squeezed out evenly according to a certain ratio;

[0028] Make the conductive glass 302 ...

Embodiment 2

[0031] see Figure 4 , in the figure, 401—conductive glass 402—conductive film 403—metal electrode 404—titanium dioxide film 405—electrolyte 406—conductive glass 407—sealing layer 408—oxidant

[0032] 1. Place the conductive glass 401 for which electrodes are to be prepared on the printing platform 206 .

[0033] 2. Center the designed screen and put the prepared silver / palladium slurry, that is, the mixed slurry of silver / palladium powder, glass powder and terpineol.

[0034] 3. Printing, coating the silver / palladium paste on the conductive glass 401 .

[0035] 4. Paste the conductive glass 401 and the conductive glass 406 together.

[0036] 5. Sinter in a tunnel kiln between 50 and 700 °C.

[0037] 6. It is also possible to cover a layer of acrylic resin polymer adhesive on the sintered conductive glass 401 with a flat press machine to form a protective layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com