Dynamic pressure air bearing

A technology of dynamic pressure air bearings and dynamic pressure generating grooves, which is applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of easy influence of lubricating gas, blockage of bearing air intake, and decrease of load capacity, etc., and achieve compact structure, Stable load capacity and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

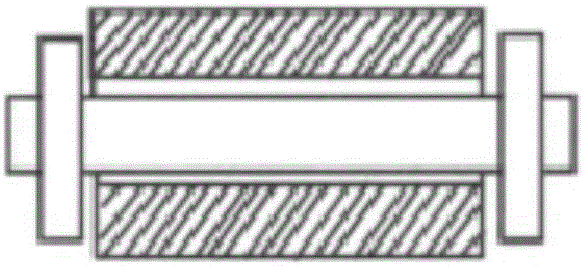

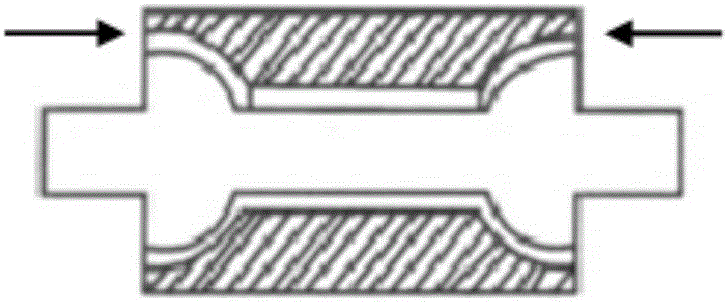

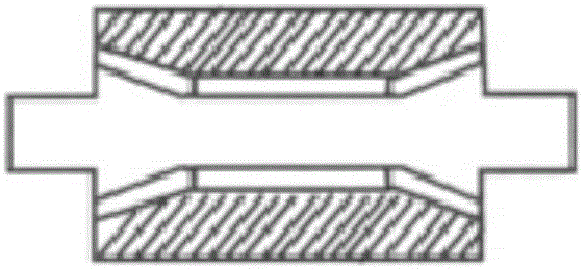

[0026] see Figure 2 to Figure 6 , the present invention provides a dynamic pressure air bearing, comprising: at least one stator 2; a rotor 1, the interior of the rotor 1 is hollow, and the rotor is rotatably sleeved on the at least one stator 2, A dynamic pressure generating groove 6 is formed on the outer peripheral surface of each stator 2 or the inner peripheral surface of a part of the rotor opposite to each stator; an air cavity 7 is defined by another part of the rotor 1 The air cavity is filled with lubricating gas, and when the rotor rotates, lubricating gas is supplied to the dynamic pressure generating groove 6 to generate dynamic pressure in the lubricating gas in the dynamic pressure generating groove.

[0027] The tradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com