Liquid crystal display and substrate

A liquid crystal display and substrate technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of increasing the production time of the process, and achieve the effect of reducing the alignment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The liquid crystal display in this embodiment includes an array substrate and a color filter substrate, and combined alignment marks are provided on the array substrate and the color filter substrate, and the combined alignment marks include coarse alignment marks and fine alignment marks, The fine alignment mark is located in the peripheral surrounding area of the coarse alignment mark;

[0067] The coarse alignment marks on the array substrate correspond to the coarse alignment marks on the color filter substrate;

[0068] The fine alignment marks on the array substrate correspond to the fine alignment marks on the color filter substrate.

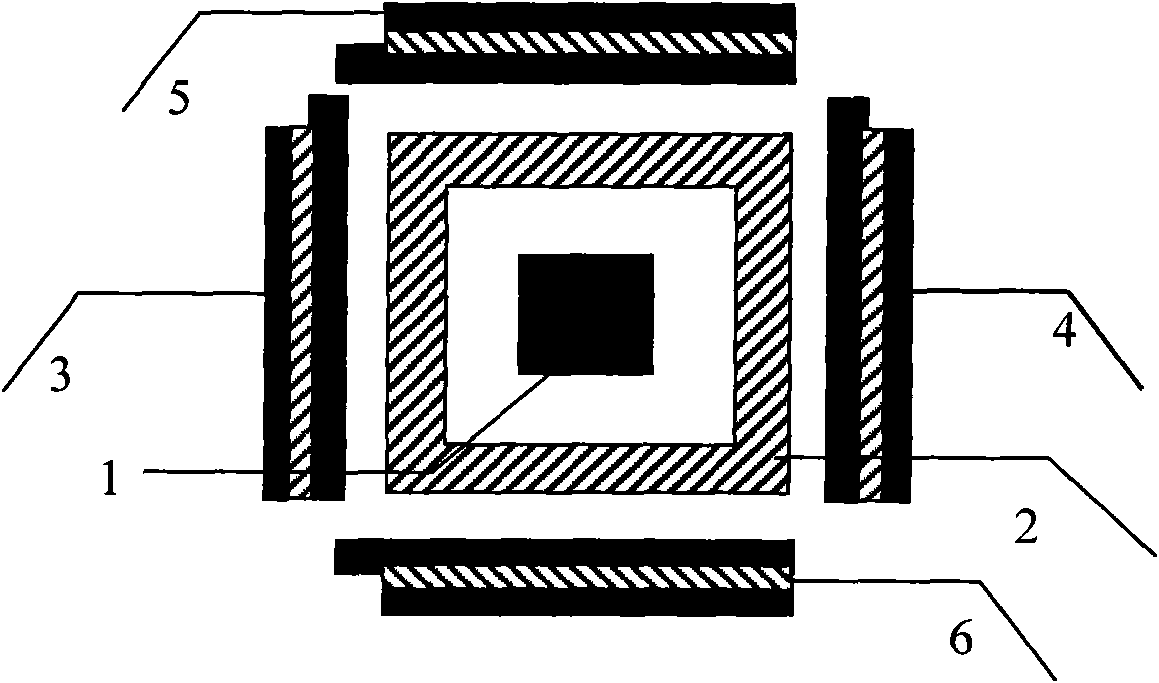

[0069] figure 1 It is a structural schematic diagram of the alignment mark provided in the liquid crystal display of the present invention.

[0070] These include:

[0071] Coarse alignment marks (1) on the array substrate;

[0072] Coarse alignment marks (2) on the color filter substrate;

[0073] A fine alignment mark (3) ...

Embodiment 2

[0100] In this embodiment, the structure of the liquid crystal display is basically the same as that of the liquid crystal display in Embodiment 1. The difference is the design of the fine registration marks.

[0101] In this embodiment, the design of the fine alignment mark is as follows:

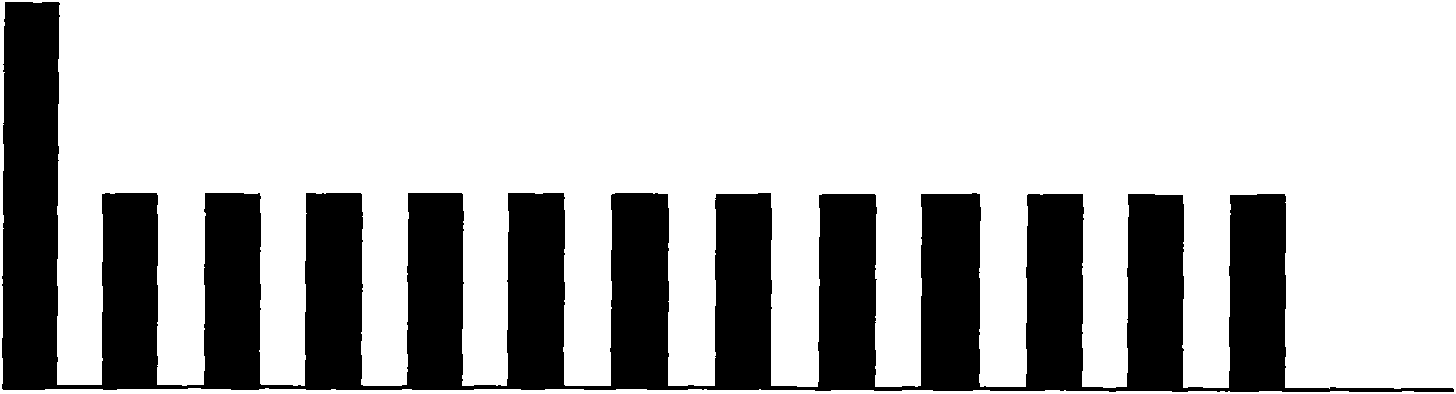

[0102] The fine alignment mark provided on the array substrate is composed of a rectangular initial alignment mark symbol and seven inverted L-shaped fine alignment mark symbols.

[0103] Wherein, the initial alignment mark symbol is positioned at the leftmost side of the fine alignment mark, and is longer than the rest of the alignment mark symbols, and the rest of the alignment mark symbols are equal in length (such as Figure 10 shown);

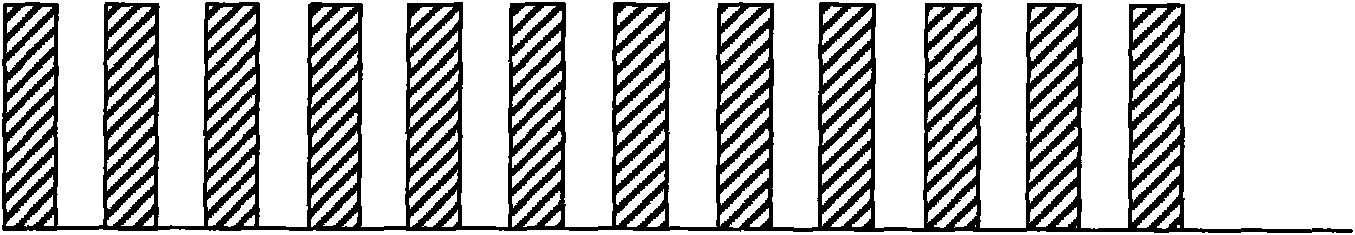

[0104] The fine alignment mark set on the color filter substrate consists of a rectangular initial alignment mark symbol and seven L-shaped fine alignment mark symbols.

[0105] Wherein, the initial alignment mark symbol is positioned at the far rig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com