Feed water degasifier for olar thermal power station

A solar thermal and degasser technology, applied in solar thermal power generation, liquid degassing, feed water heaters, etc., can solve problems such as difficult adjustment and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

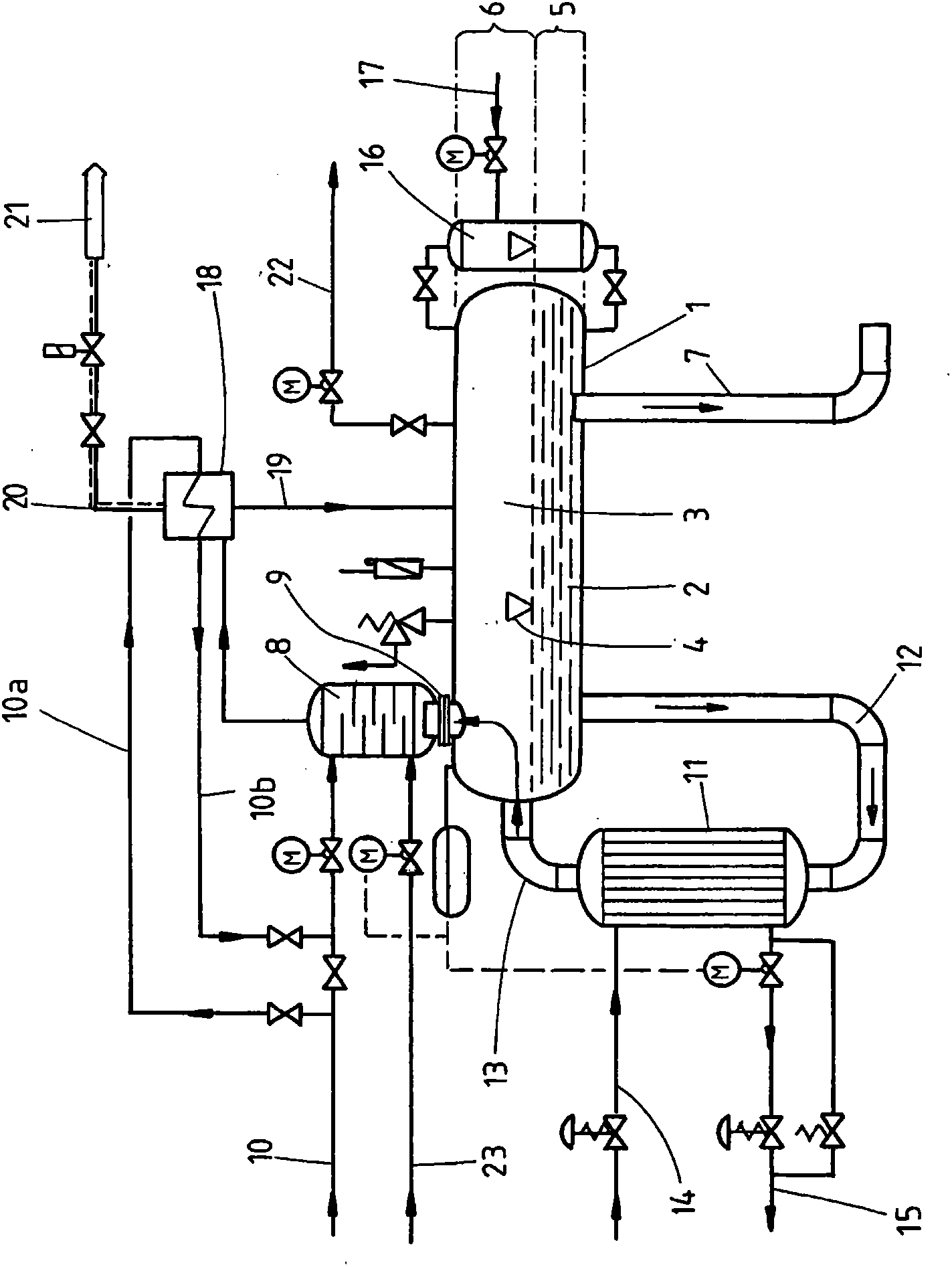

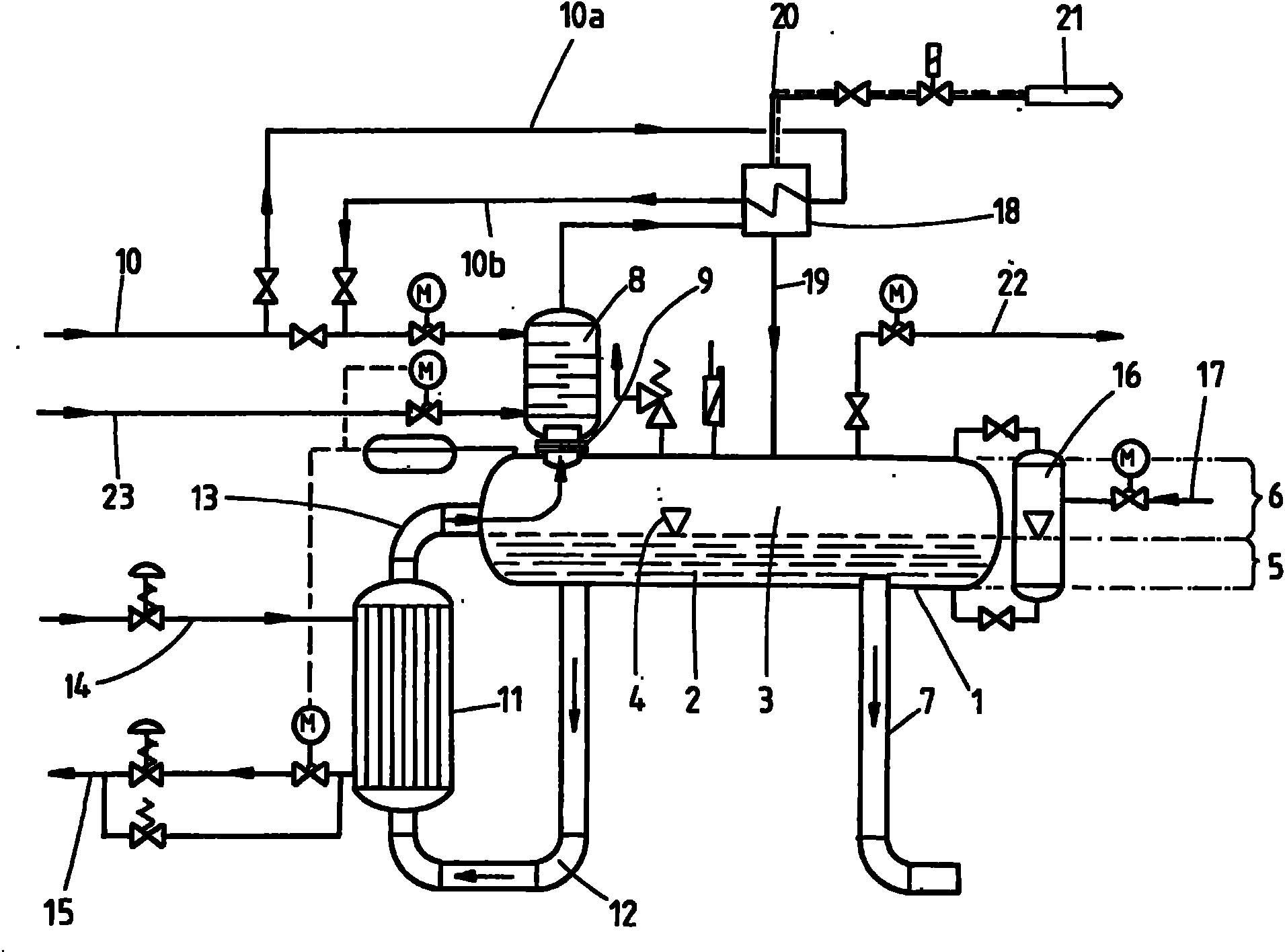

[0029] Said single figure shows a cylindrical water supply container or tank 1 lying horizontally and in which there is supply water 2 at the bottom and saturated steam 3 in the area formed above it. In the water supply tank 1 , the area filled with the supply water 2 reaching the liquid bath surface 4 is hereinafter referred to as the water supply area 5 , and the area formed above it is hereinafter referred to as the steam area 6 of the water supply tank 1 . In the water supply area 5, degassed water supply for the water / steam cycle of a connected solar thermal power plant (not shown) is supplied and prepared. The water supply tank 1 is connected to the water / steam circuit via a water supply line 7 whereby the water / steam circuit is supplied with degassed supply water 2 in the direction indicated by the arrow in the pipe 7 .

[0030] Arranged above the steam area 6 on the water supply tank 1 is a vertical cylindrical deaerator 8, which in the illustrated embodiment of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com