Railway brake shoe

A brake shoe and main body technology, applied in the field of composite material railway brake shoes, can solve the problem of not being able to wait

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

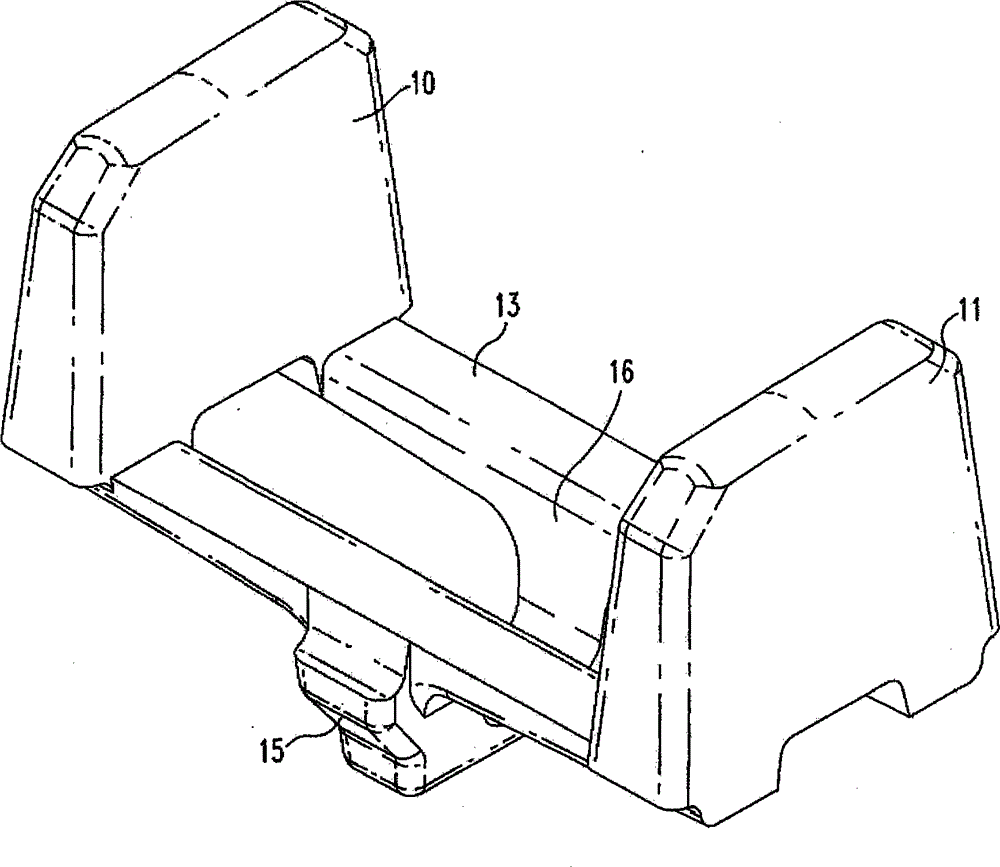

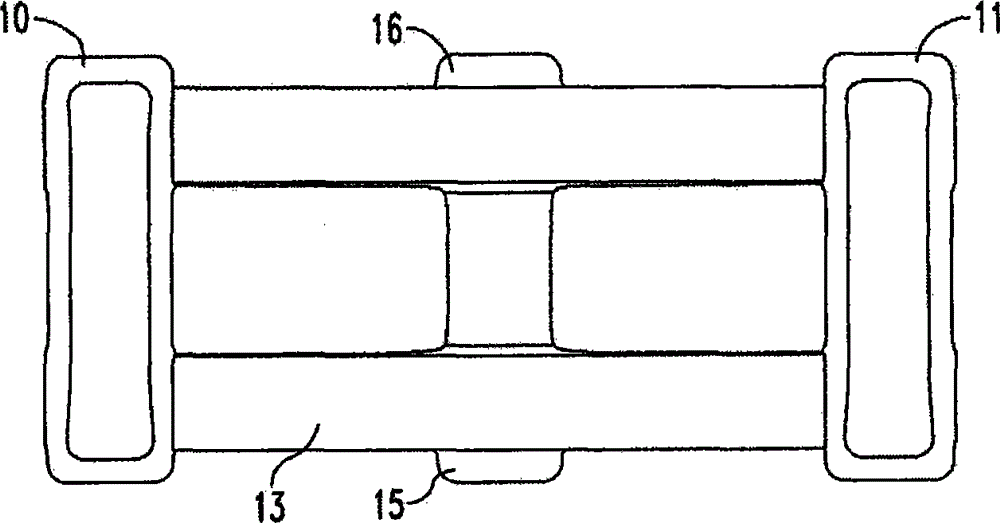

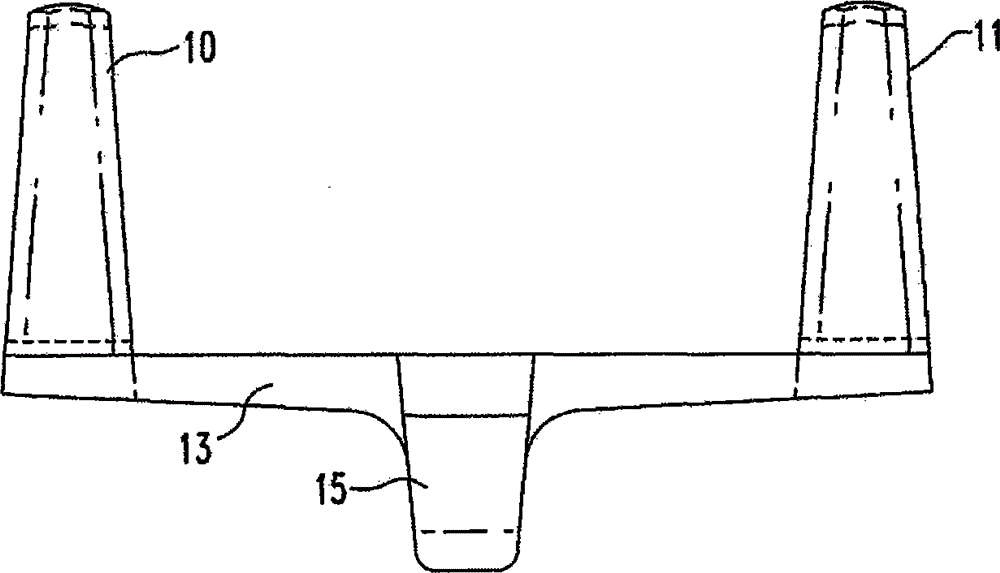

[0018] Refer below Figure 1 to Figure 4 , shows an insert for a brake shoe without a metal backing plate. The brake shoe is defined by a friction surface for applying pressure to the tread of the wheel and an opposing back surface arranged to contact and be secured to the brake shoe carrier. The metal insert 9 comprises two divided bodies 10, 11 having a friction face 12 on the friction surface of the brake shoe. The two separated bodies 10 , 11 extend away from the friction surface 12 .

[0019] A connecting portion 13 extends between the two spaced apart bodies 10 , 11 . The connecting portion 13 has a back face 14 disposed adjacent to the back surface of the brake shoe and providing support for the brake shoe holder. Two substantially parallel radially extending flanges 15 , 16 are integrally formed with the connecting portion 13 . The parallel flanges 15 , 16 are dimensioned to extend beyond the back surface of the brake shoe so as to define a keyway 17 .

[0020] Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com