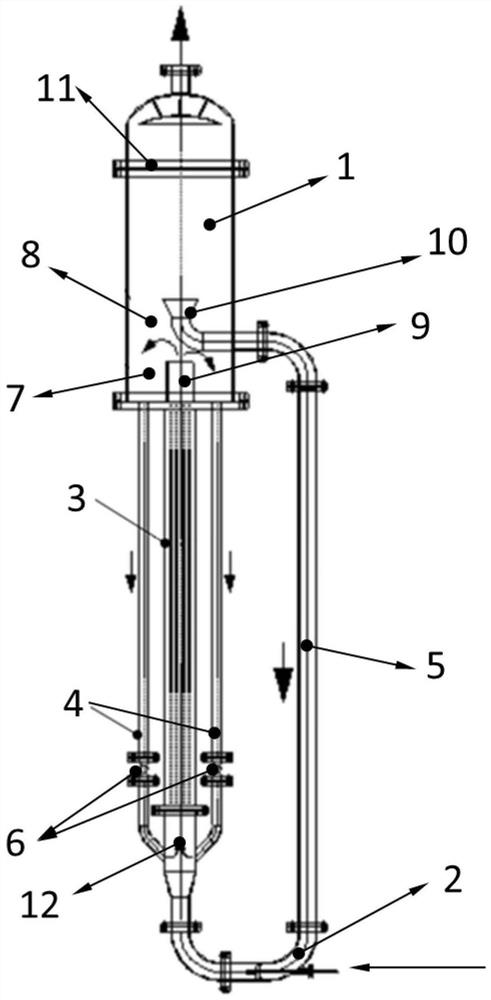

Mechanical auxiliary self-cleaning evaporation concentrator and evaporation concentration method

A mechanically assisted, self-cleaning technology, applied in vertical tube evaporators and other directions, can solve the problems of high price, increased industrial production and operation costs, environmental protection costs, large consumption, etc., to simplify the equipment structure and prevent scaling. The effect of adhesion and scaling prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0056] This technology was used in a mineral processing lye concentration recovery device, and the heat exchanger was opened before and after application to observe its fouling. Before adopting this technology, when the evaporative concentration device operated continuously for 40 days, the evaporation capacity decreased significantly, and the evaporative concentration could no longer operate normally, so it was necessary to stop the machine and open the heat exchanger for mechanical cleaning. Open the heat exchanger and observe. It can be seen that the wall surface of the heating tube of the heat exchanger is seriously scaled. The thickness of the scale layer is 3-5mm, and some tubes are blocked. Obviously, the decrease in evaporation is caused by the formation of scale. The result is a significant reduction in heat transfer efficiency. Using a new type of evaporative concentrator, when the device runs continuously for 120 days, the evaporation capacity does not decrease sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com