Stevia rebaudiana residue dehydrator

A technology of stevia residue and dehydrator, which is applied to dryers, dry solid materials, lighting and heating equipment, etc. It can solve the problems of not meeting the dehydration requirements of stevia residue, poor dehydration effect, and high manufacturing cost, and achieve dehydration Good effect, smooth discharge and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific content of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

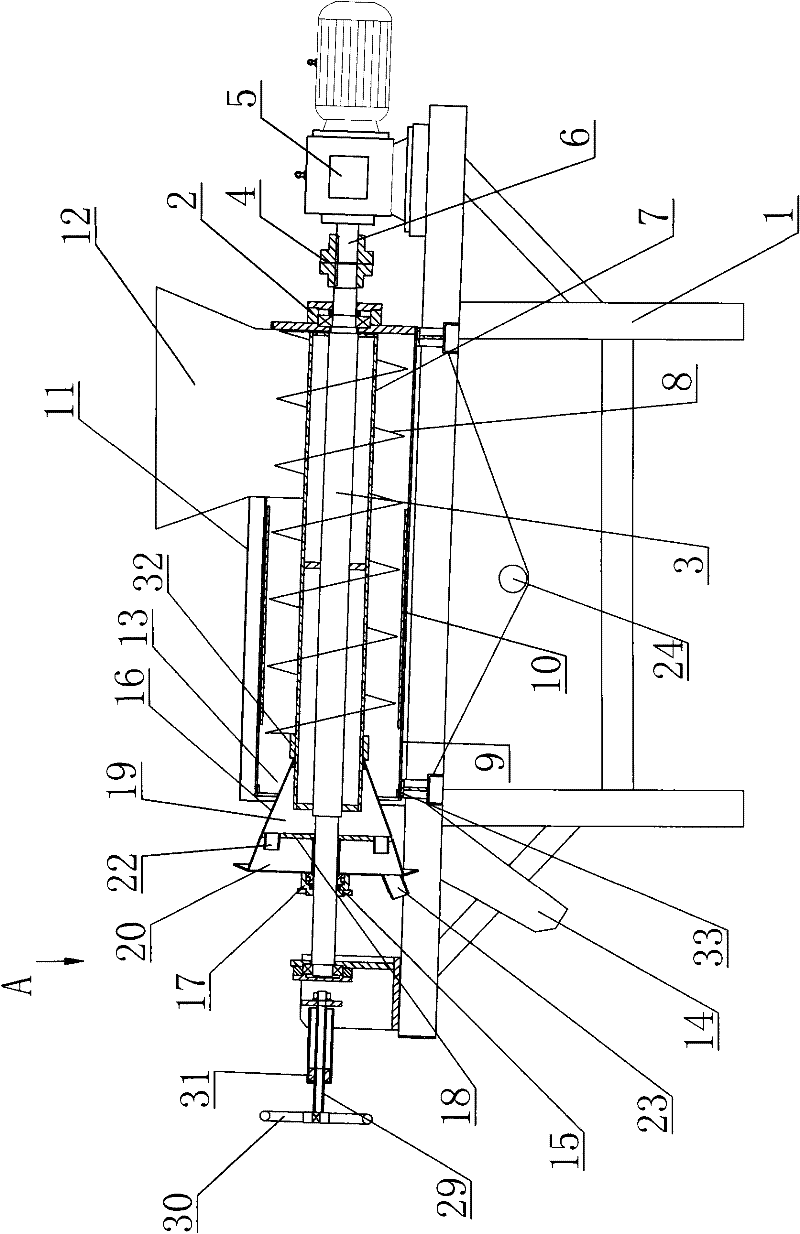

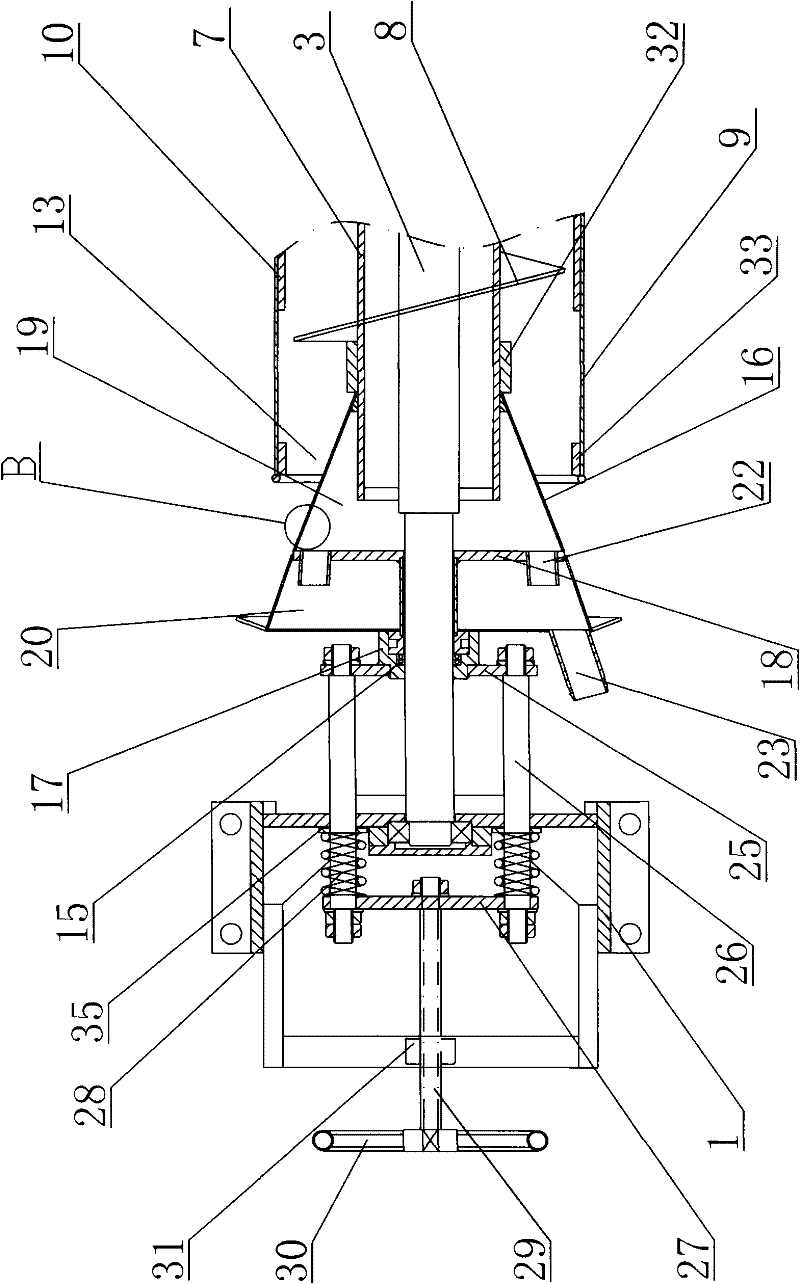

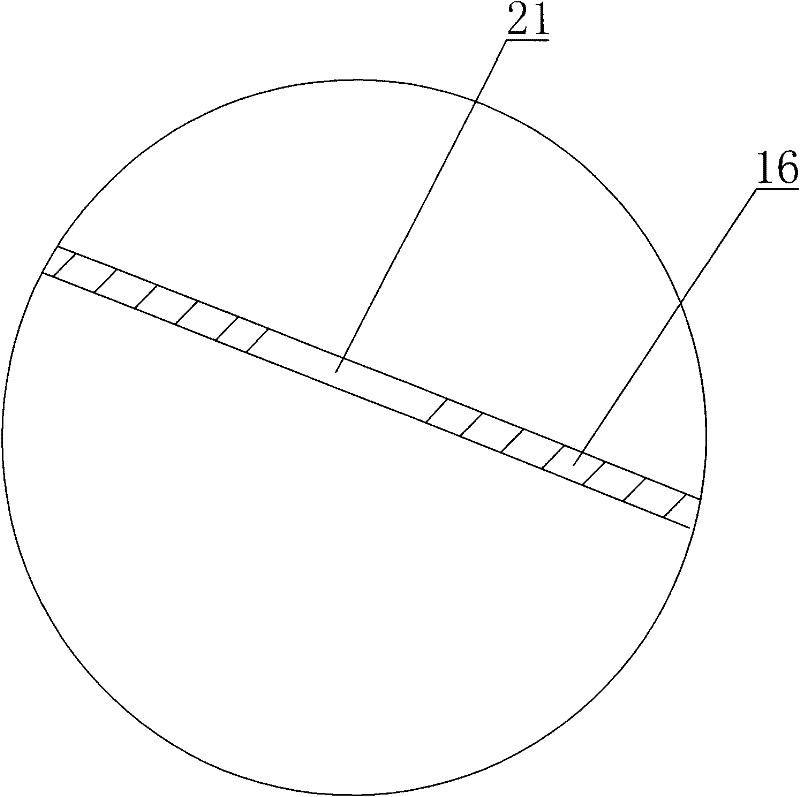

[0016] like figure 1 , figure 2 As shown, the stevia slag dehydrator includes: a frame 1, a main bearing seat 2 is respectively provided on both ends of the frame 1, a main shaft 3 is arranged on the frame 1 through the main bearing seat 2, and one end of the main shaft 3 passes through The coupling 4 is connected with the rotating shaft 6 of the reducer 5, the reducer 5 is fixedly arranged on one end of the frame 1, and the main shaft 3 is fixedly provided with a rotating blade reinforced barrel shaft 7, which is evenly arranged on the rotating blade reinforced barrel shaft 7. A rotating blade 8 is provided, a cylinder 9 is arranged on the outer side of the rotating blade 8, a certain gap is left between the rotating blade 8 and the cylinder 9, and a number of permeable holes are evenly arranged on the cylinder 9. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com