Infinitely variable transmission device of a drive train of a vehicle

A technology of continuously variable speed and transmission equipment, which is applied to transmission devices, mechanical equipment, belts/chains/gears, etc., which can solve the problems of large structural expenses and high manufacturing costs, and achieve the effect of small structural space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

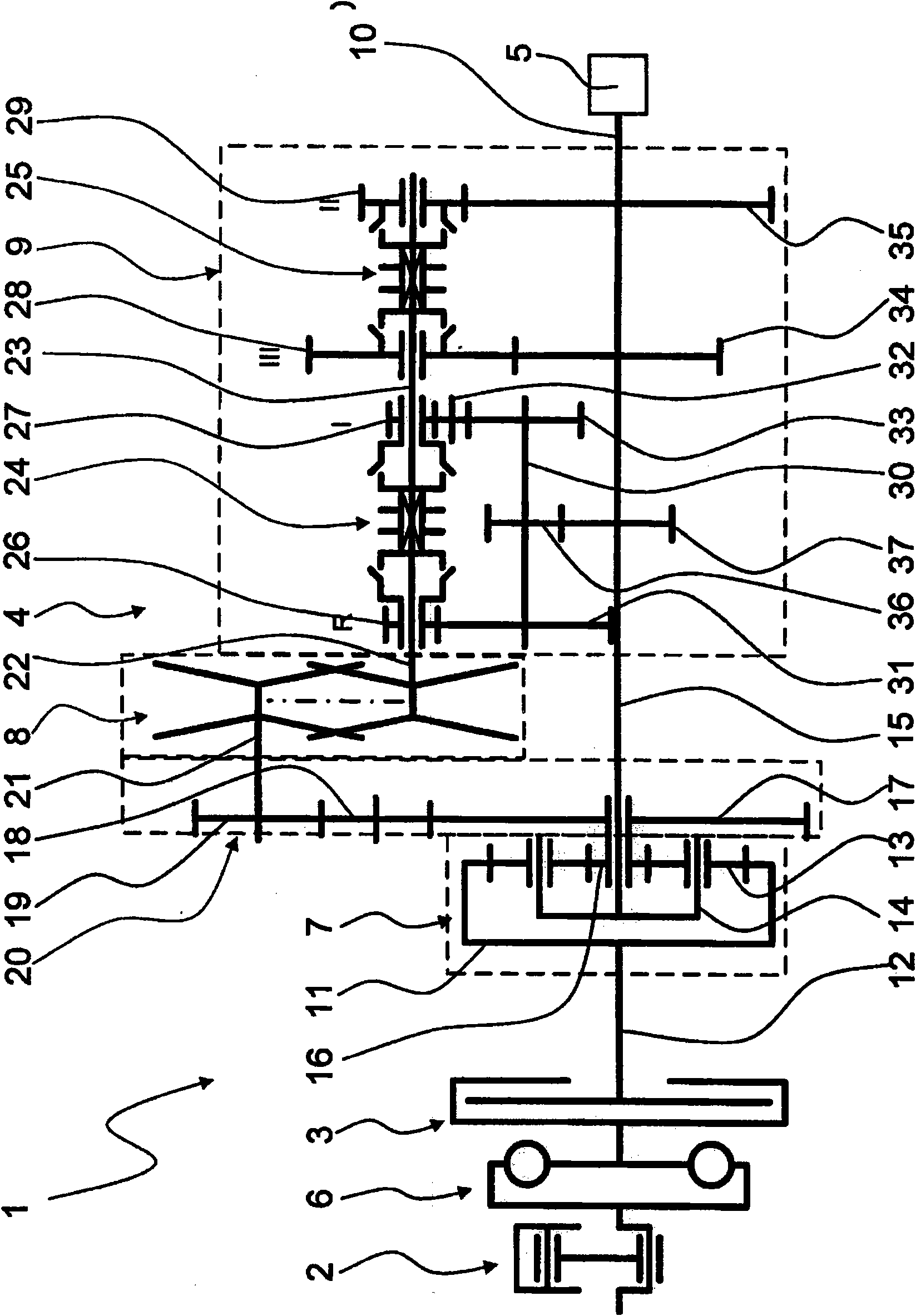

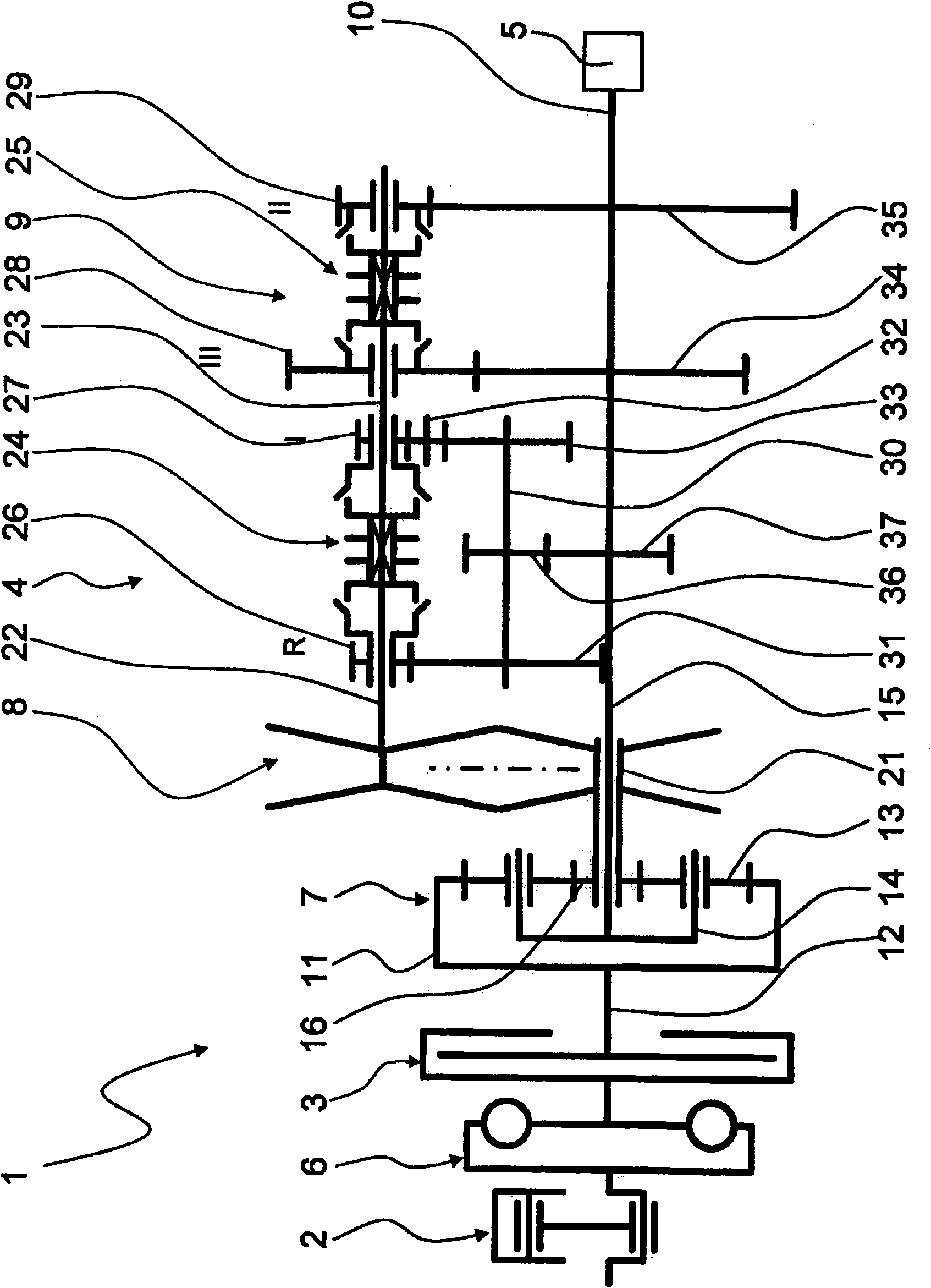

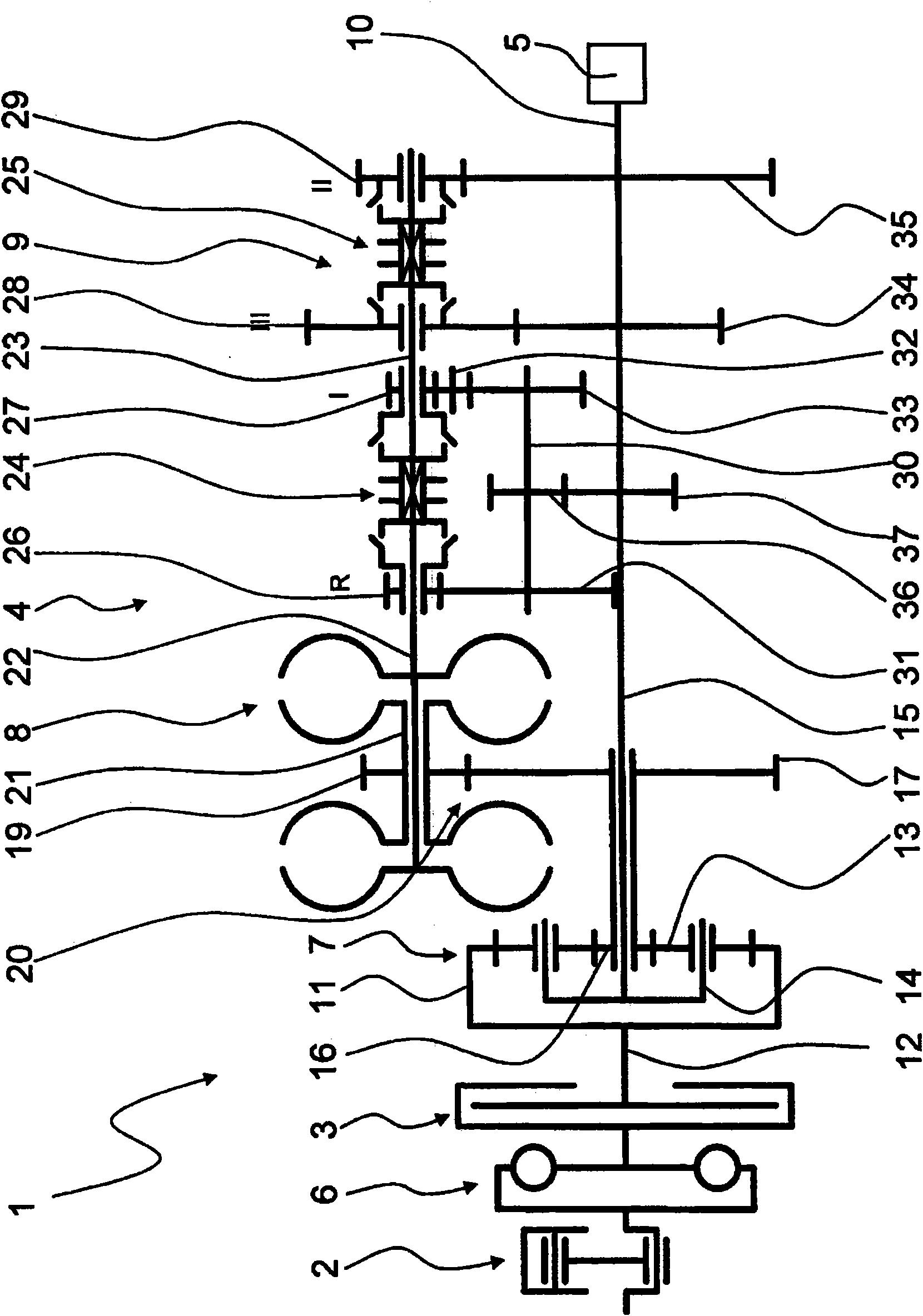

[0028] exist figure 1 1 shows in very schematic form a motor vehicle drive train 1 comprising an engine 2 , a starter 3 , a transmission 4 and an output shaft 5 . A so-called vibration damper 6 is arranged between the engine 2 and the starter 3 , here in the form of a friction clutch, by means of which vibration inhomogeneities of the engine 2 , here in the form of an internal combustion engine, can be damped.

[0029] The transmission device 4 is designed as a continuously variable power-split transmission, which has a planetary gear 7 designed as a negative planetary gear set on the transmission input side and a shifting gear 9 on the transmission output side, wherein the shifting gear The device 9 is arranged between the transmission 8 , here in the form of a belt transmission, and the transmission output 10 or the output shaft 5 of the vehicle drive train 1 .

[0030] The first shaft 11 of the planetary gear 7 configured as a ring gear is connected to the engine 2 via the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com