High-pressure hydrolysis self-circulating device for oil

A self-circulating, high-pressure technology, applied in the field of self-circulating devices for high-pressure hydrolysis of grease, can solve the problems of low safety factor, time-consuming and electricity-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

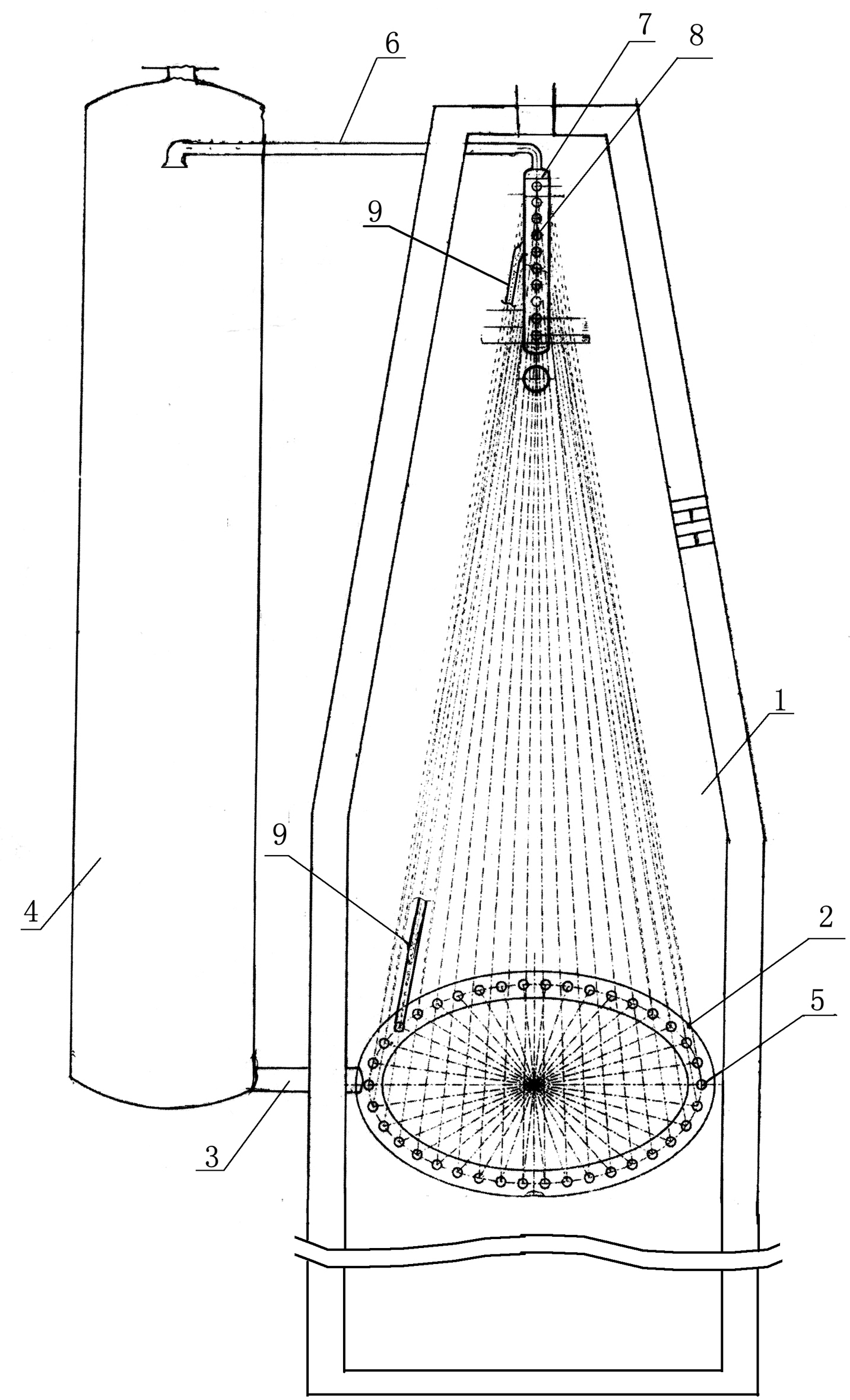

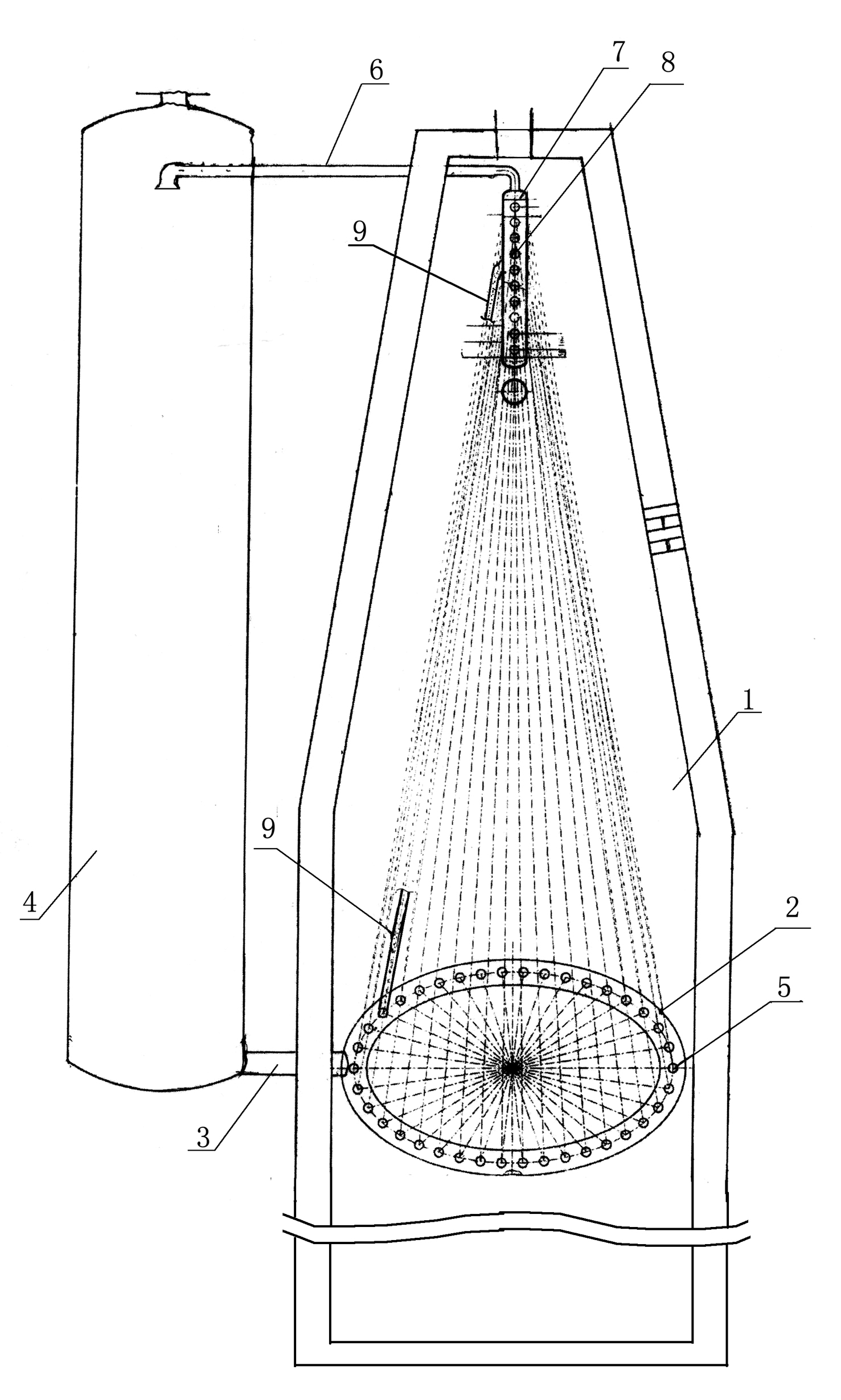

[0011] As shown in the drawings, the present invention includes a heating furnace body 1, a chassis tube 2 arranged in the heating furnace body 1 through a feed pipe 3 and a lower end of the hydrolysis tower 4, and more than 10 evenly arranged on the chassis tube 2 discharge hole 5, the vertical pipe 7 that is arranged on the upper end of the heating furnace body 1 through the discharge pipe 6 and the upper end of the hydrolysis tower 4, and more than 10 feed holes 8 that are evenly arranged on the vertical pipe 7. More than 10 vertical tubes 9 are uniformly distributed and connected to the feed holes 8 on the vertical tubes 7 and the discharge holes 5 of the chassis tubes 2 . Through the feed pipe 3, the medium mixed with oil and water in a weight ratio of 1:1 is sent into the heating chassis pipe 2, the vertical pipe 9 and the vertical pipe 7, and then heated through the vertical pipe 9 and the discharge pipe 6 Entering the hydrolysis tower 4, the main principle of the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com