Substrate transfer apparatus and substrate transfer method

A substrate conveying and substrate technology, which is applied to conveyor objects, transportation and packaging, and devices for coating liquids on surfaces, etc. The effect of printing marks and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

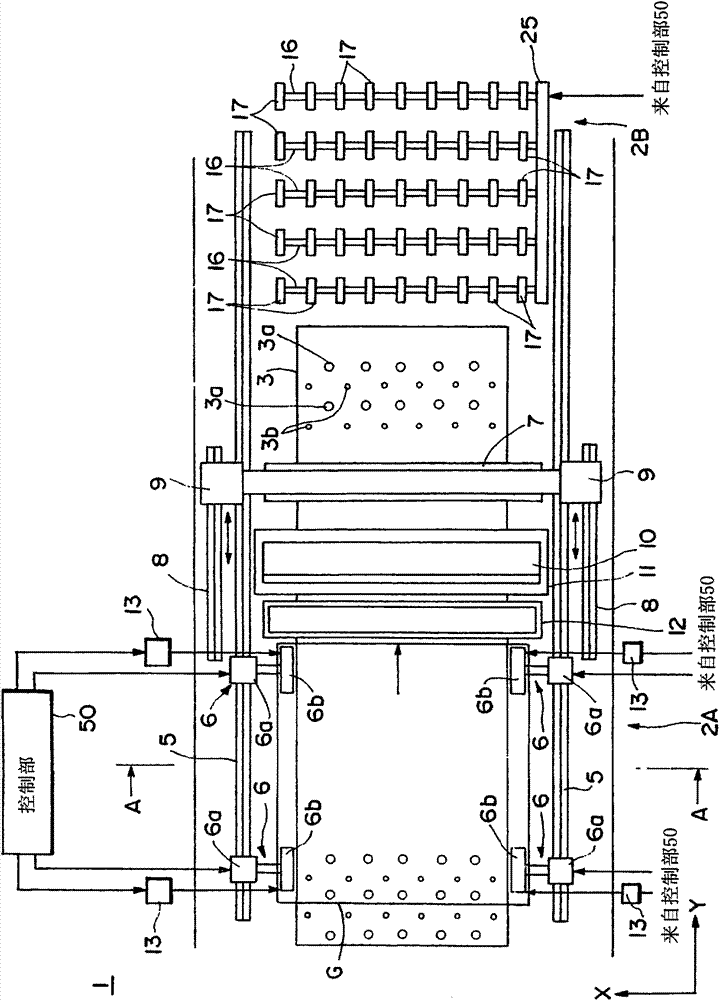

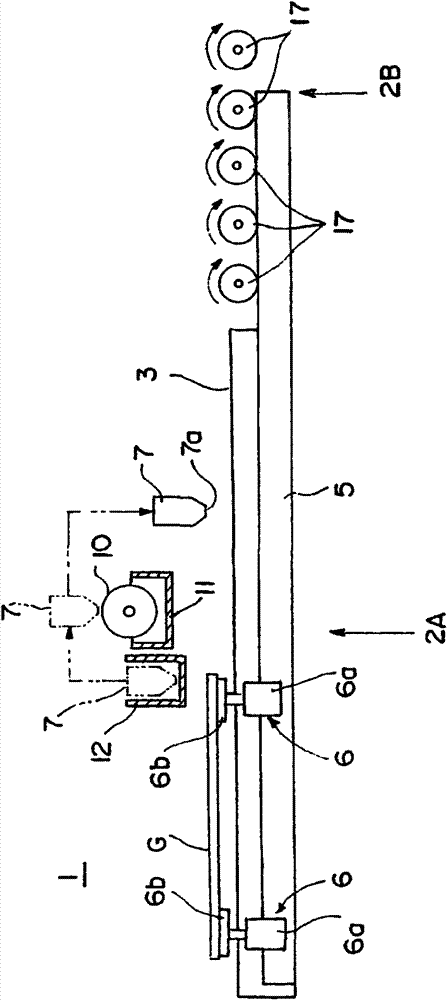

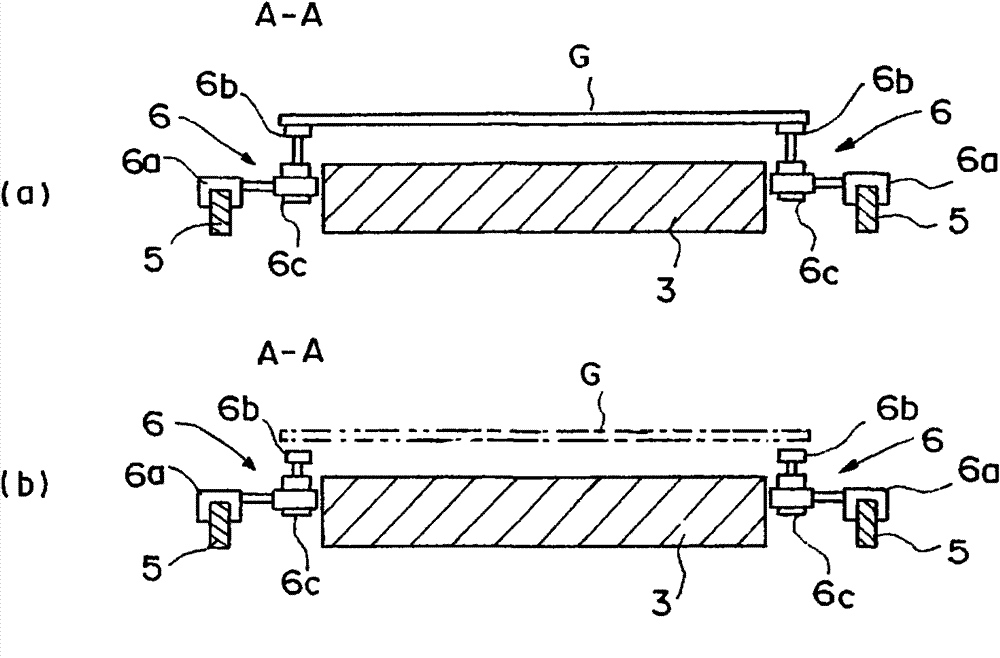

[0055] Hereinafter, embodiments of the substrate transfer device of the present invention will be described with reference to the drawings. First, according to Figure 1 to Figure 4 A first embodiment of the substrate transfer device will be described. In addition, in this embodiment, the case where a substrate conveyance apparatus is applied to the resist coating processing unit which applies resist coating to the glass substrate which is a substrate to be processed is demonstrated as an example.

[0056] This substrate conveyance apparatus 1 includes a floating conveyance unit 2A for floatingly conveying a glass substrate G and a rolling conveyance unit 2B for obtaining and rollingly conveying a substrate G from the floating conveyance unit 2A. The substrate G is so-called advective conveyance.

[0057] In the floating conveyance section 2A, a floating table 3 extending in the Y direction, which is the substrate conveying direction, is provided. On the upper surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com