Fractal design method for roller bit gear teeth structure

A roller cone bit and design method technology, applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of obvious isotropy and single type of tooth structure design of the roller cone bit, so as to improve the rock breaking efficiency and operation The effect of convenience, great implementation value and social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

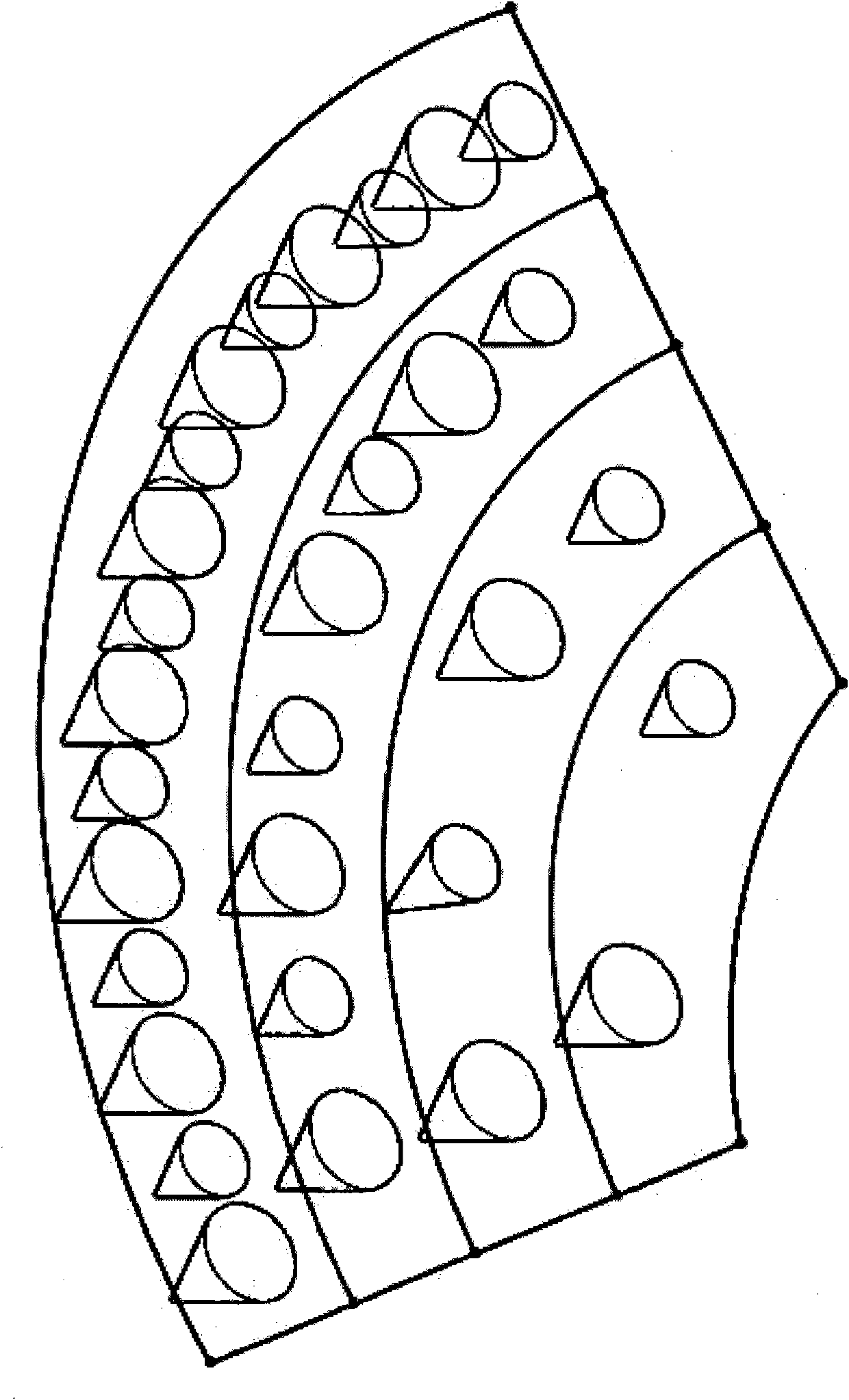

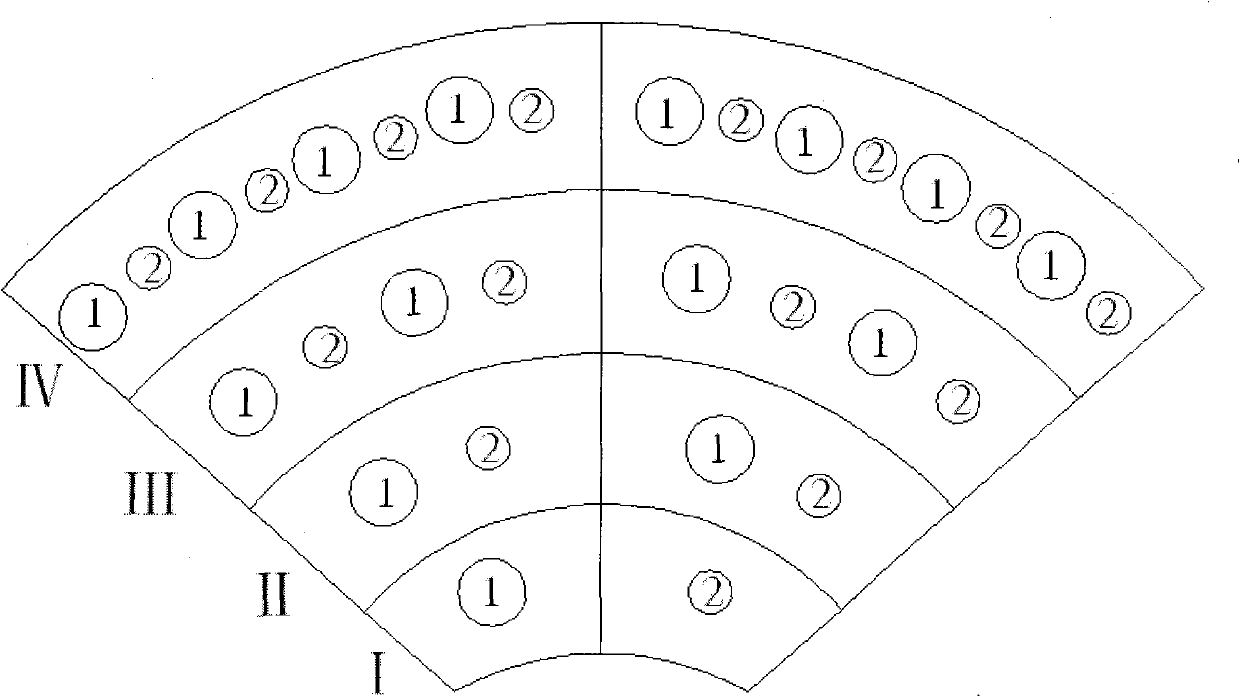

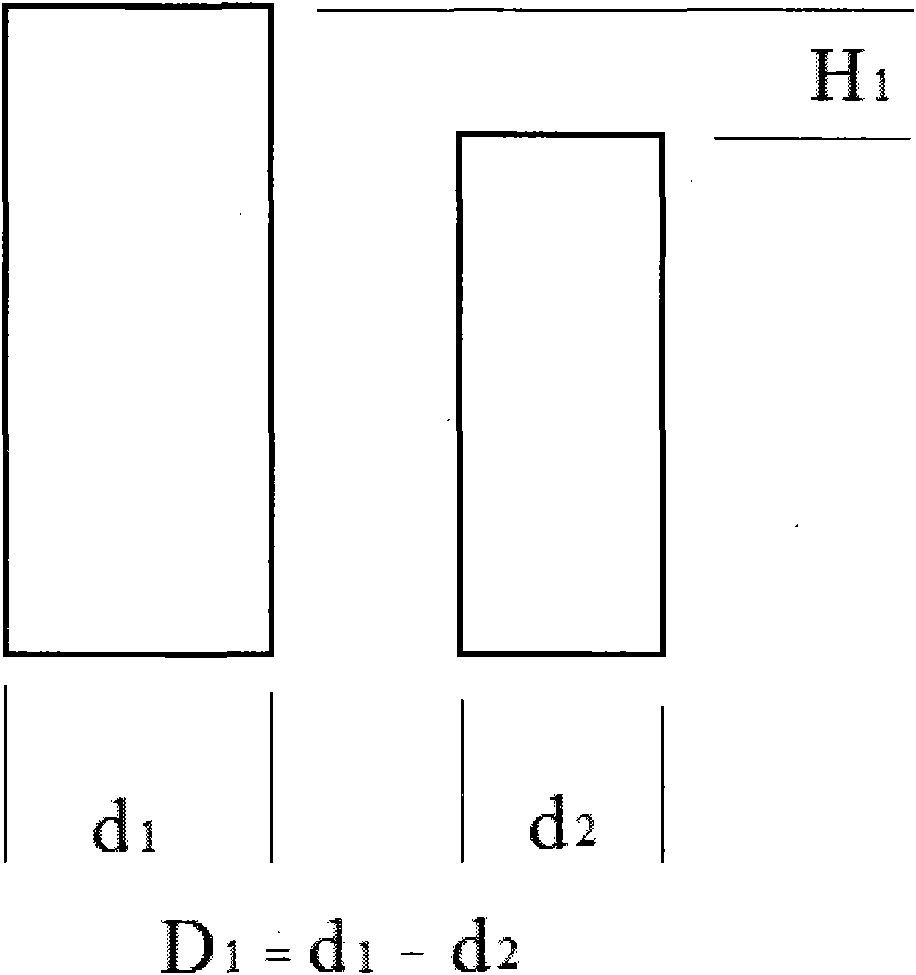

[0023] combine figure 1 , figure 2 As shown, the fractal design method of the gear tooth structure of this roller cone bit is composed of two consecutively arranged teeth of different heights with the initial value of the fourth order, and the adjacent teeth in the same order are offset from each other, and the law is The 1st order fractal tooth distribution of the 4th order fractal tooth distribution consists of 2 teeth, see image 3 As shown, there is a deviation H between the tooth height and tooth diameter of the first stage two teeth 1 、D 1 ; The second-order fractal tooth distribution is composed of 2 2 Composed of two gear teeth, the 2 2 A gear tooth consists of 2 groups of first-order gear teeth, that is, the 2 2 Each gear tooth is divided into 2 groups, each group has 2 gear teeth, and there is a deviation H between the tooth height and tooth diameter of the 2-group shaped gear teeth in the second stage 2 、D 2 ; The third-order fractal gear tooth distribution ...

Embodiment 2

[0025] combine Figure 4 , Figure 5 As shown, the tooth distribution of the roller cone bit with the initial value of 3 in the third order is composed of teeth of different heights arranged continuously in each order, and there is mutual offset between adjacent teeth in the same level, and its The rule is that the first-order fractal tooth distribution of the third-order fractal tooth distribution consists of three teeth, see Figure 6 As shown, there is a deviation H between the tooth height and tooth diameter of the first three teeth 1 、D 1 ; The second-order fractal tooth distribution is composed of 3 2 Composed of 3 gear teeth, these 3 2 A gear tooth consists of 3 sets of first-order gear teeth, that is, the 3 2 Each gear tooth is divided into 2 groups, each group has 3 gear teeth, and there is a deviation H between the tooth height and tooth diameter of the 3-group shaped gear teeth in the second stage 2 、D 2 ; With the increase of order, the number of gear teeth ...

Embodiment 3

[0027] combine Figure 7 , Figure 8 As shown, the tooth distribution of the roller cone bit with the initial value of 3 in the third order is composed of teeth of different heights arranged continuously in each order, and there is mutual offset between adjacent teeth in the same level, and its The rule is that the first-order fractal tooth distribution of the third-order fractal tooth distribution consists of three teeth, see Figure 9 As shown, there is a deviation H between the tooth height and tooth diameter of the first three teeth 1 、D 1 , the characteristic of the deviation is that there is a deviation H between the tooth height and tooth diameter of the first tooth and the third tooth among the three teeth 1 、D 1 , there is a deviation H between the tooth height and tooth diameter of the third tooth and the second tooth 1 、D 1 , the tooth height of the internal gear teeth of this stage is high and low, and the tooth diameter is large and small; the number of teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com