Flex-rigid wiring board and method of manufacturing the same

A rigid-flexible combination and manufacturing method technology, applied in printed circuit manufacturing, multilayer circuit manufacturing, printed circuit and other directions, can solve the problems of wiring short circuit or open circuit, affecting the insulation of the flexible part A, and reducing the quality, so as to protect the flexible part Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

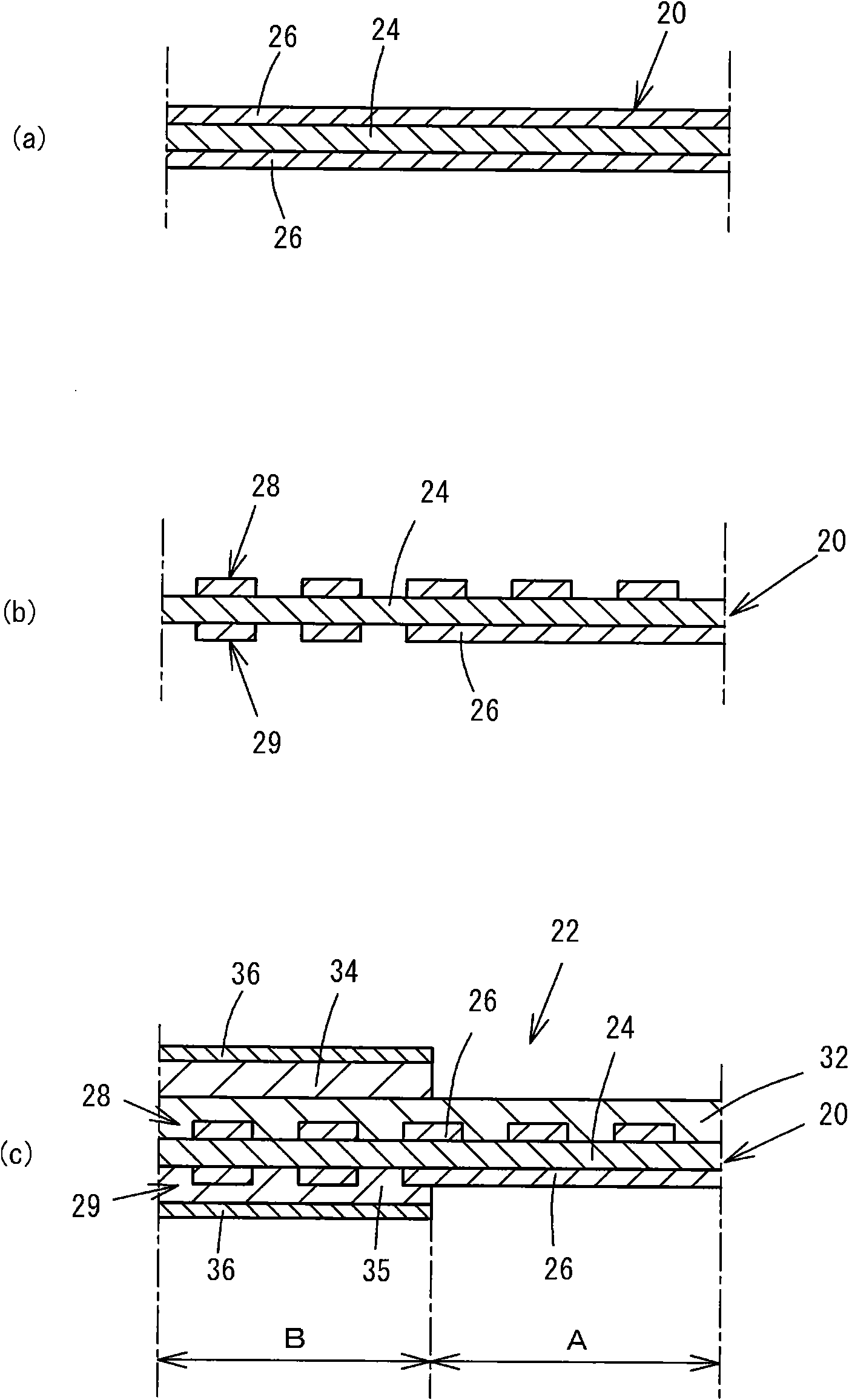

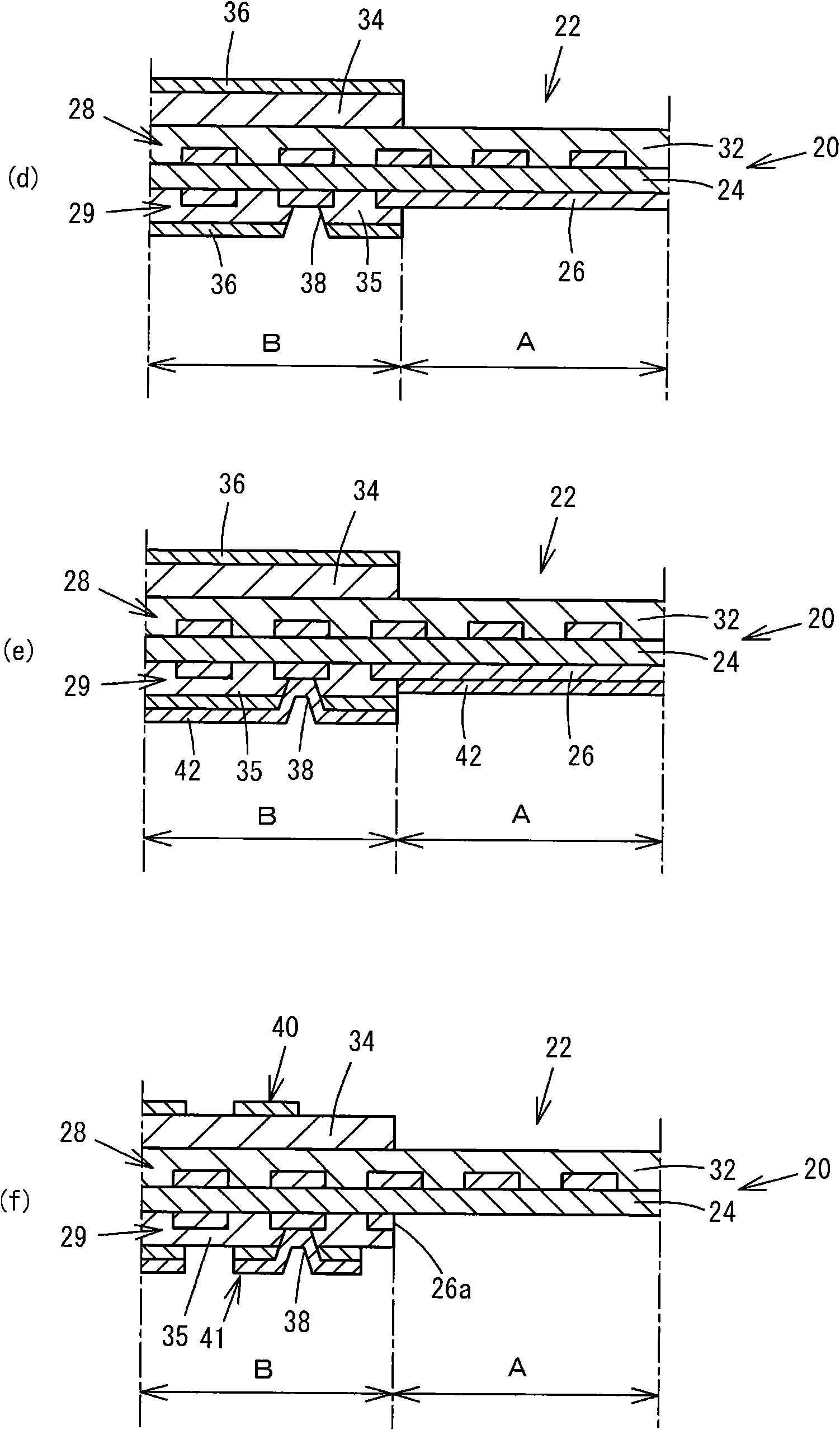

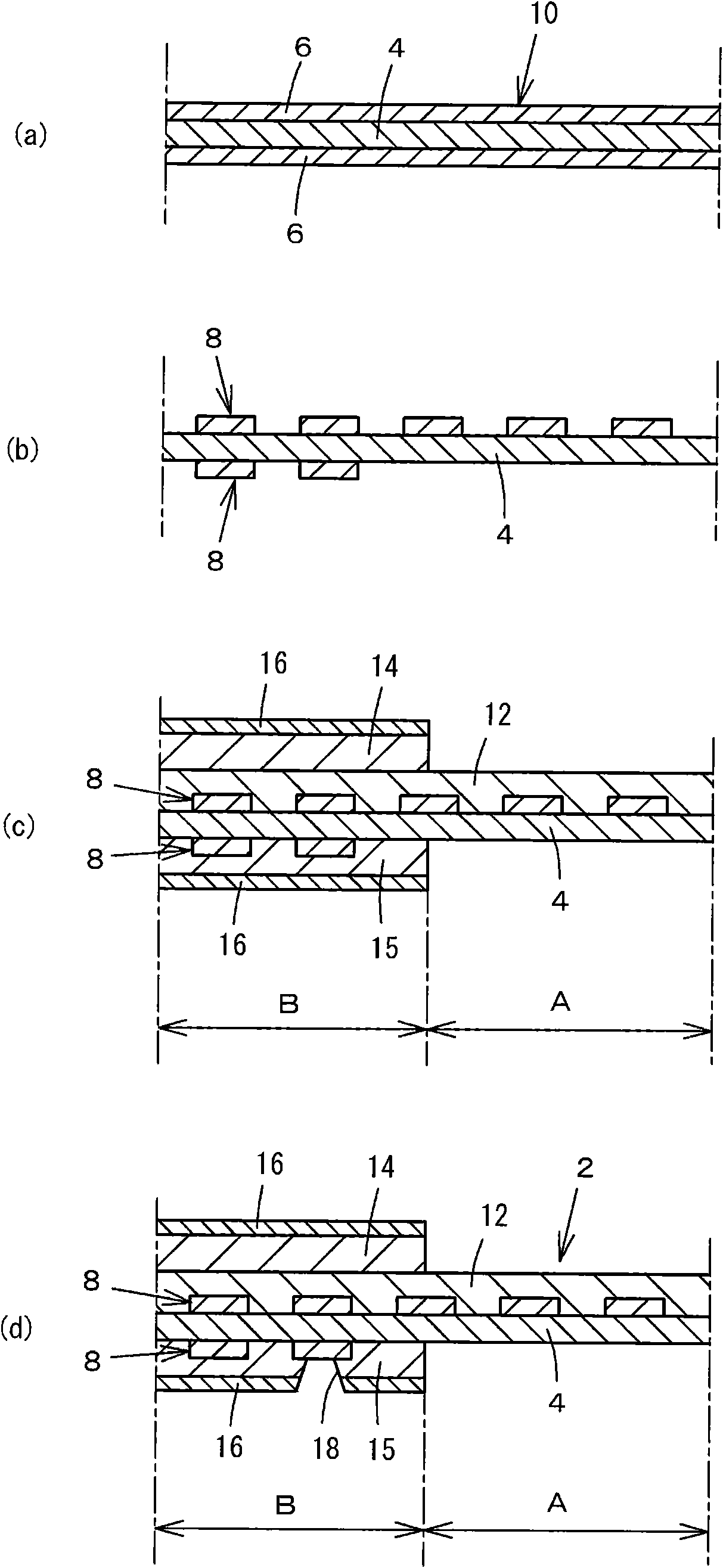

[0034] Below, according to figure 1 , figure 2 An embodiment of the rigid-flex circuit board of the present invention will be described. The structure of the rigid-flex circuit board 22 of this embodiment is integrally formed continuously: a soft flexible part A, and a rigid part B on which electronic parts are mounted and has rigidity. In the central portion of the rigid-flex circuit board 22, a base film 24 such as polyimide with a thickness of, for example, an insulating layer of about 10 to 50 μm is provided as a core base material, and a few μm to several tens of μm are attached to both sides thereof. The copper foil 26 of the conductor layer, thereby forming the copper clad laminate 20.

[0035] A predetermined circuit pattern 28 is formed on one surface of the copper-clad laminate 20, and a wiring layer is formed using copper foil, and a cover film 32 of an insulating layer is further laminated. The cover film 32 is formed of, for example, polyimide, is about ten t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com