Method and device for laying unidirectional fiber layer on mobile bracket and method for producing multi axial cloth

A unidirectional fiber, multi-axial technology, applied in the direction of non-woven fabrics, textiles and papermaking, flat warp knitting machines, etc., can solve the decisive obstacle of the storage unit assembly time and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

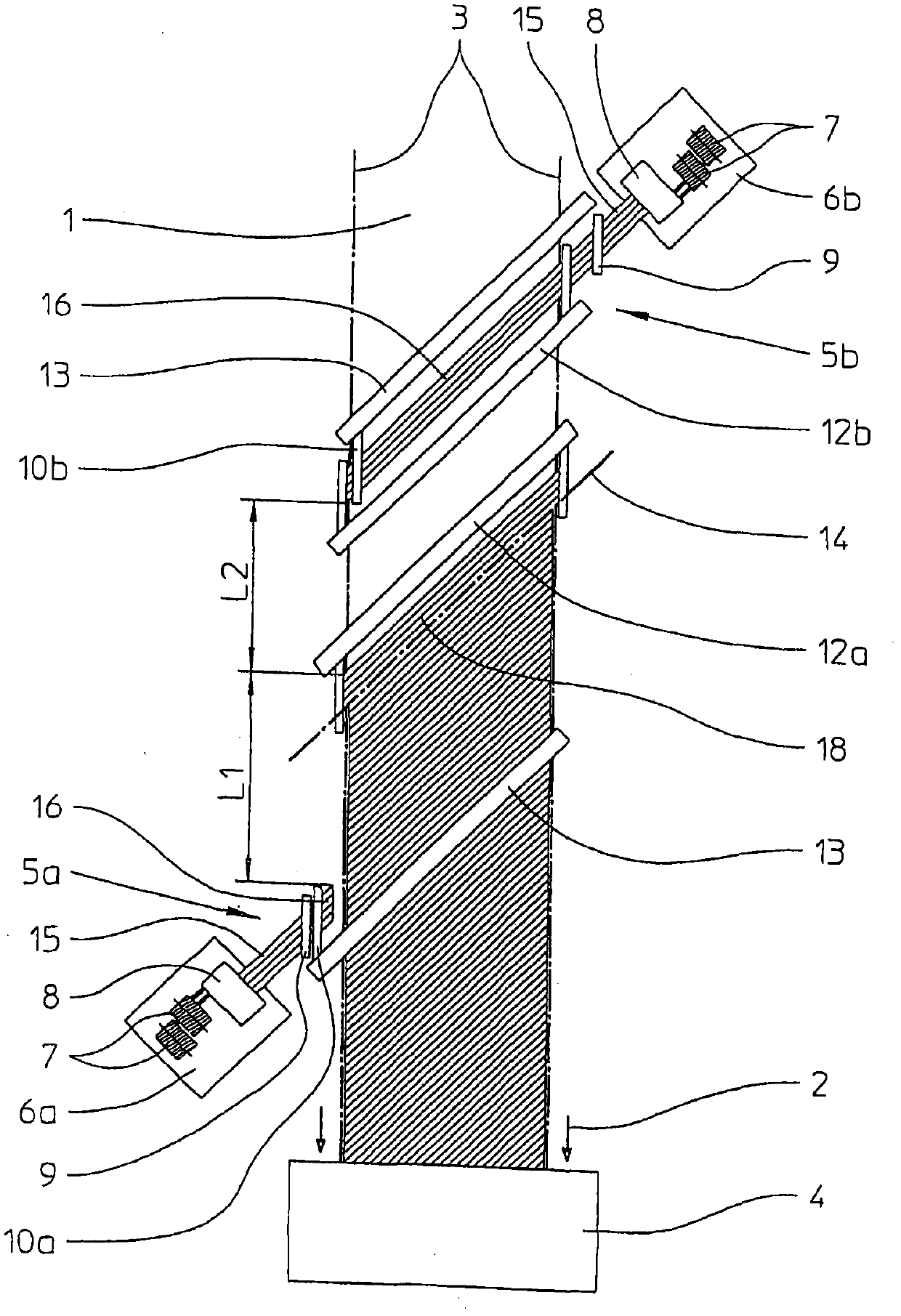

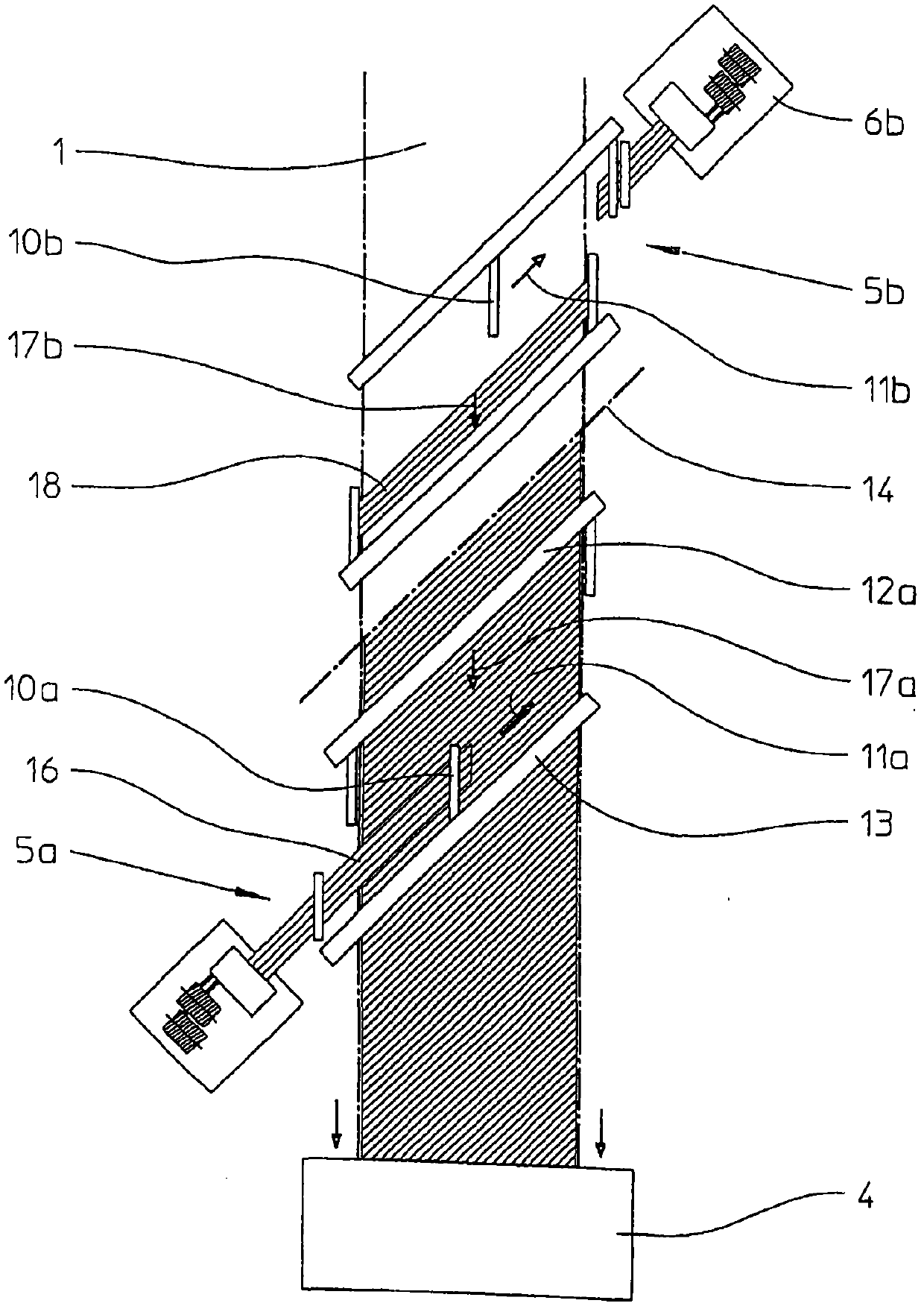

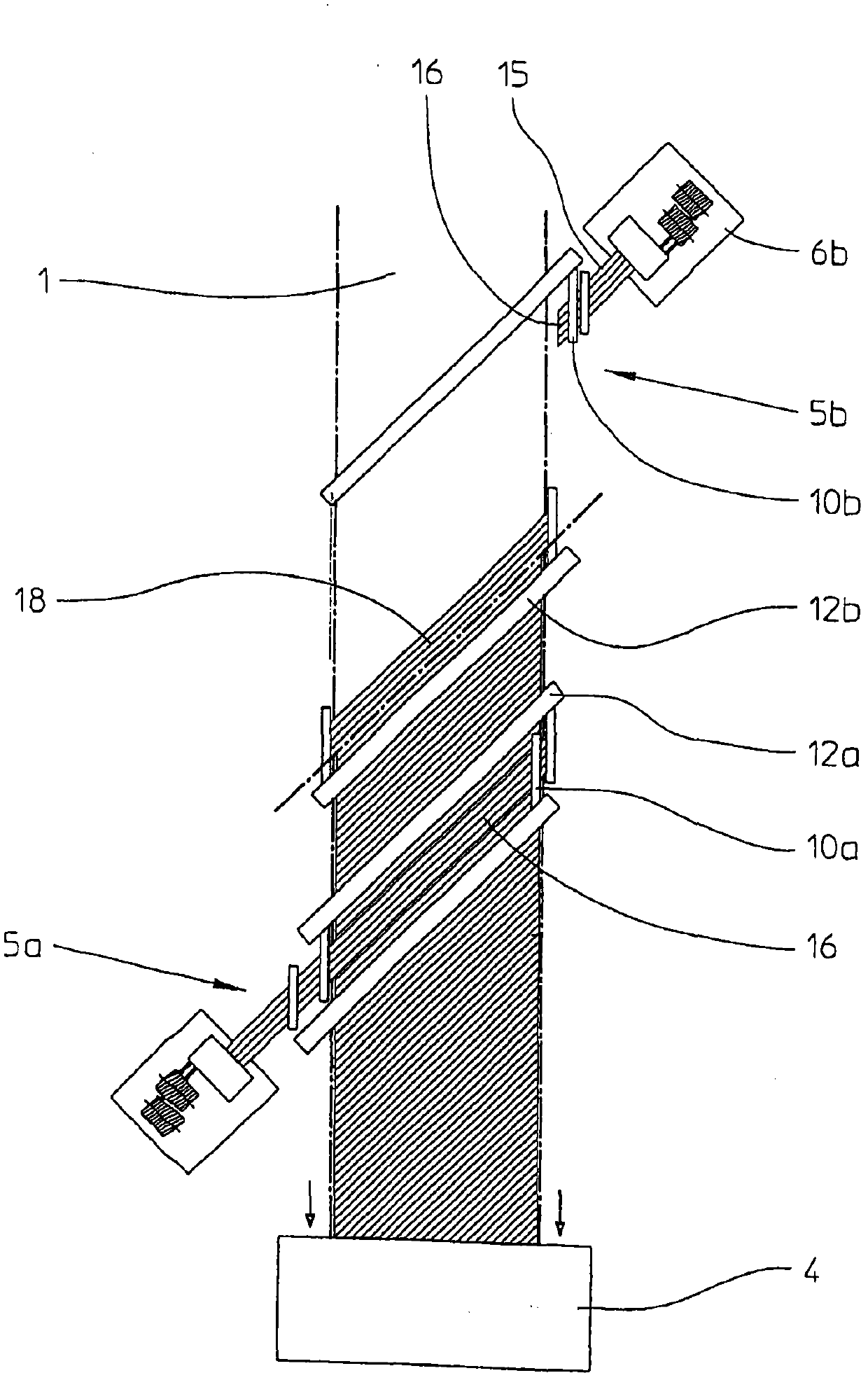

[0036] figure 1 A top view of a first embodiment of the invention is shown. figure 1 And the following figures are only schematic diagrams, which should show important parts. according to figure 1 Place the unidirectional fiber layer onto support 1. Carriage 1 moves in direction 2 , ie in the illustration from top to bottom. The carrier 1 can generally be formed by two conveyor chains 3 , between which the individual sections 18 are clamped in clamping devices (not shown) and thus also supported. The next processing station is indicated with reference numeral 4 . For example, the reference numeral 4 may designate a bobbin on which the finished unidirectional fiber layer is wound in this respect. However, the reference numeral 4 can also designate the next section supply station, in which, for example, a next unidirectional fiber layer is laid on an already existing fiber layer. if in figure 1 The unidirectional fiber layer shown in is the uppermost and last fiber layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com