Bender transducer for generating electrical energy from mechanical deformations

A mechanical deformation, transducer technology, applied in the direction of generator/motor, piezoelectric device/electrostrictive device, piezoelectric/electrostrictive/magnetostrictive device, etc., to improve stability, improve reliability, The effect of simple and reliable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

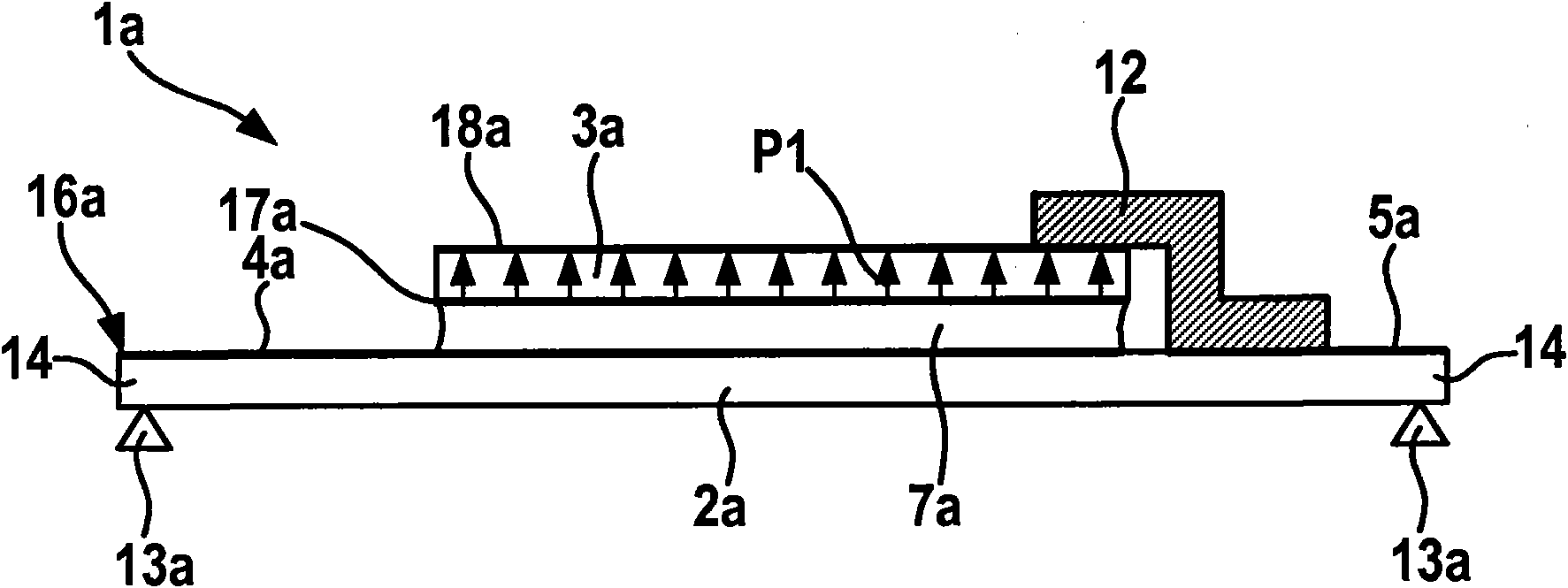

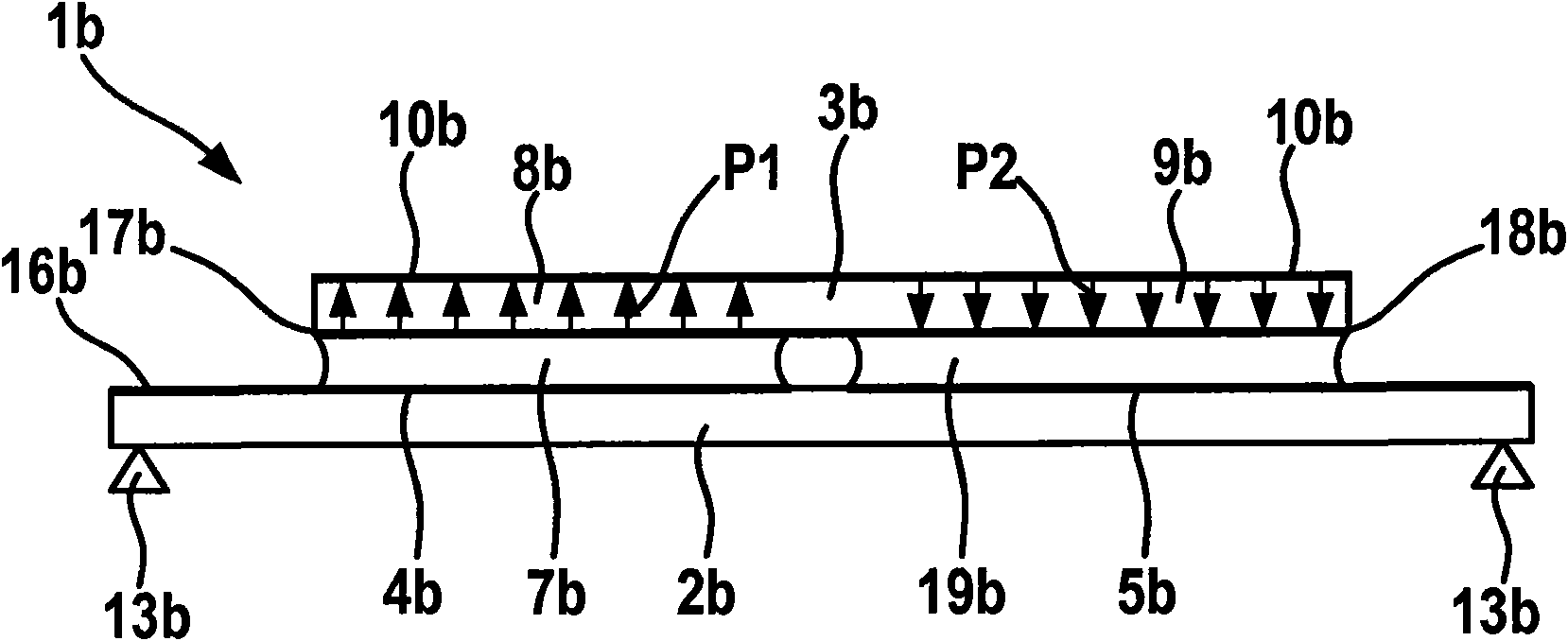

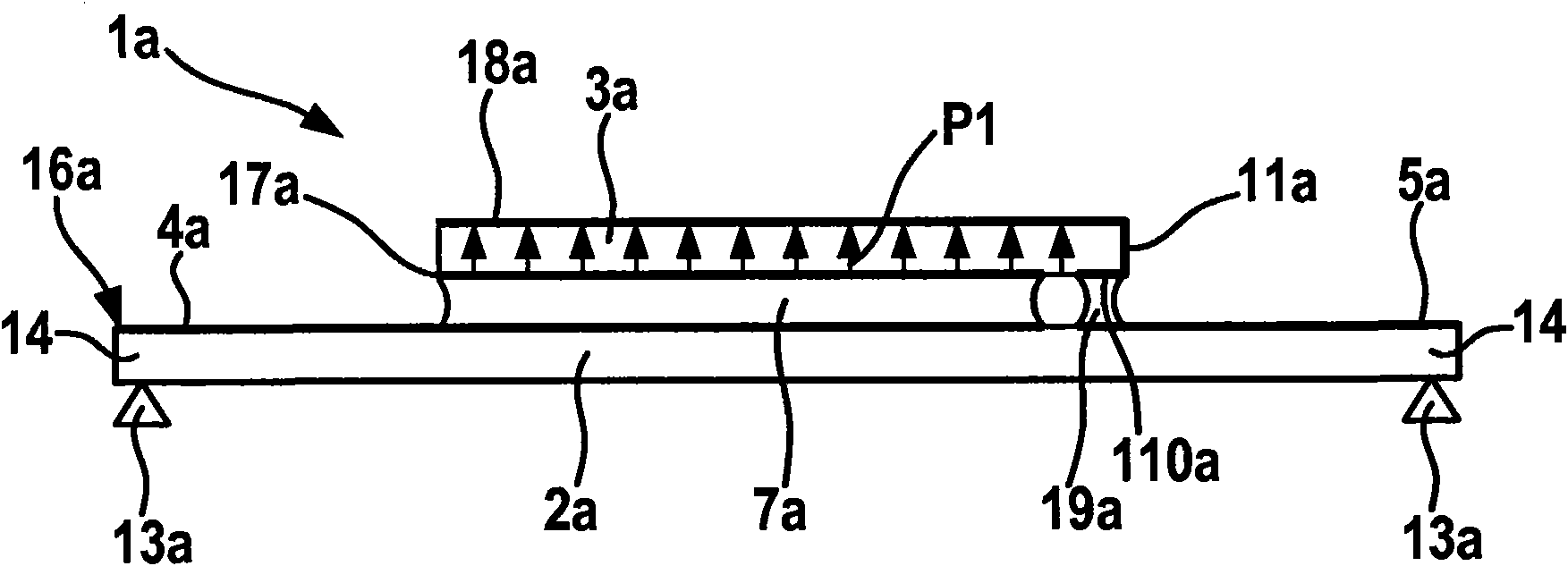

[0026] one in figure 1 The bending transducer 1a shown in includes a deformable carrier 2a and a piezoelectric element 3a. The carrier 2a has a planar and plane-parallel shape and is elastically deformable; here, the carrier is supported or clamped on the support elements 13a with its two opposite side regions 14, so that Deformation between, especially bending deformation. The first connecting electrode 4 a and the second connecting electrode 5 a are applied as part of a structured, electrically conductive layer, in particular a metal layer, on the upper side 16 a of the carrier 2 a by means of a photolithographic process or an etching process, and along the lateral, side Extend outward in the direction.

[0027] The piezo element 3 a is also planar; it is made in particular of a ceramic material and has a consistent polarity direction P1 in this embodiment. The piezoelectric element has a first lower electrode 17a on its lower side serving as a connection side and a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com