Handle waterproof structure of electric tool

一种防水结构、电动工具的技术,应用在机动工具、制造工具、电路等方向,能够解决正反切换手柄防水结构没有考虑充分等问题,达到防水性能提高、提高防水性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

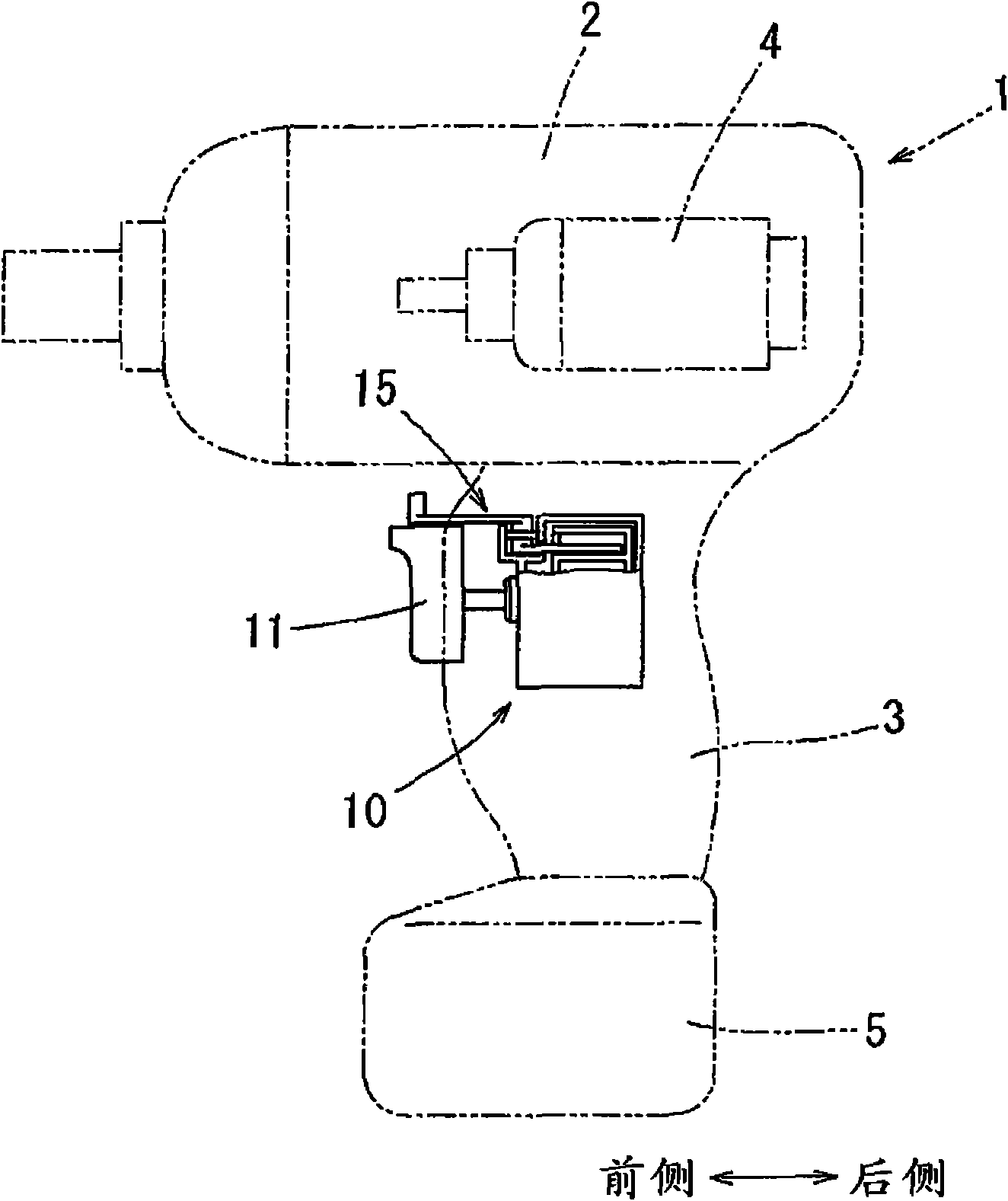

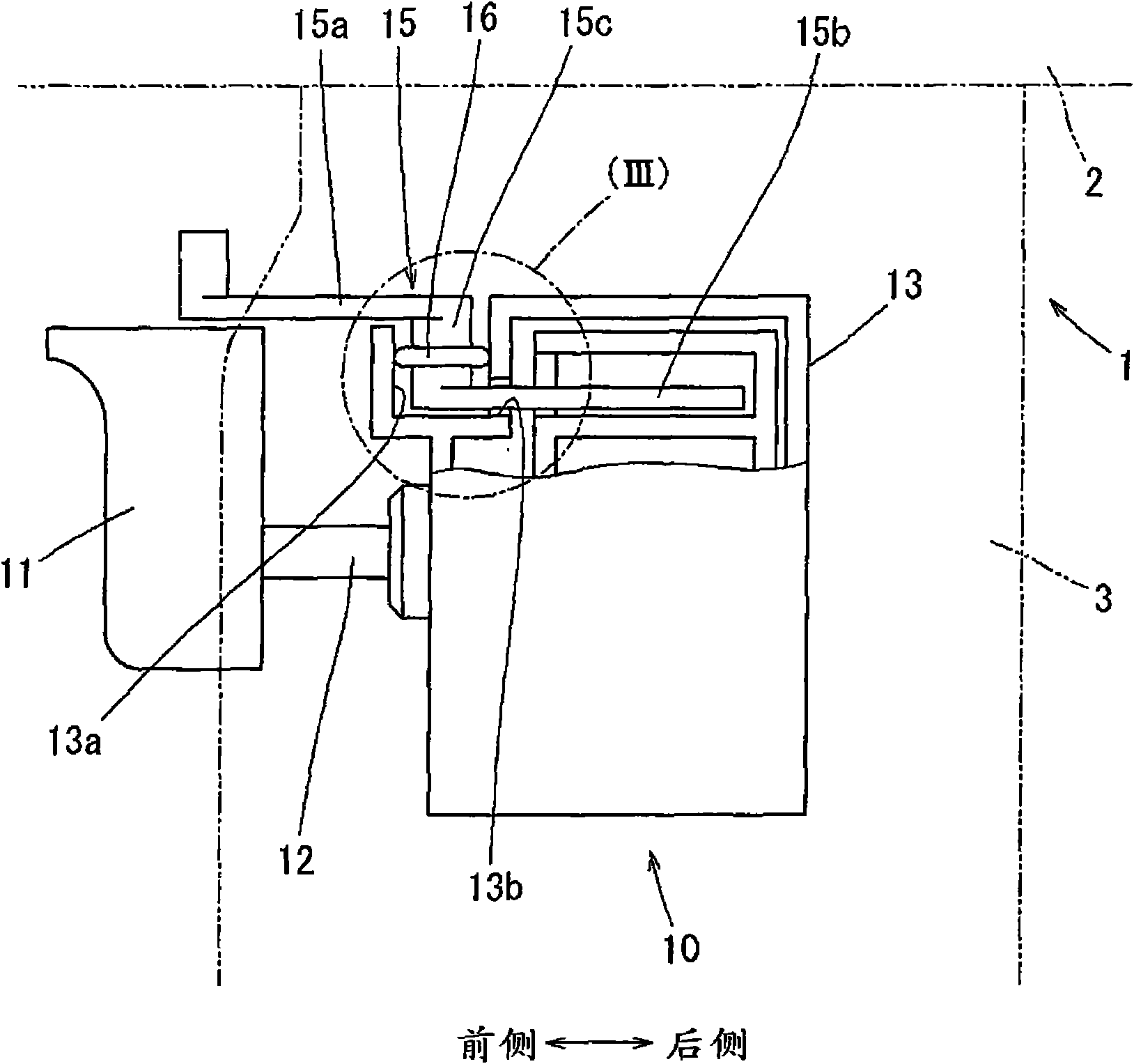

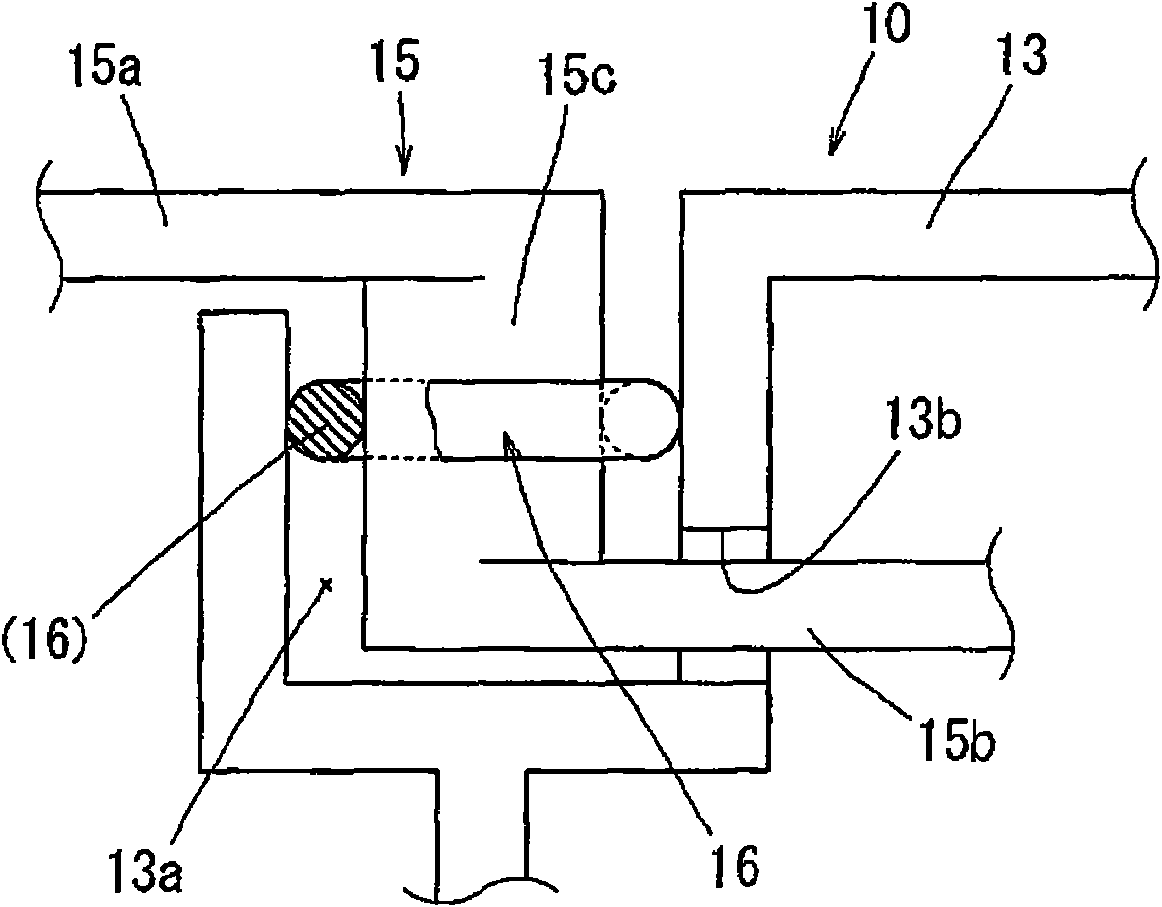

[0027] Below, according to Figure 1 to Figure 11 Embodiments of the present invention will be described. figure 1 The switch body 10 having the waterproof structure of the first embodiment and the electric screwdriver 1 having the switch body 10 are shown. The switch main body 10 is assembled in the handle part 3 of the electric screwdriver 1 . The handle portion 3 is provided in a state protruding laterally from the side portion of the tool body portion 2 . The switch body 10 is assembled near the bottom of the handle portion 3 (tool body portion side). A motor 4 as a drive source and a screw tightening mechanism (not shown) operated by the rotational power of the electric tool are incorporated in the tool main body 2 .

[0028] The switch body 10 has a switch handle 11 for switching on and off the power circuit of the motor 4 . The switch handle 11 is arranged in a state protruding from the front surface of the handle part 3 . When the user pulls the switch handle 11 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com