Mechanism for realizing adjustable equipment rotating angle

A technology of rotation angle and equipment, which is applied in the direction of mechanical equipment, belts/chains/gears, transmission devices, etc., can solve the problems of complex use and adjustment, damage, limited angle of rotation and swing head, etc., and achieve a wide range of adjustable angles and good use effect, the effect of smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

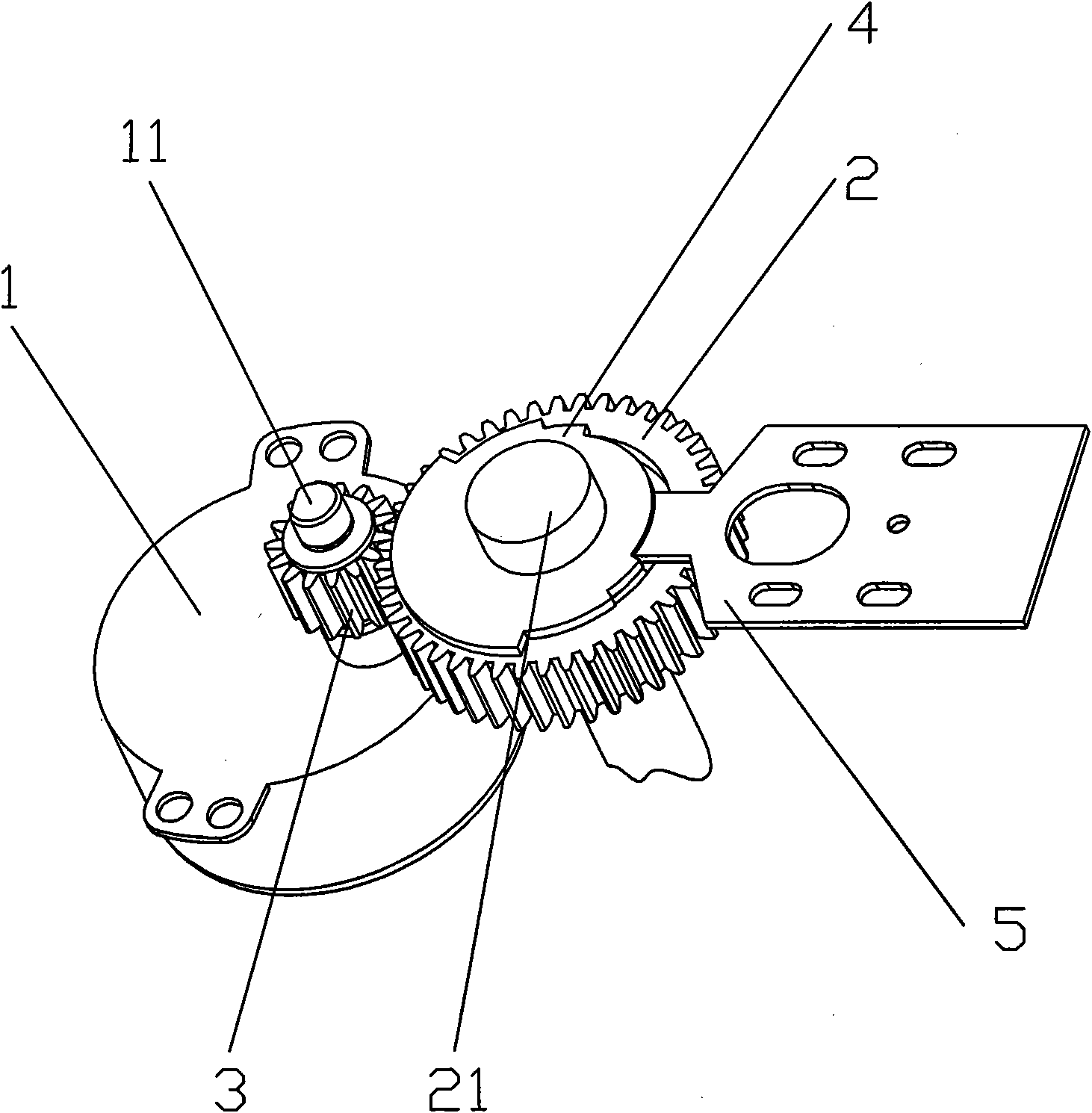

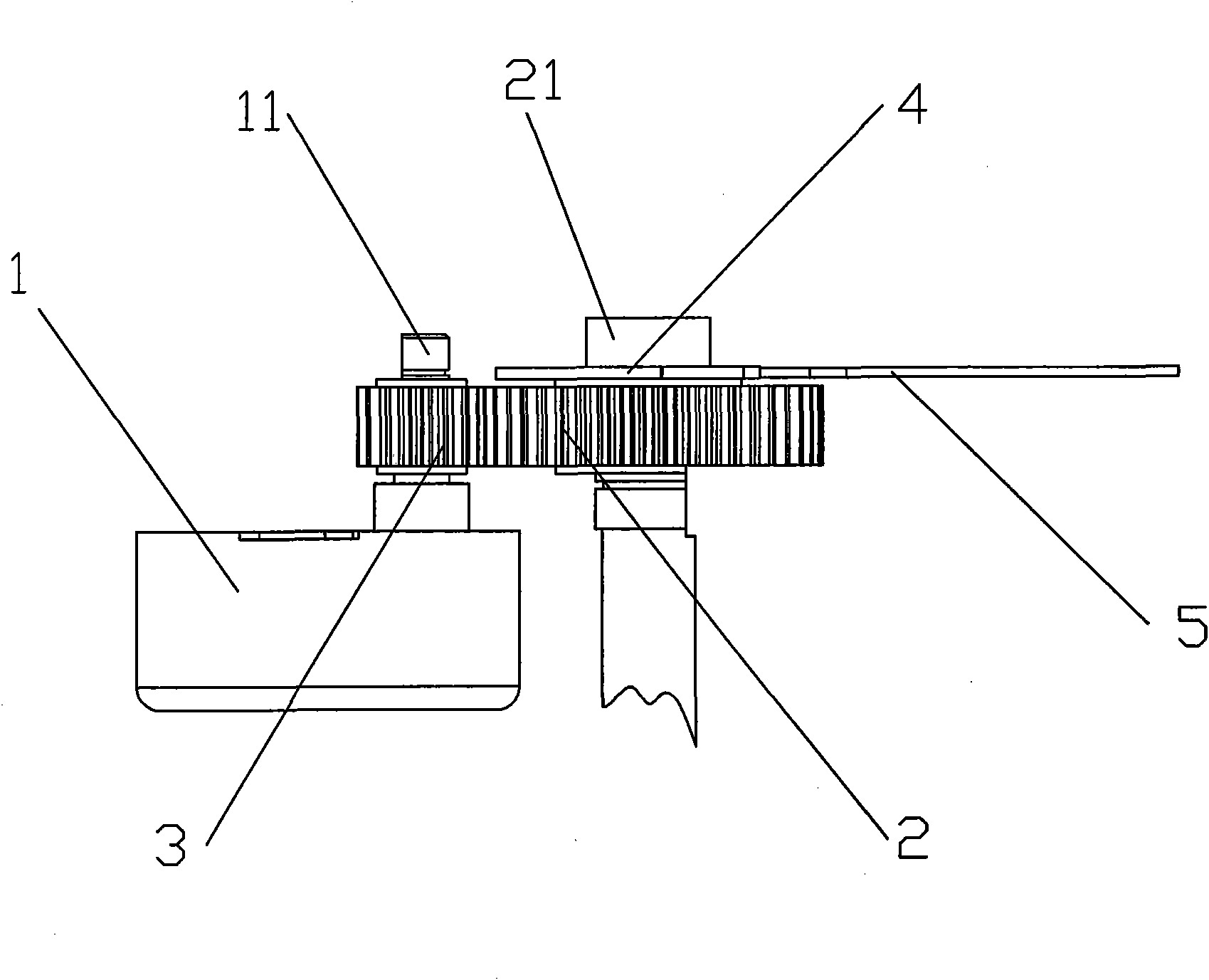

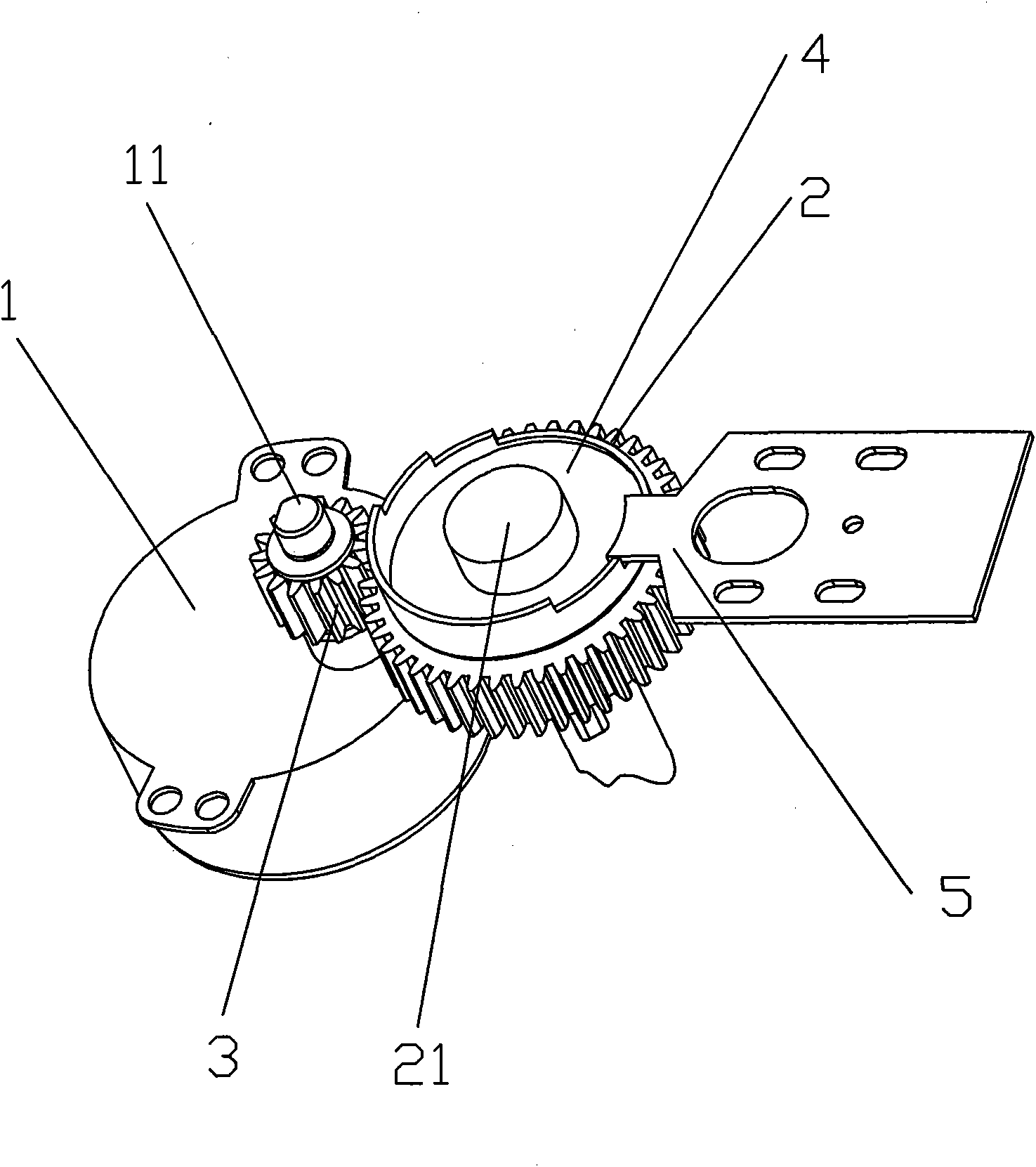

[0017] refer to figure 1 and figure 2 , a mechanism for realizing the adjustable rotation angle of the equipment in the present invention includes a synchronous motor 1, a driving gear 3 is set on the motor shaft 11 of the synchronous motor 1, and a driven gear 2 meshes with the driving gear 3, wherein the reversible synchronous The motor 1 drives the driven gear 2 to rotate through the driving gear 3 . The driven gear 2 is sleeved on the driven shaft 21, and an angle adjustment piece 4 is also sleeved on the driven shaft 21, and the outer edge of the angle adjustment piece 4 is arc-shaped. There are at least two steps of step-shaped limiting grooves on the outer edge of the angle-adjusting piece 4, and a movable baffle plate 5 is driven by a driver to extend into different limiting grooves to control the driven shaft 21 to achieve different angles of rotation and movement. The baffle 5 can be optionally installed on the shell or bracket of the fixed synchronous motor and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com