Apparatus and method for mounting FPD board

A technology of FPD board and installation device, which is applied to identification devices, optics, instruments, etc., can solve the problems of increased usage of cleaning tapes, dust removed from the front side re-attaching to the back side, glass sheets scratching the back side, etc., to avoid problems such as The effect of reducing the installation yield and avoiding the increase in the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, use Figure 1 to Figure 4 One embodiment of the present invention will be described.

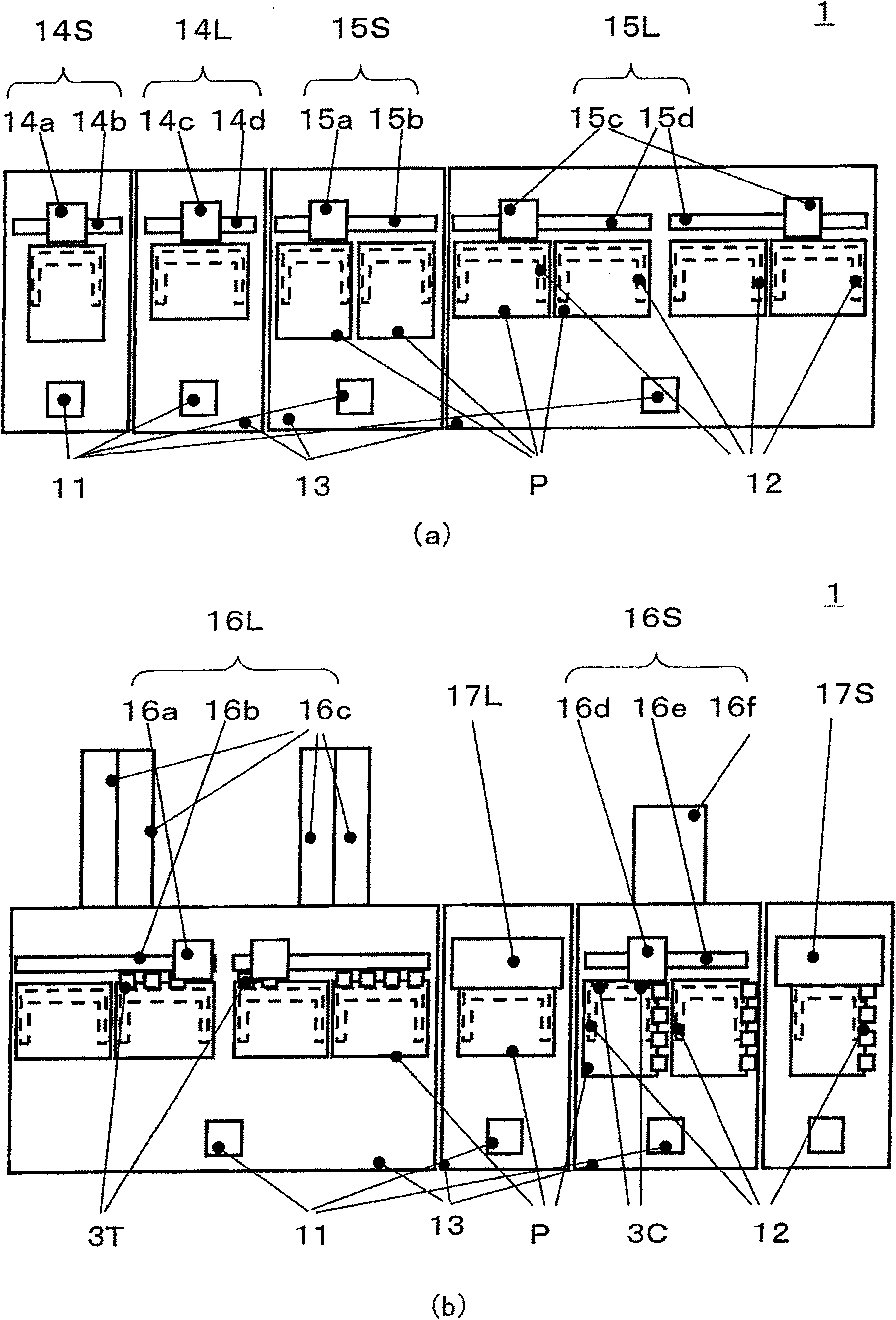

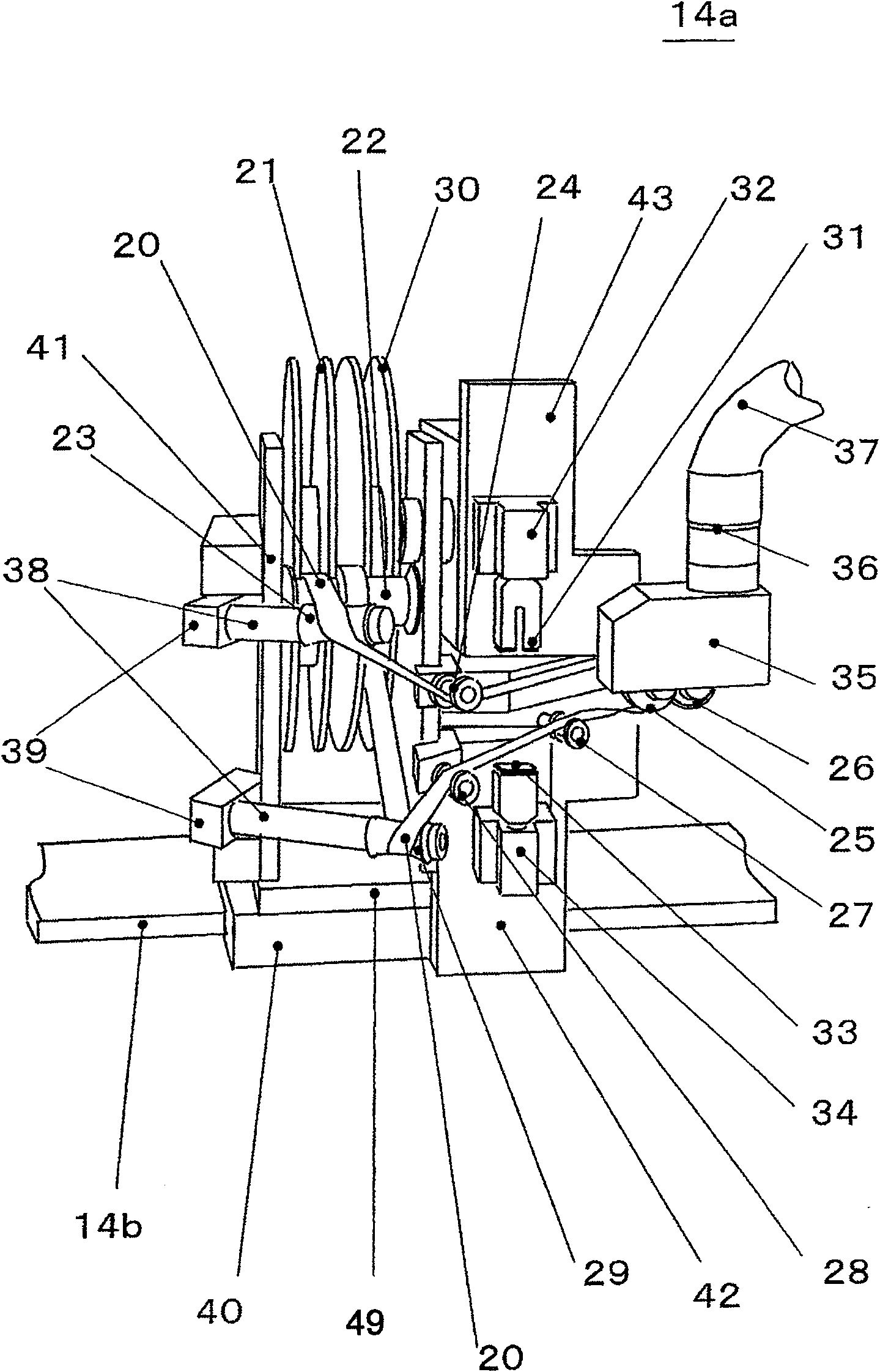

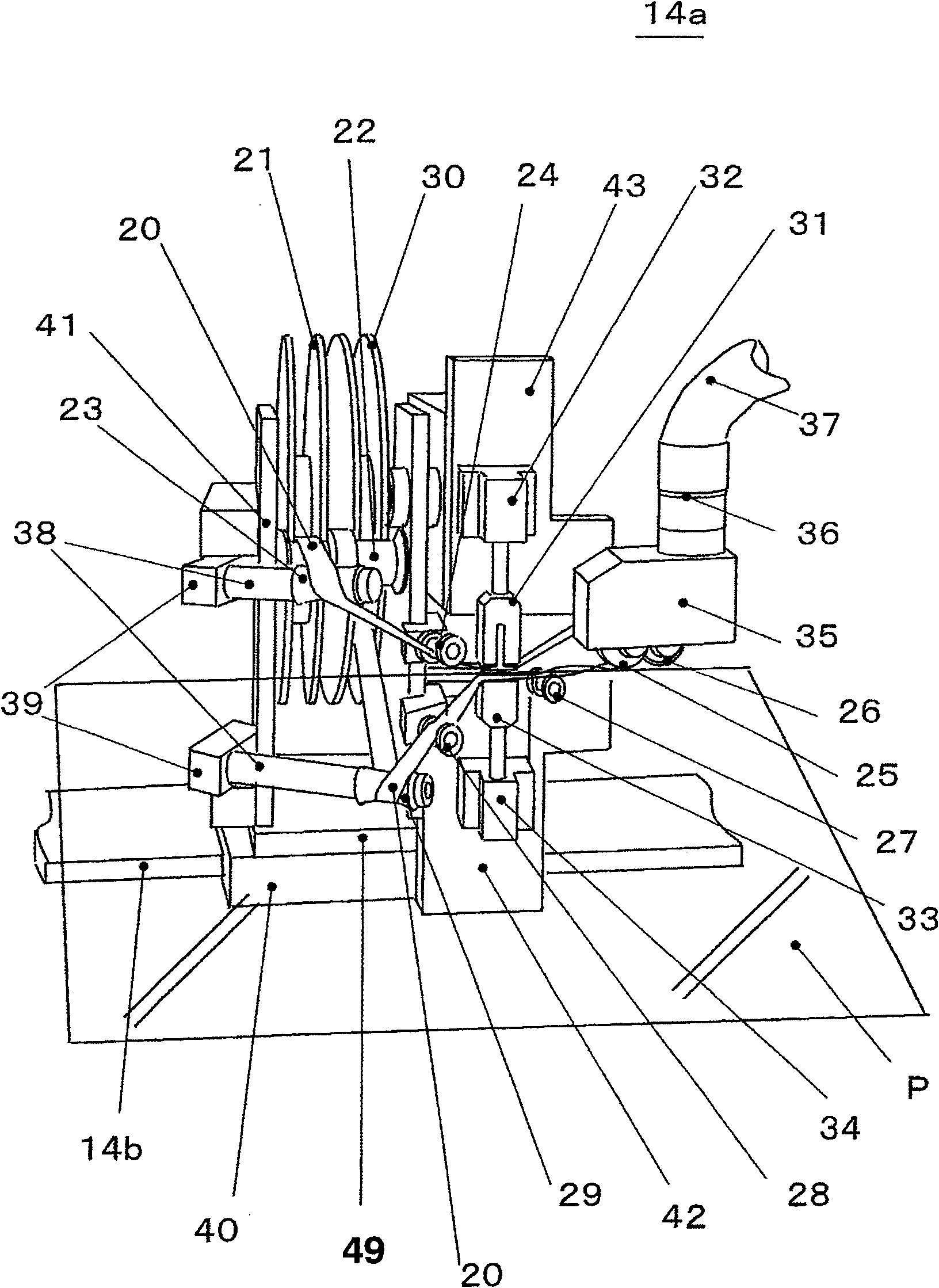

[0025] figure 1 It is a floor layout diagram showing the whole display substrate module assembly line 1 according to the embodiment of the present invention, figure 2 It is a perspective view which shows the appearance of the terminal cleaning head which concerns on 1st Embodiment of this invention.

[0026] figure 1 The device is a conveying device composed of a substrate holding mechanism 12 for holding a substrate P and a conveying arm 11 for conveying the substrate to an adjacent mounting device position. While conveying the substrates sequentially from left to right in the figure, the substrate A mounting line device that performs various processing operations on the peripheral part of the IC and TAB, etc., for mounting and assembly operations, figure 1 (a) means the first half, figure 1 (b) shows the second half. It is actually the connecting installation line, but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com