Fabric draw-off device

A technology of fabrics and circular knitting machines, applied in the direction of knitting, weft knitting, textiles and papermaking, which can solve time-consuming and troublesome problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

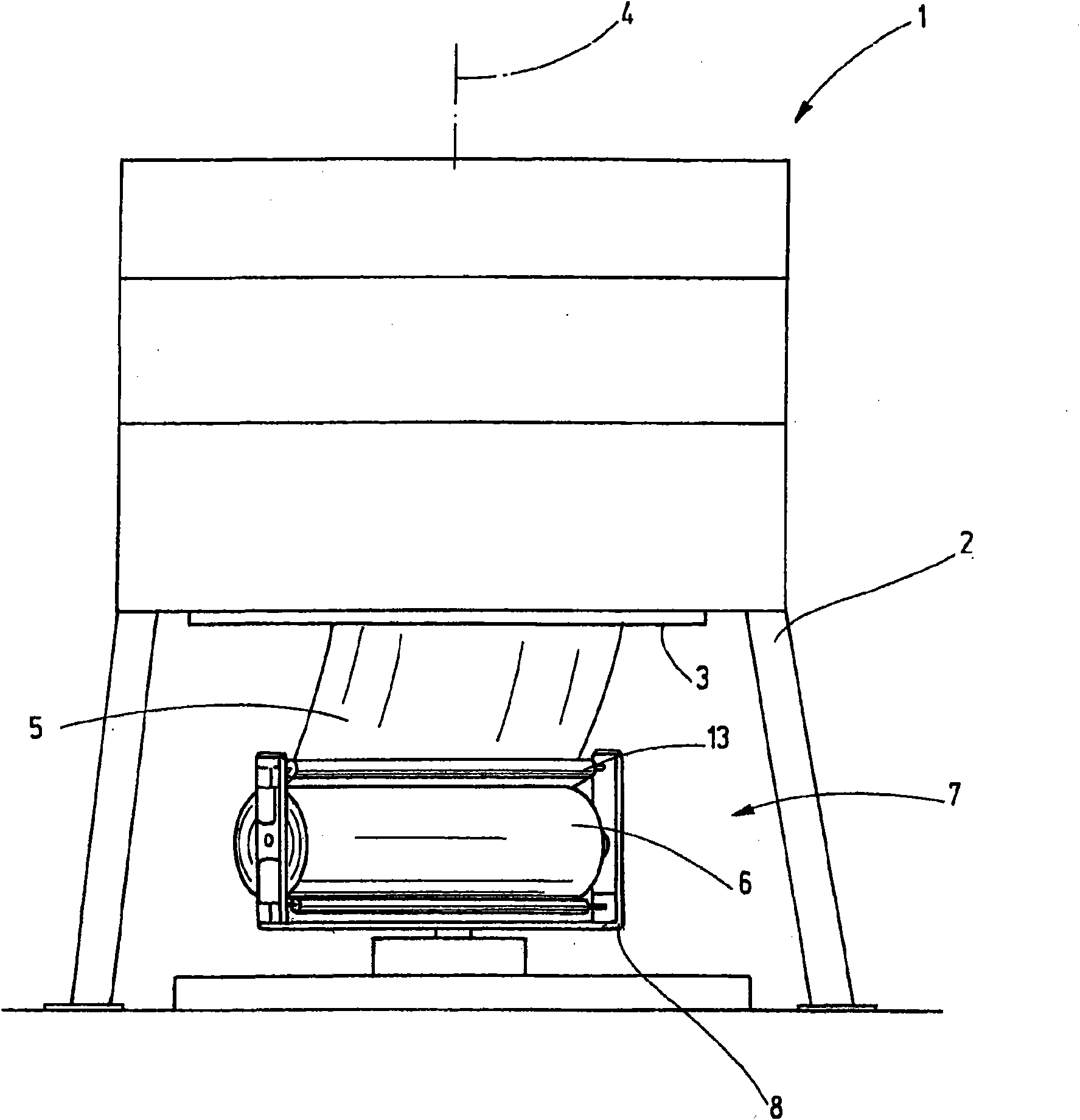

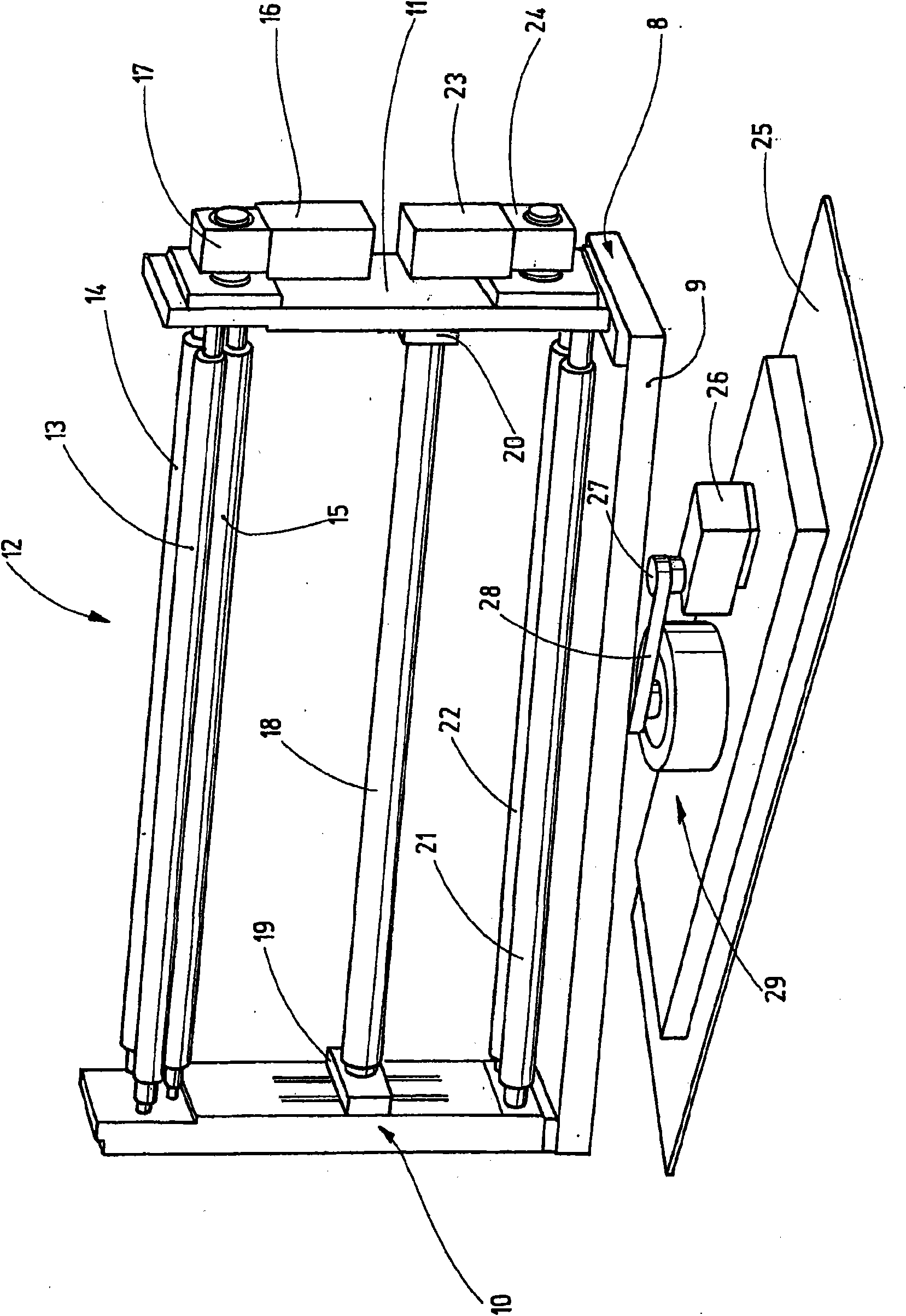

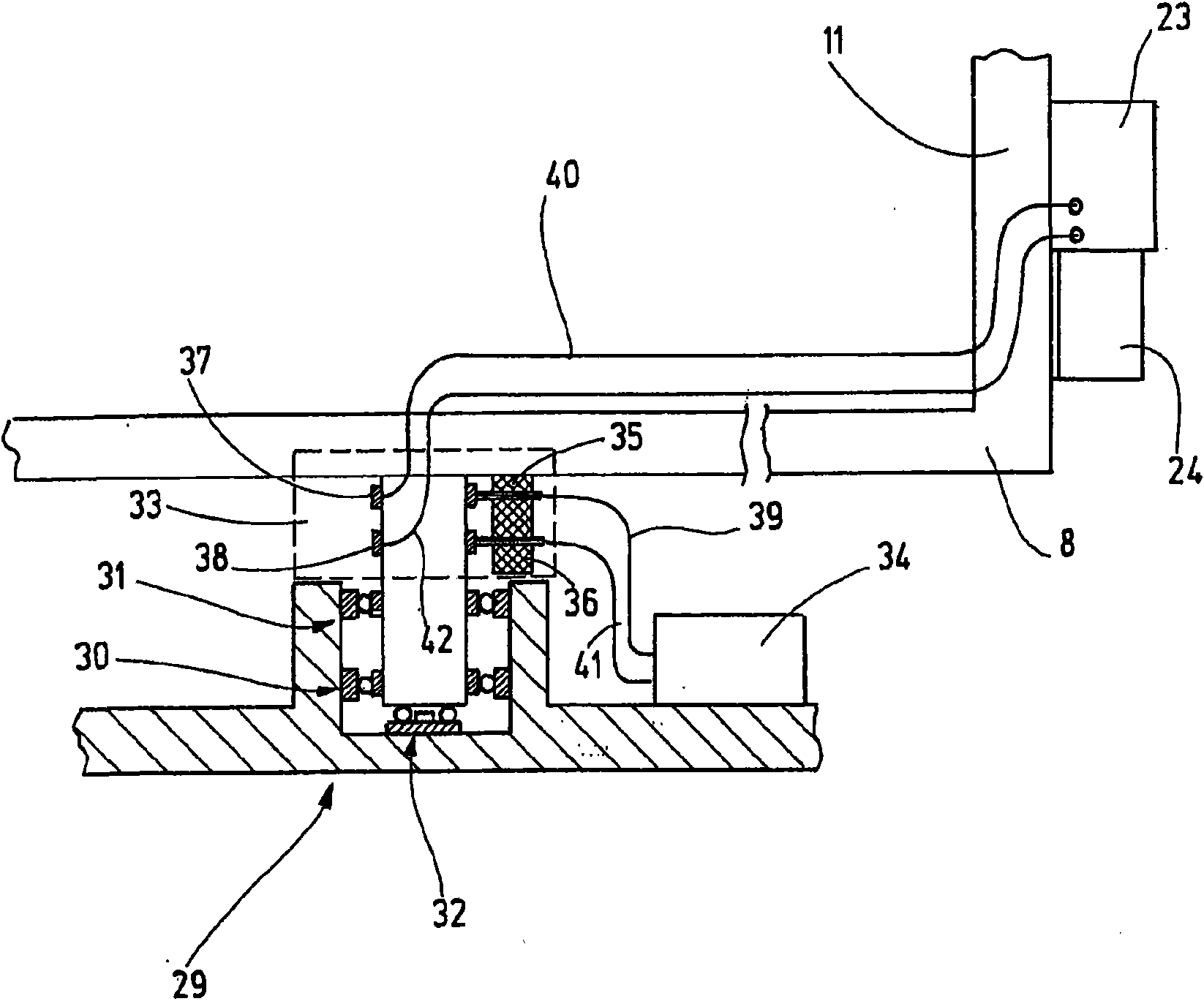

[0035] With reference to the accompanying drawings, especially figure 1 , where a circular knitting machine 1 is shown highly schematically. The rotary knitting machine 1 comprises a stationary frame 2 supporting a hollow knitting cylinder 3 about a vertical axis of rotation 4 . A main drive (not shown) is provided for rotating the knitting cylinder 3 in a defined direction.

[0036] In operation, the knitwear 5 leaves the cylinder 3 and travels downwards. The knitwear 5 is usually tubular. It has to be coiled to form bales 6 or rolls. The knitwear 5 can be slit longitudinally and spread out into individual pieces to be rolled up. Alternatively, the fabric tube may remain uncut. In the latter case, the knitwear forms a double layer in each winding of the bale 6 .

[0037] The extraction device 7 is located below the knitting cylinder 3 for extracting the knitwear 5 downwards and for winding the knitwear 5 . The extraction device 7 pulls down and holds the fabric 5, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com