Dehydration control method and washing machine for multi-tubular washing machine

A control method and technology for washing machines, which are applied to control devices of washing machines, other washing machines, washing devices, etc., can solve the problems of small modification work and large amplitude, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

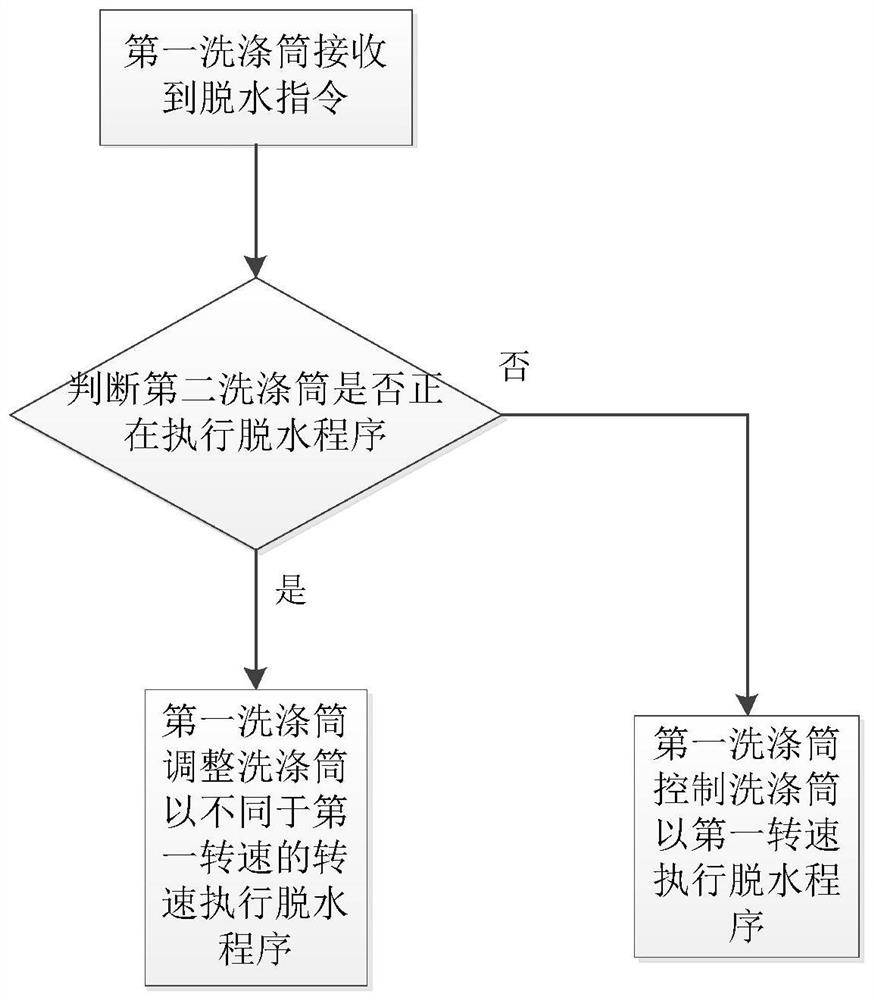

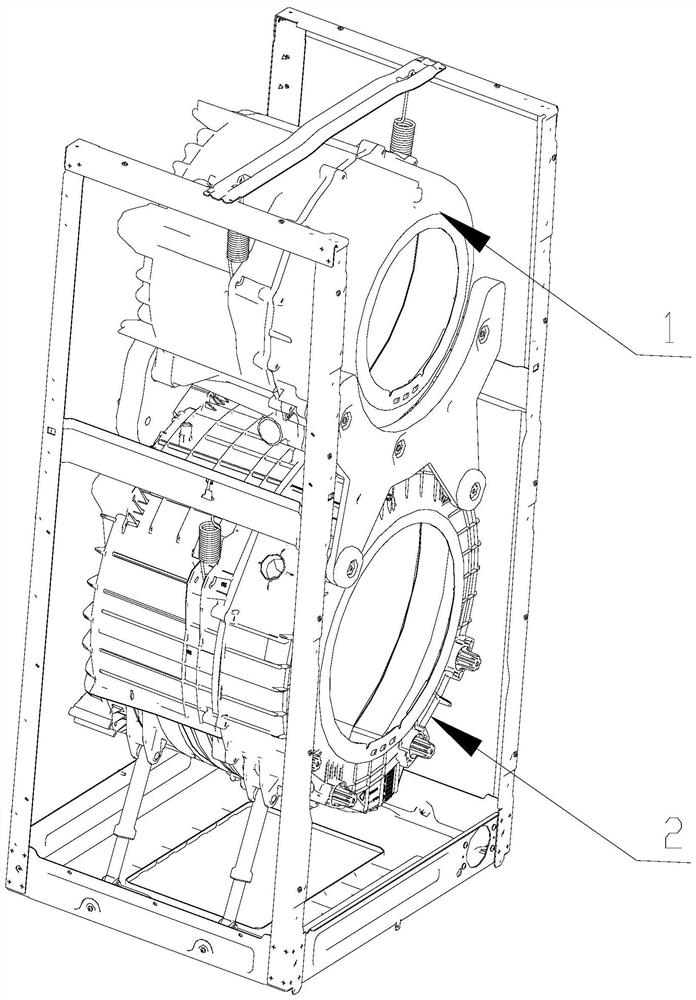

[0039] Such as figure 1 and figure 2 As shown, this embodiment discloses a dehydration control method for a multi-tubular washing machine. The washing machine of this embodiment includes a first washing tub 1, a second washing tub 2 and a control system. When the first washing tub 1 and the second washing tub 2 run dehydration programs at the same time, the control system adjusts the first washing tub 1 and / or the second washing tub. Second, the rotating speed of the washing drum 2 reduces the overall amplitude when the washing machine dehydrates.

[0040] In this embodiment, each washing drum has a plurality of different speed gears corresponding to different speeds, and these speed gears include 600 rpm, or 800 rpm, or 1200 rpm, or 1500 rpm. rpm.

[0041] Before the first washing tub executes the dehydration program, it is judged whether the second washing tub is performing the dehydration program; if not, the first washing tub controls the washing tub to perform the deh...

Embodiment 2

[0047] This embodiment is a supplement to Embodiment 1. In this embodiment, the second rotating speed is adjusted according to the eccentricity of the clothes to be dehydrated in the washing tub in the first washing tub. The second rotating speed and the eccentricity size is negatively correlated. The second rotation speed in this embodiment is no longer simply a certain rotation speed gear lower than the first rotation speed, but a dynamically changing value adjusted according to the eccentricity of the laundry to be dehydrated in the first washing tub in the washing tub. The change of the second rotational speed here is mainly to adapt to the change of the eccentricity in the washing tub, so that the washing tub can operate at the highest possible rotational speed in the range lower than the first rotational speed under the condition that the sloshing amount of the washing tub meets the application requirements. The dehydration is performed at the second rotational speed, so...

Embodiment 3

[0049] This embodiment is a supplement to the above embodiment. In this embodiment, the second rotational speed is adjusted according to the vibration amplitude of the washing machine, and the second rotational speed is negatively correlated with the vibration amplitude. The control of the second rotational speed in this embodiment no longer focuses on parameters such as the washing tub itself or the properties of the clothes, but on the vibration amplitude of the washing machine as a whole. During the dehydration process of the washing machine, in a certain speed range, the higher the rotation speed, the smaller the shaking produced by the washing tub; at the same time, for the power output, the dehydration of the first washing tub and the second washing tub are operated independently Each of the two dehydration processes will generate corresponding vibrations of a certain frequency during the dehydration process. For the overall vibration amplitude of the washing machine, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com