Three-aperture bell mouth for compact spinning

A bell mouth and compact technology, which is applied in the field of compact Siro spinning machine and bell mouth structure, can solve the problems of high power consumption, etc., and achieve the effects of improved production efficiency, good evenness and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

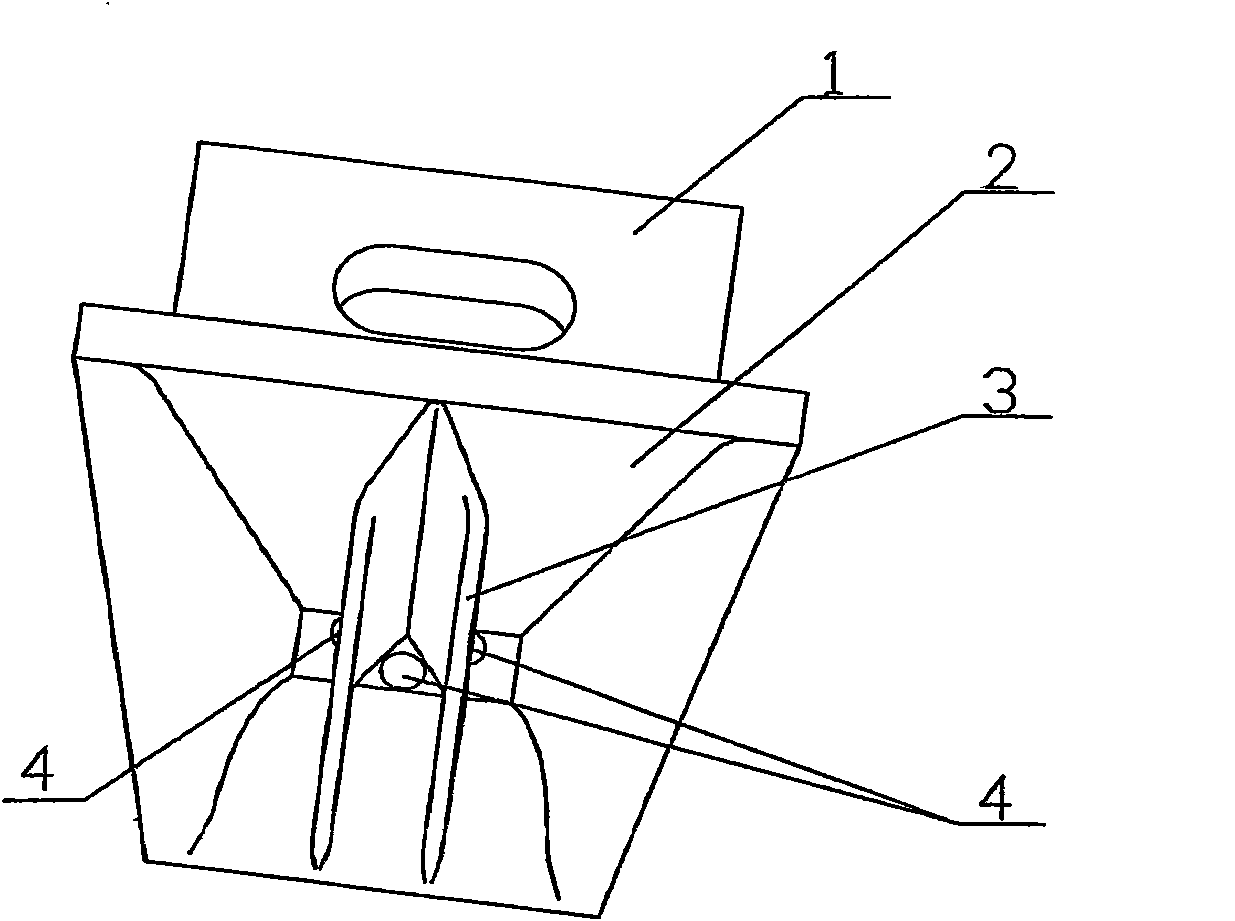

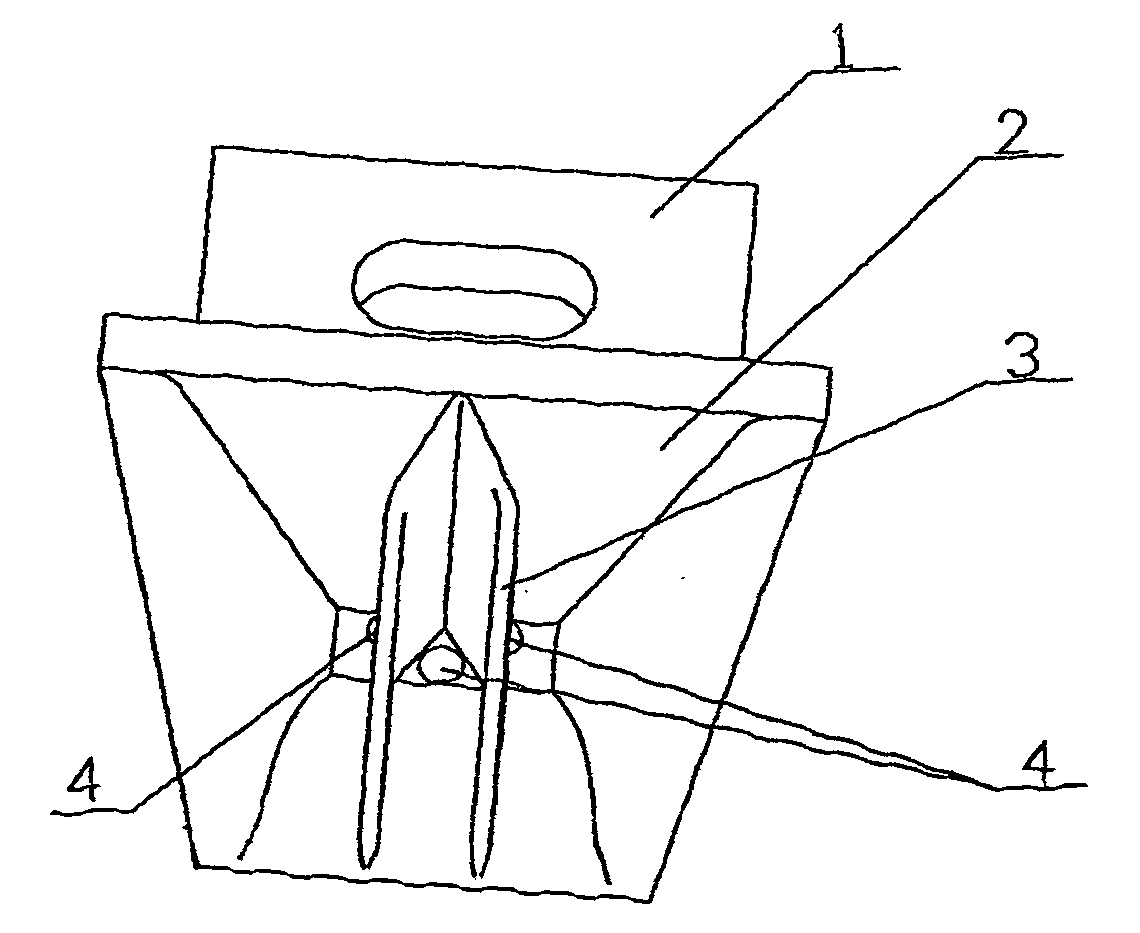

[0014] see figure 1 , the present invention relates to a three-hole bell mouth for compact spinning. The three-hole bell mouth is a square cone-shaped bell mouth. It is oblique in front, and three yarn holes 4 are arranged at the lower bottom, and two partitions 3 are arranged between the three yarn holes 4, and the two partitions 3 are arranged in an inverted "V" shape, and the three yarn holes are just arranged. Holes 4 are spaced apart.

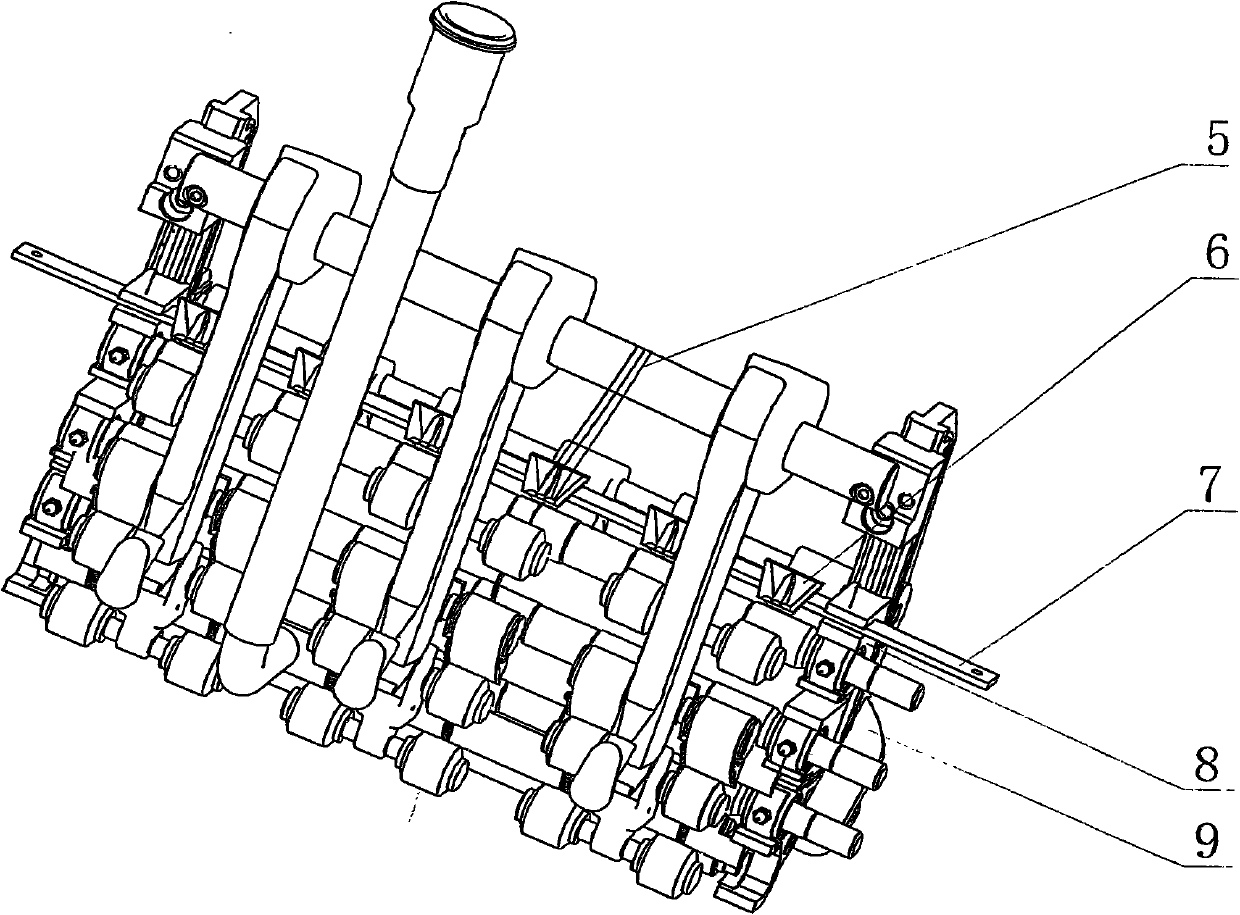

[0015] The rear side of the main body 2 of the square cone-shaped bell mouth is fixedly provided with a rear fixing plate 1, and the three-hole bell mouth 2 is fixed on the flat iron 3 by screws through the rear fixing plate 1, and the flat iron 3 is placed on the roller of the spinning frame on the rear roller sliding seat of the seat. The three rovings 1 respectively pass through the three yarn holes of the three-hole bell mouth 2, and pass through the compact spinning device of the spinning frame to form strands.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com