Steam generating device for high-power solar-thermal power station

A steam generating device and technology of photothermal power plants, applied in steam generation, steam generation methods, steam generation methods using solar energy, etc., can solve the problems of low steam quality, difficult manufacturing, high cost, etc., to improve reliability and cost Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

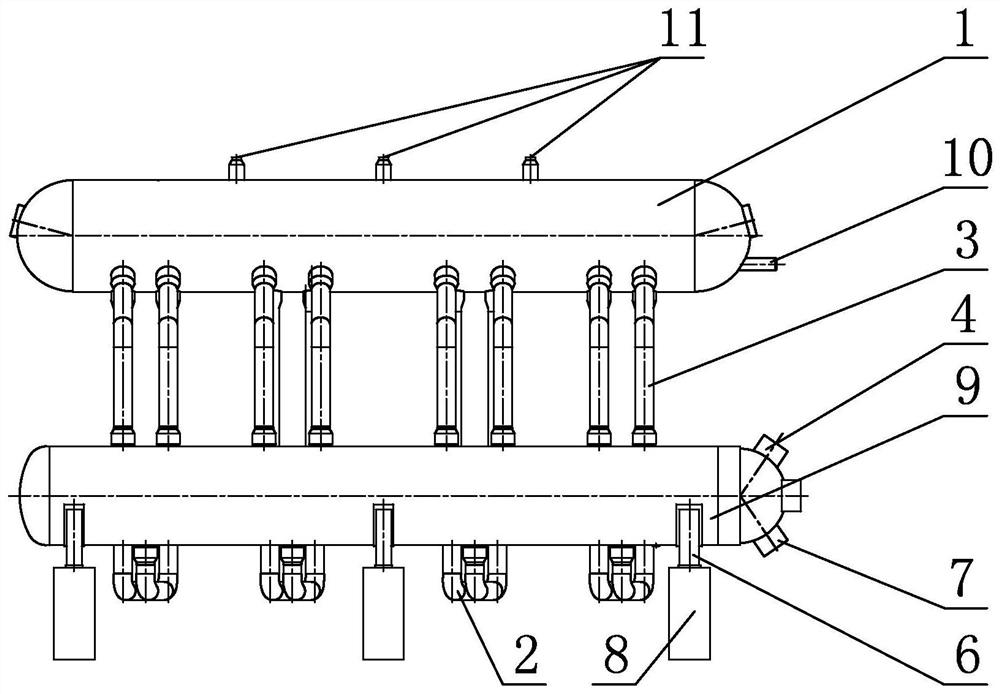

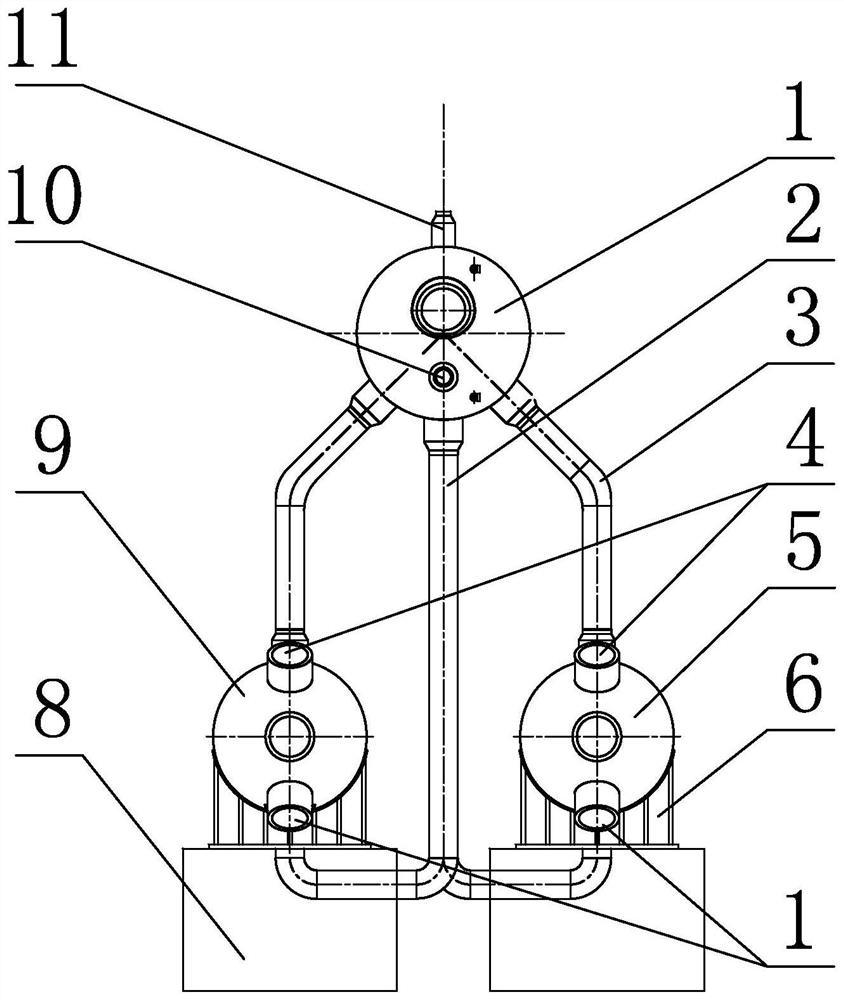

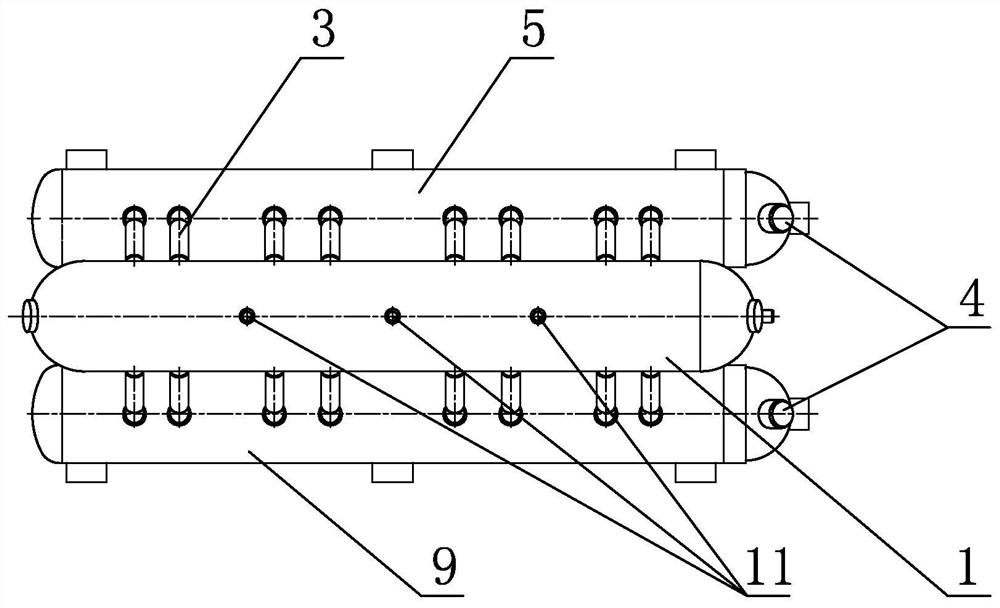

[0020] Specific implementation mode one: combine figure 1 Describe this embodiment mode, a kind of steam generation device for high-power photothermal power station of this embodiment mode, it comprises steam drum 1, evaporator A5, evaporator B9, several descending pipes 2 and several ascending pipes 3, evaporator A5 and The evaporator B9 is arranged in parallel in the horizontal direction, and the steam drum 1 is arranged in parallel above the evaporator A5 and the evaporator B9 in the horizontal direction, and the upper part of one end of the evaporator A5 and the evaporator B9 is respectively provided with a tube-side inlet 4, and the evaporator A5 and the evaporator The lower part of one end of the device B9 is respectively provided with a tube-side outlet 7, and one end of the steam drum 1 is provided with a water supply inlet 10, and the water supply inlet 10 communicates with the water storage area of the steam drum 1, and the upper part of the steam drum 1 is along th...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 Describe this embodiment, the evaporator A5 of this embodiment communicates with the water storage area inside the steam drum 1 through four downcomers 2, and the evaporator B9 communicates with the water storage area inside the steam drum 1 through four downcomers 2. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the bottom of the evaporator A5 of this embodiment communicates with the steam-water separation area inside the steam drum 1 through four rising pipes 3, and the bottom of the evaporator B9 communicates with the steam-water separation area inside the steam drum 1 through four rising pipes 3 . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com