Lead frame for carrying out ceramic double in-line package (CDIP) on chips

A dual-in-line package and lead frame technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of prolonging the packaging cycle, increasing the production cost, and bonding contact pads, etc., so as to prolong the packaging cycle and increase the High production cost and the effect of saving the number of pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

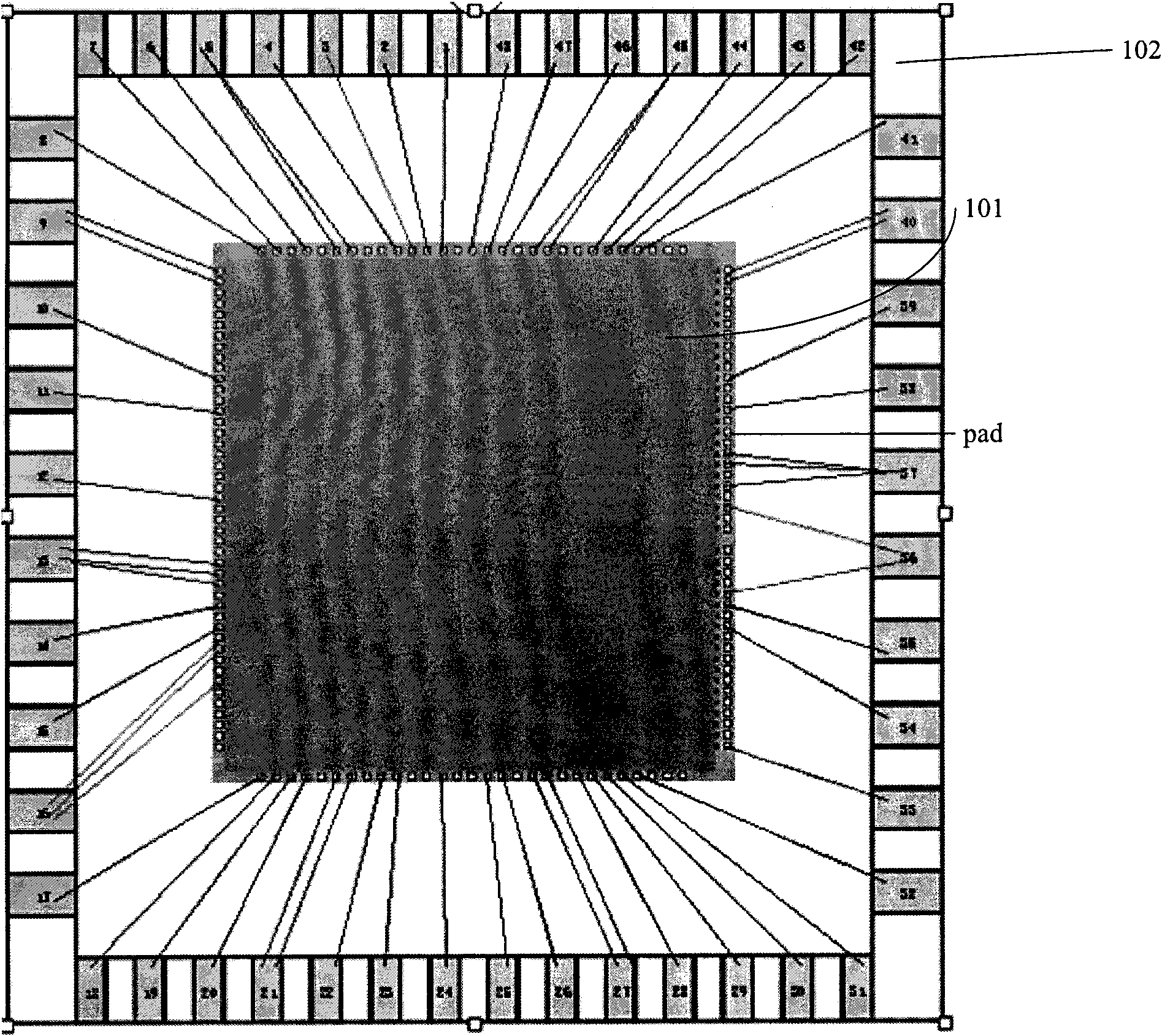

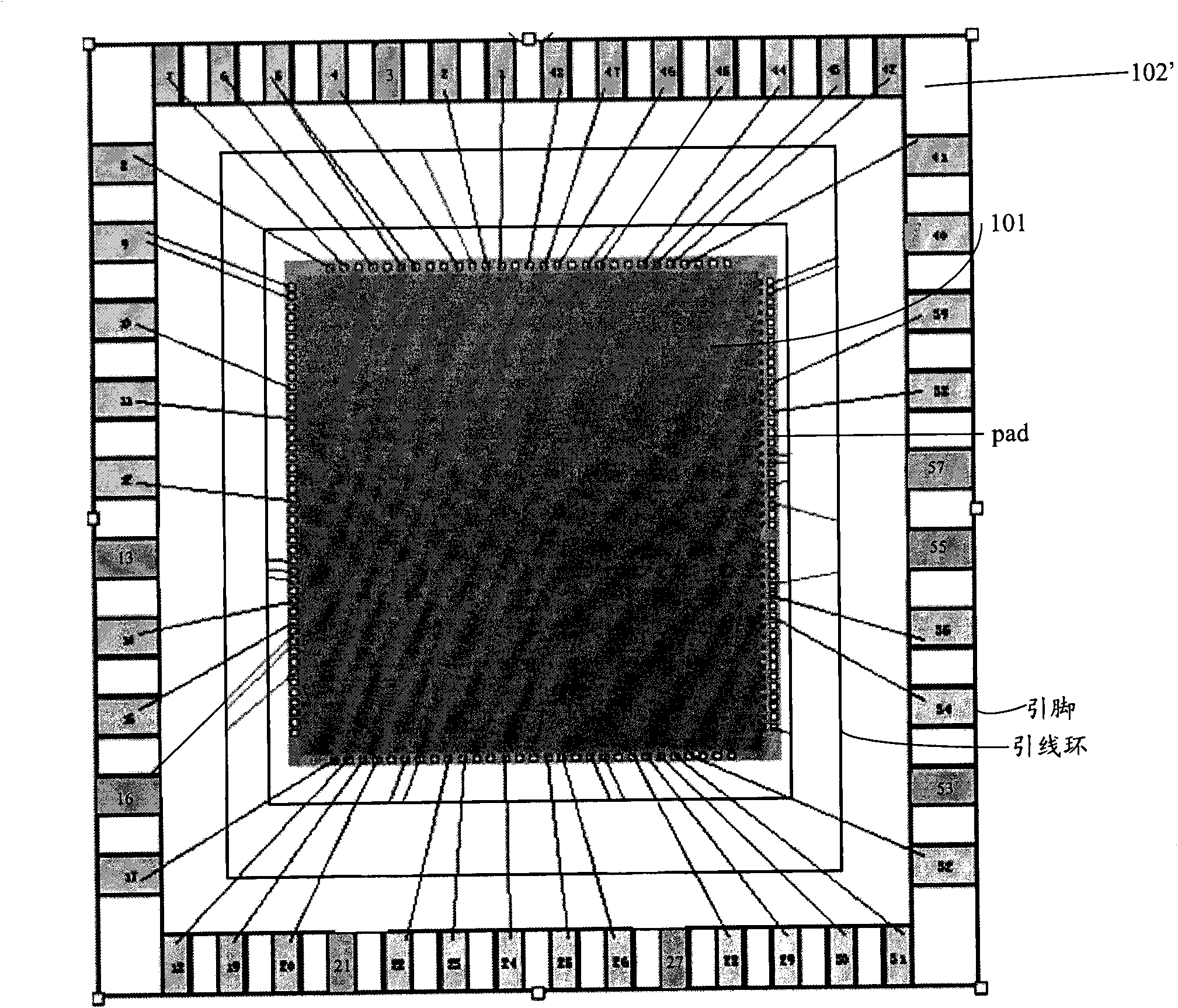

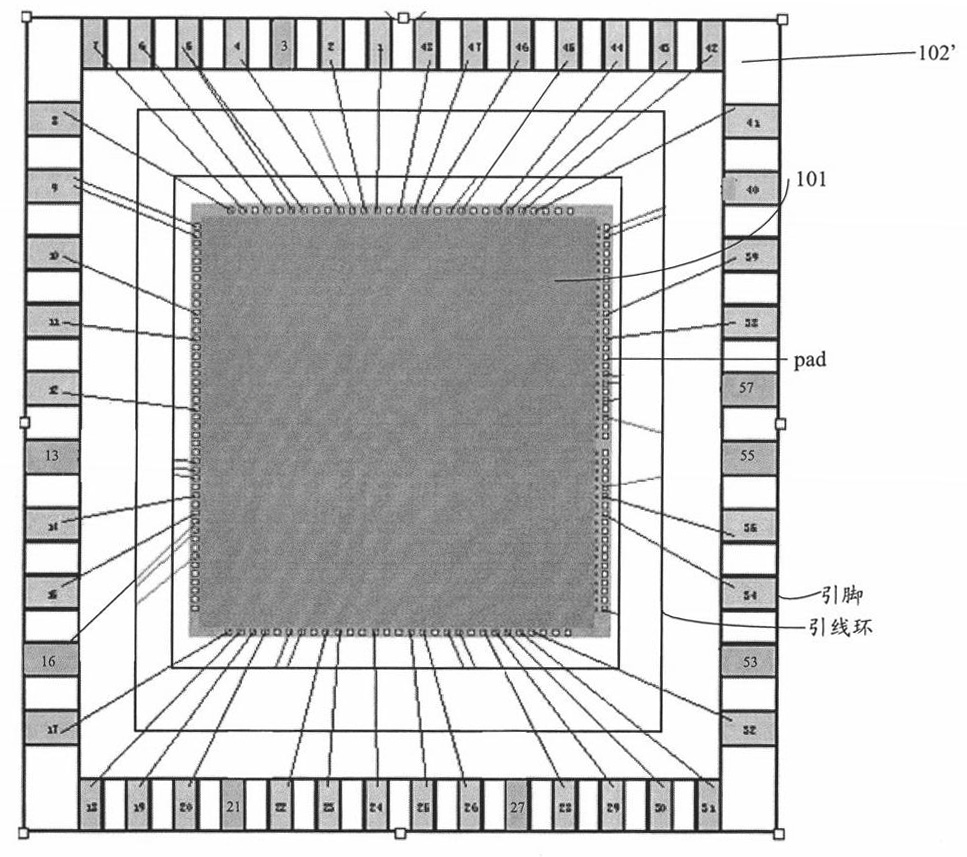

[0023] In order to solve the problem of insufficient pins on the lead frame 102 to wire all the contact pads on the chip, the present invention resets the lead frame. The lead frame includes a plurality of lead rings and a plurality of pins. The rings respectively surround the chip, and it is ensured that no electrical communication occurs between the multiple lead rings. When in use, when there are multiple pads with the same electrical characteristics on the chip, wire the pads with different electrical characteristics on the chip to different lead rings according to the different electrical characteristics of the pads, that is, there are multiple sets When connecting pads with different electrical characteristics, wire each group of pads with di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap