A shaft sealing structure of a steam compressor in a vacuum concentration device

A steam compressor and vacuum concentration technology, which is applied to the sealing of the engine, mechanical equipment, engine components, etc., can solve problems such as adverse effects on heat transfer performance, and achieve the effect that the heat transfer performance will not deteriorate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the present invention will be described in detail based on embodiments. In addition, this invention is not limited to the following embodiment.

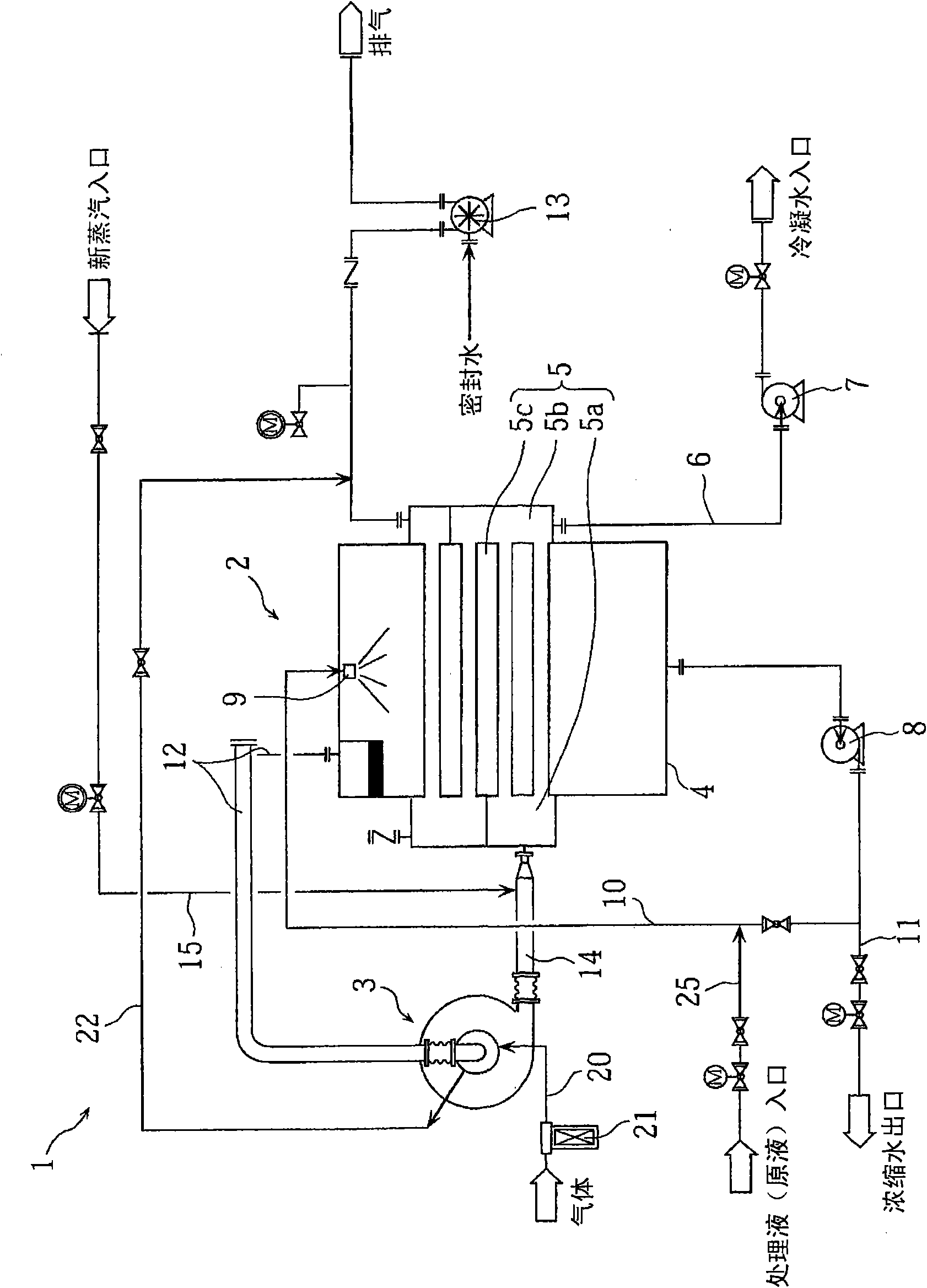

[0028] figure 1 It is an overall configuration diagram of a vacuum concentration facility equipped with a vapor compressor according to an embodiment. The vacuum concentrator 1 is provided with a horizontal tube evaporator 2 for evaporating the supplied treatment liquid, and a steam compressor 3 for adiabatically compressing and generating fresh steam, and is configured to use the steam compressor 3 to increase the temperature and pressure The steam returns to the horizontal tube evaporator 2 as a heat source for evaporating the treatment liquid.

[0029] The horizontal tube evaporator 2 includes an evaporation tank 4 formed in a cylindrical shape and capable of storing a treatment liquid inside. A heater 5 composed of a pair of left and right headers 5a, 5b and a plurality of horizontal heat transfer tubes 5c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com