Efficient sludge concentration and dehydration system and dehydration method thereof

A technology of sludge thickening and sludge thickening tank, which is applied in the direction of dehydration/drying/thickened sludge treatment, etc. It can solve the problems that the normal operation of sewage treatment equipment cannot be guaranteed, and achieve the effects of easy connection, reduced resistance, and lower BOD5

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

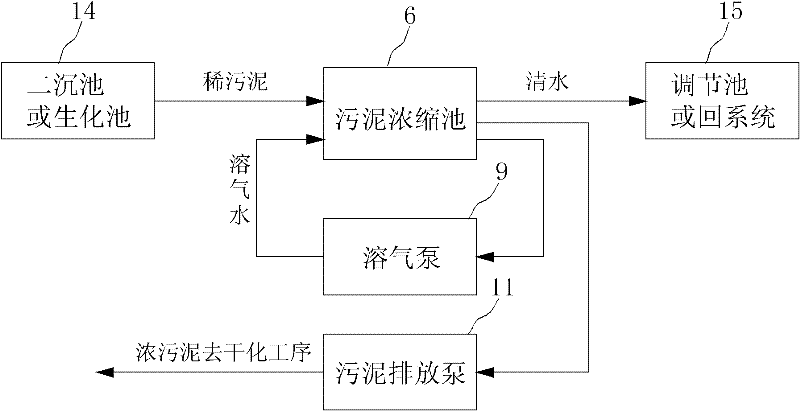

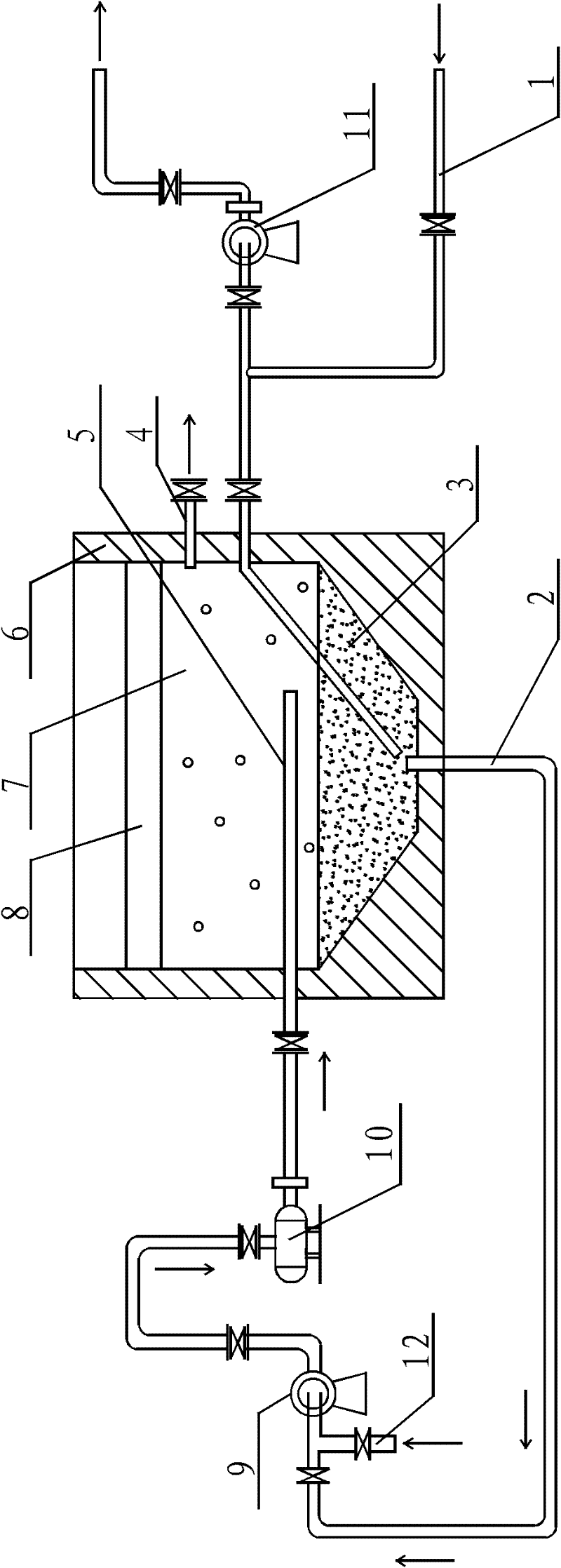

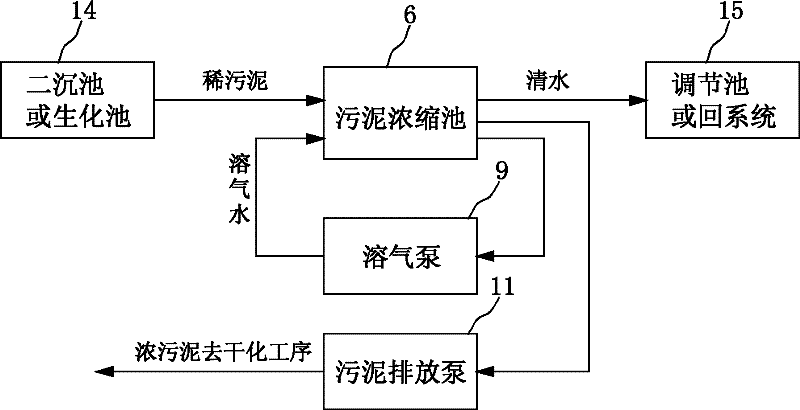

[0030] Such as figure 1 , 2 As shown, the dilute sludge (more than 99.5% water content) discharged from the biochemical tank or the secondary settling tank 14 is lifted to the sludge thickening tank 6 by gravity flow or pump, and after standing for a short time in the sludge thickening tank 6, most of the sludge settles Enter the sedimentation cone bucket 3 at the bottom of the pond. If the mud-water interface in the sludge thickening pond 6 is clear, the lower clear water will be discharged to the regulating pond 15 or transported back to the system. Stop the discharge when the clear water is discharged to relatively turbid. Start the sludge discharge pump 11 to discharge the sludge accumulated in the sedimentation cone 3 without dissolving the gas; when the concentration of the discharged sludge is very thin, stop the discharge. Then start the dissolved air pump 9, open the dissolved air valve, control the amount of dissolved air in the water outlet of the dissolved air pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com