Method for repeated grouting of anchor foundation full section of power transmission line tower site group

A technology for transmission lines and repeated grouting, which is used in infrastructure engineering, construction, sheet pile walls, etc., can solve problems such as difficulty in improving the labor conditions of construction personnel, difficulty in entering large construction machines, and harsh labor conditions in mountainous areas. The effect of improving the degree of mechanization, avoiding blasting, and reducing construction difficulty and work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

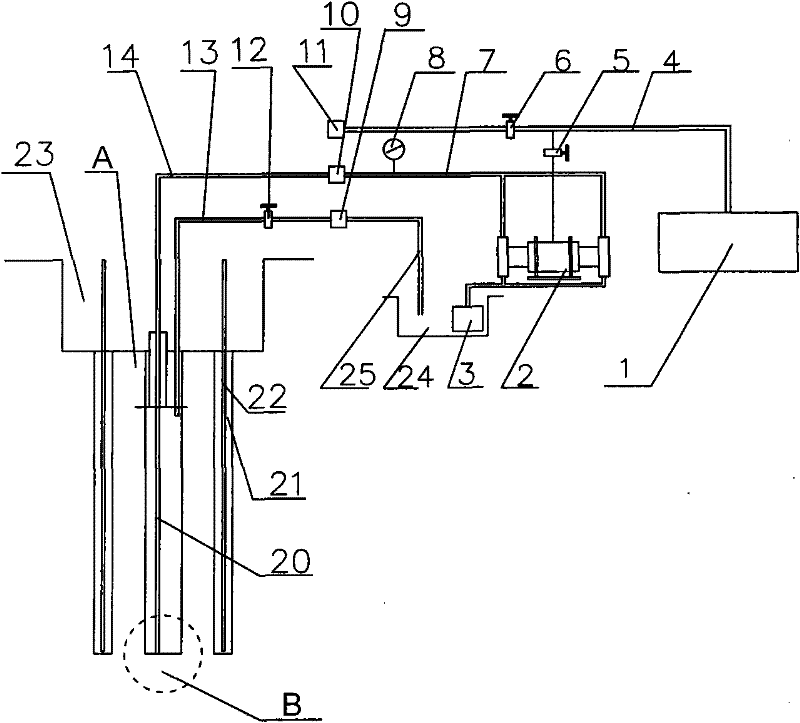

[0031] Below in conjunction with accompanying drawing and specific embodiment this method is described in further detail:

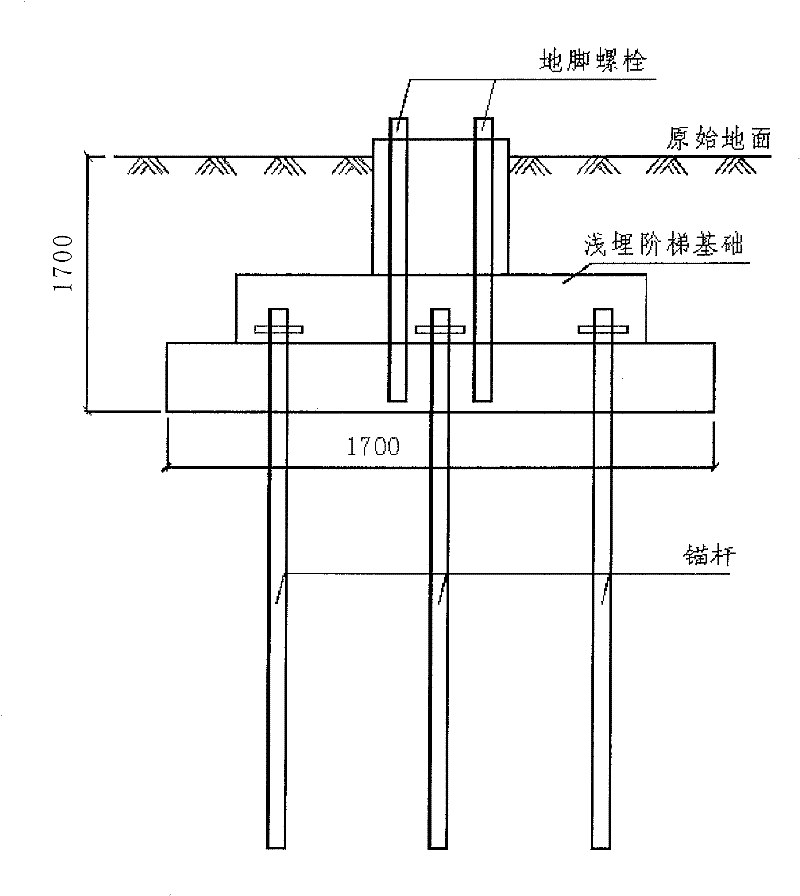

[0032] The method for repeated grouting of the whole section of the transmission line tower foundation group anchor foundation designed by the present invention comprises the following steps:

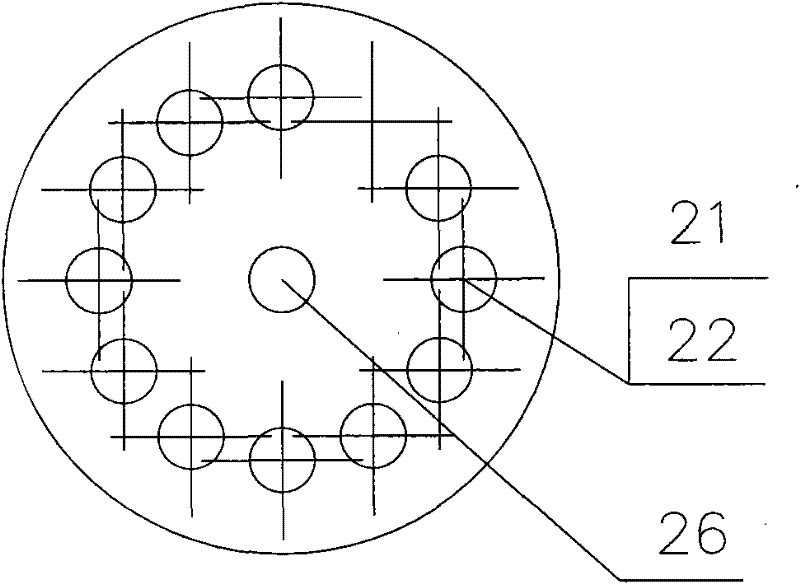

[0033] (1), after the anchor rod 22 is arranged in the anchor rod body 21 in the foundation pit around the grouting hole, a pressure grouting input pipe is inserted in the grouting hole, and the orifice of the grouting hole is sealed with concrete, and at the same time the seal is pressed The head of the grout pipe and the grout return pipe, after the concrete setting period, start to inject grout into the grout input pipe for the first time;

[0034] (2) When the grout return pipe starts to return grout during the grouting process, when the grout is diluted, add cement to the grout return tank to adjust the grout concentration, control the grout concentration and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com