Leak-proof compression bar type temperature control valve

A temperature control valve, pressure rod technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of valve stem and seal wear and leakage, and achieve the effect of solving leakage and avoiding mechanical friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

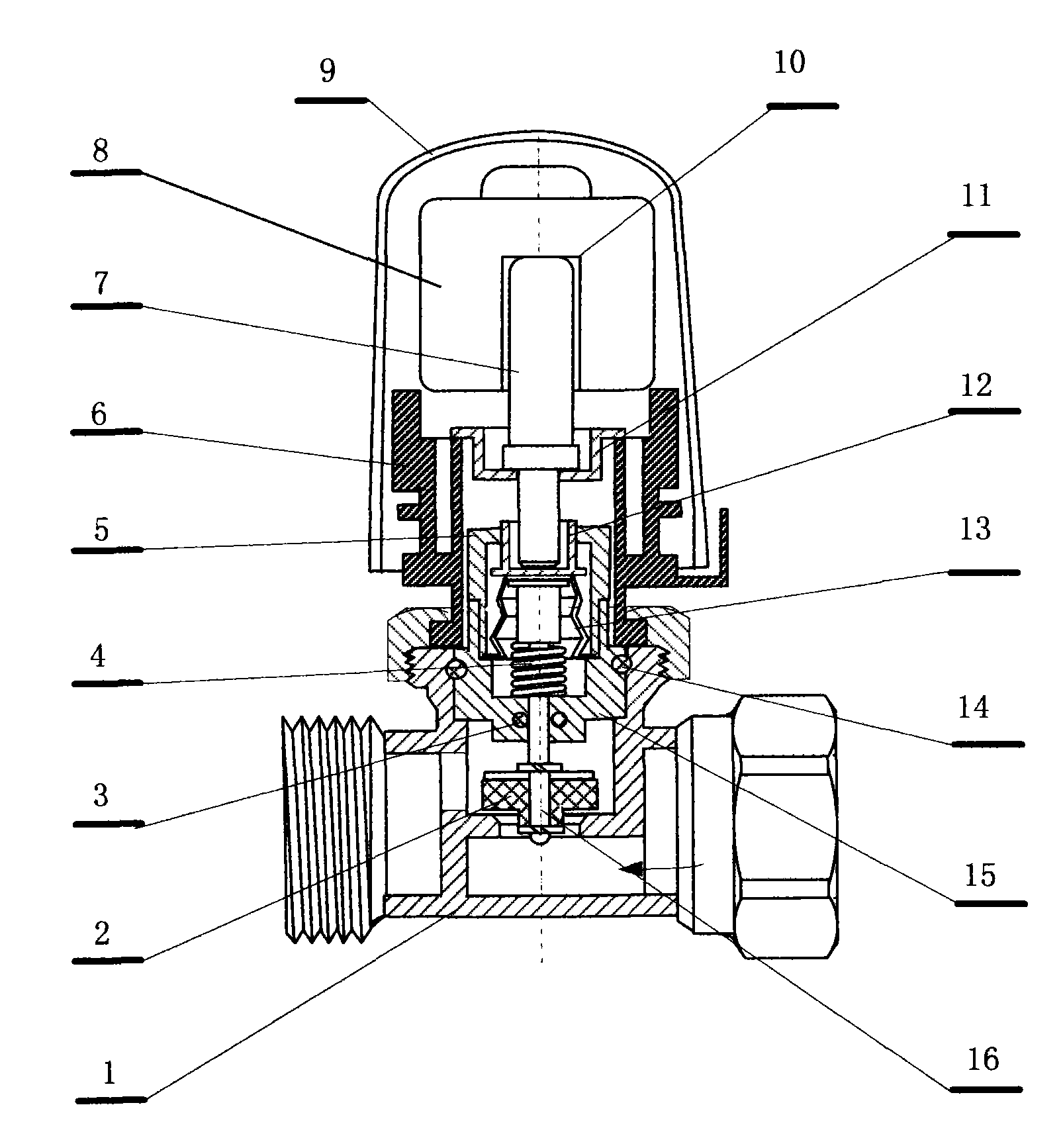

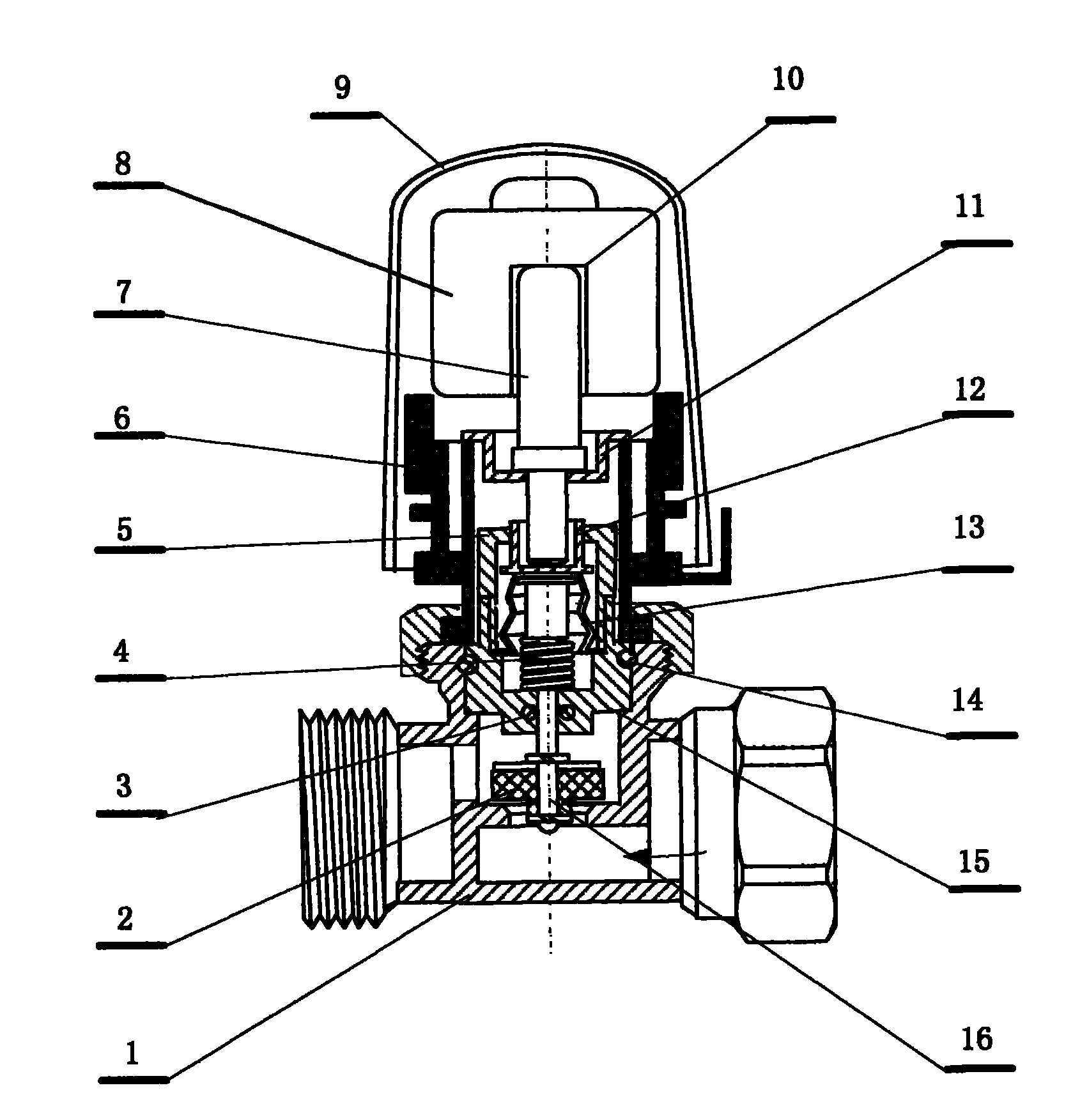

[0008] The specific embodiment of the present invention sees accompanying drawing. The structure mainly includes valve body (1), piston assembly (2), lower sealing ring (3), return spring (4), valve cover (5), bonnet frame (6), linkage assembly (7), temperature bulb (8), bonnet (9), temperature bulb bellows (10), positioning sleeve (11), linkage sleeve (12), sealing bellows (13), upper seal (14), valve sleeve (15), Valve pressure rod (16); the water outlet in the valve body (1) cooperates with the piston assembly (2) to achieve the purpose of opening or closing the valve; the upper step of the valve pressure rod (16) withstands the inner seal bellows (13) The upper end and the middle part are covered with a return spring (4), and the lower part is connected with the piston assembly (2) through the lower sealing ring (3) through the valve sleeve (15); the outer edge of the lower part of the sealing bellows (13) is covered by the valve cover (5 ) is pressed and sealed on the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com