Electric telescopic pipe

An electric telescopic and inner tube technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of poor axial load-bearing capacity, loose inner tube, poor transmission stability and structural reliability, etc., to achieve The effect of good reliability and stability and improved axial load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

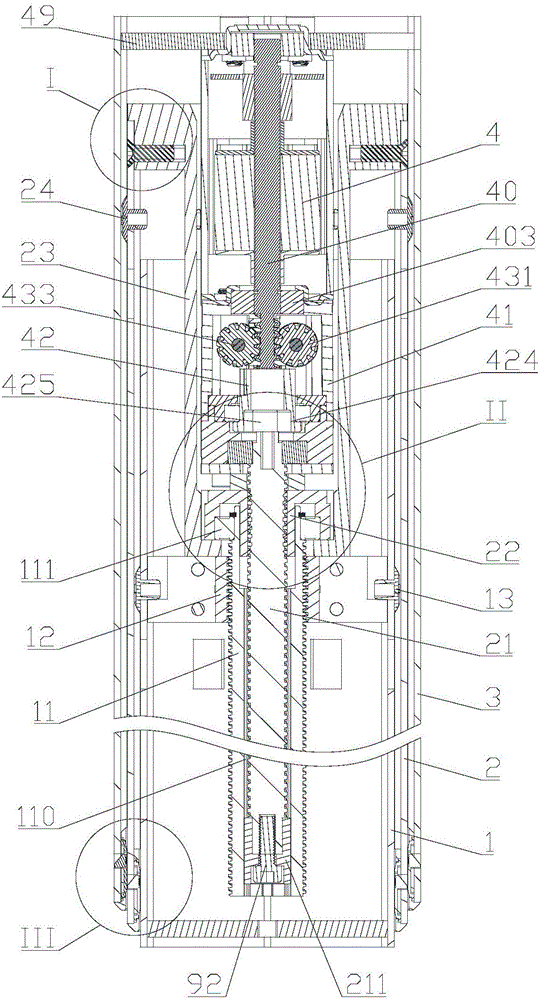

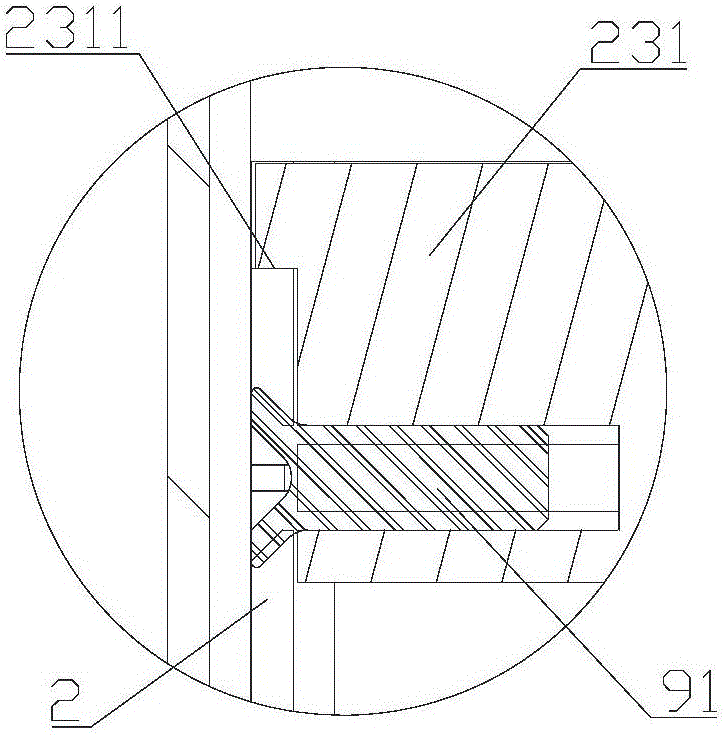

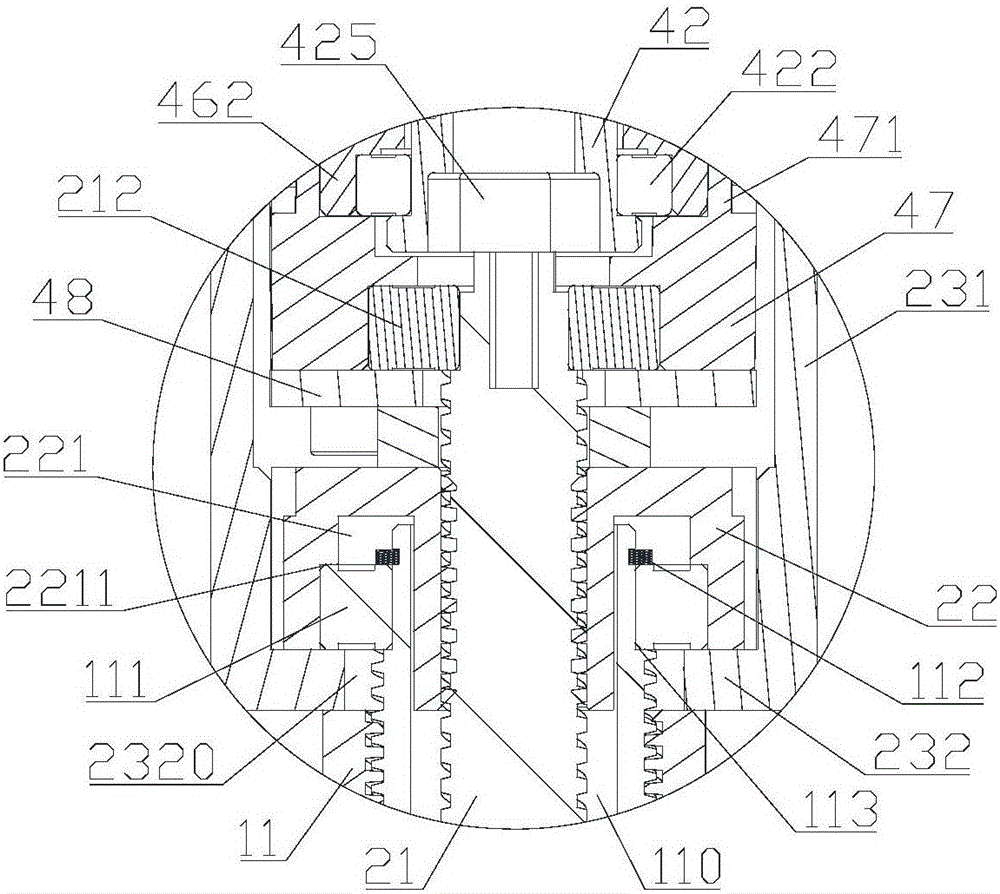

[0027] Such as figure 1 Shown is an embodiment of the present invention, an electric telescopic tube, including an inner tube 1, a middle tube 2 and an outer tube 3, the front end of the inner tube 1 is inserted into the middle tube 2, and the front end of the middle tube 2 is inserted into the outer tube 3 , the front end of the outer tube 3 is provided with a drive device, the middle tube 2 is provided with a first linkage assembly, the first linkage assembly includes a first screw 21 and a first nut 22 that are engaged with each other, and the front end of the first screw 21 is Connected with the driving device, the first nut 22 is fixedly connected with the middle tube 2, and the inner tube 1 is provided with a second linkage assembly, the second linkage assembly includes a second screw rod 11 and a second nut 12 that are engaged with each other, and the second screw rod 11 rotates synchronously with the first screw 21 , the second screw 11 is axially positioned relative t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com