Modularized adjustable passenger train end wall assembling and welding table

An adjustable and modular technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting delivery time, small quantity, increasing cost, etc., and achieve production potential, simple structure, The effect of saving seats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

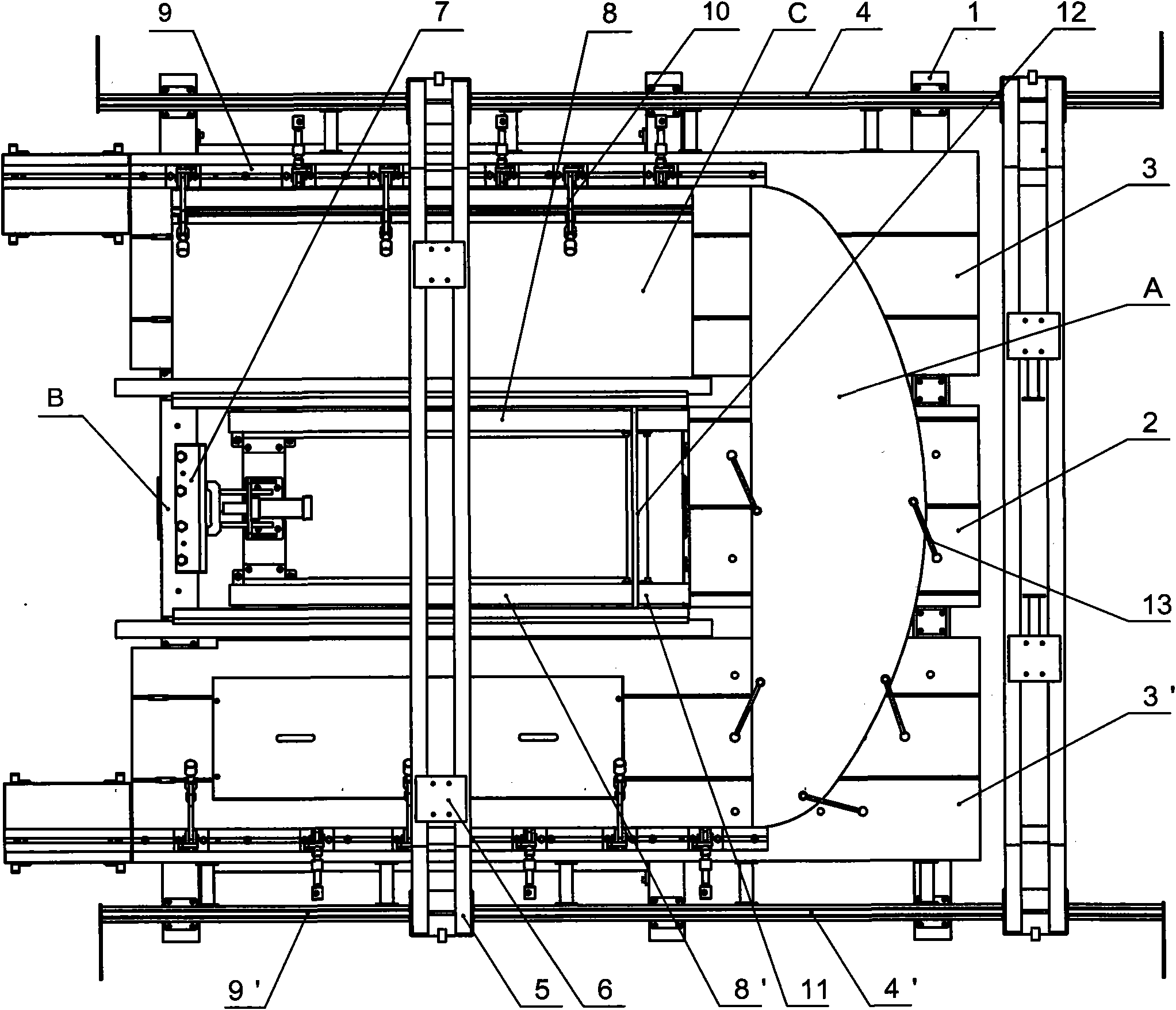

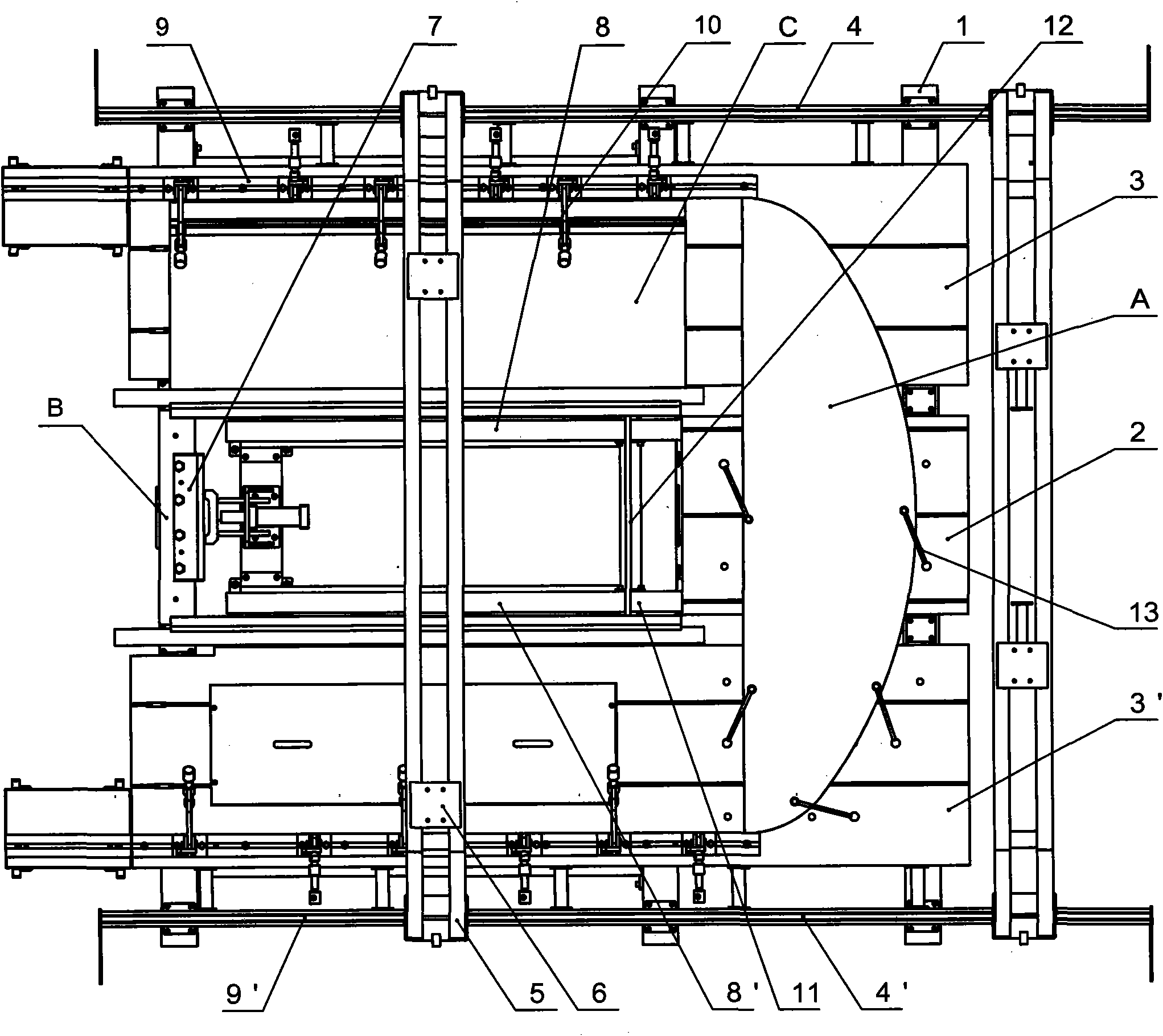

[0015] The modular adjustable passenger car end wall assembly welding tire of the present embodiment, as figure 1 As shown, the modular adjustable passenger car end wall assembly welding tire includes the underframe 1, the short workbench 2 fixed to the underframe 1, the long workbenches 3 and 3' distributed on both sides of the short workbench, and the short workbench 2 Bolts on the bottom frame 1 at the far end are fixed with door sill positioning components 7, bolts on the inside of long workbenches 3 and 3′ are fixed with door frame positioning components 11, and bolts on the bottom frame 1 on the outside of long workbenches 3 and 3′ are fixed with positioning strips 9, 9', the distance between the inner side of positioning bar 9, 9' is equal to the width of the passenger car end wall, and the distance between the door frame positioning composition 11 outer end faces is equal to the door frame width of the passenger car end wall. like figure 1 As shown, in this example, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com