Low-axial-movement motor

A technology of axial movement and bearings, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as locking, and achieve the effects of reducing axial movement, increasing rigidity, and improving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

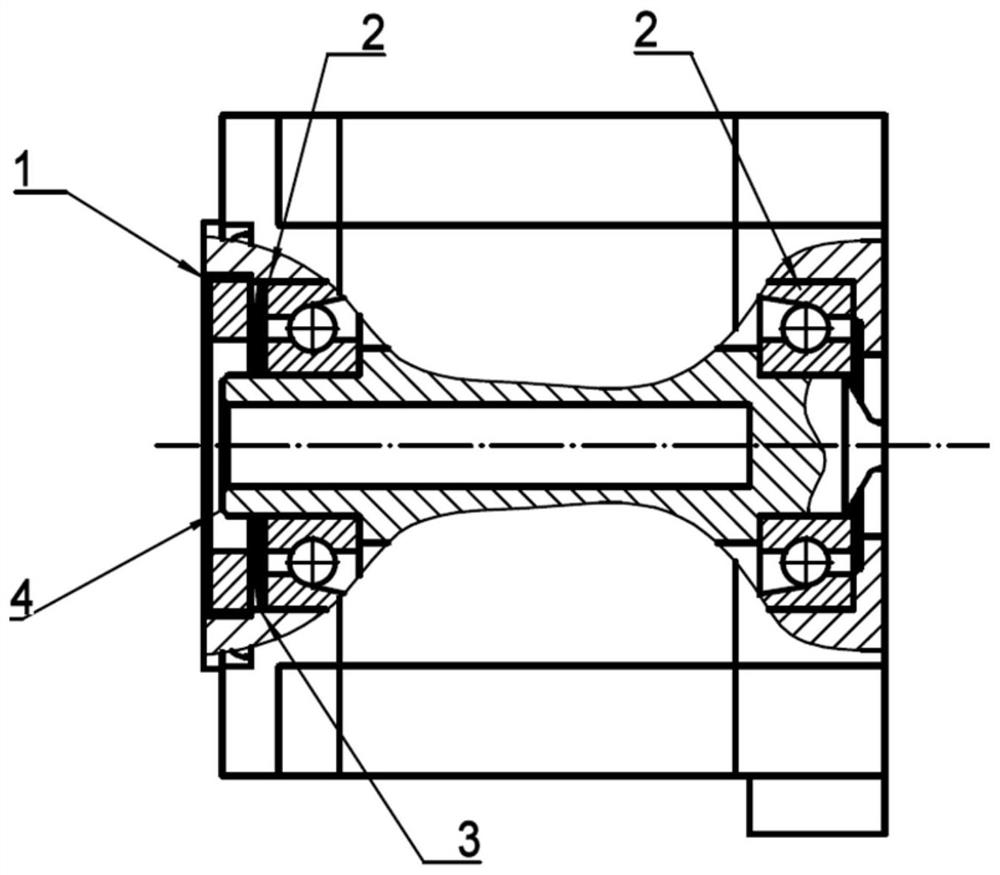

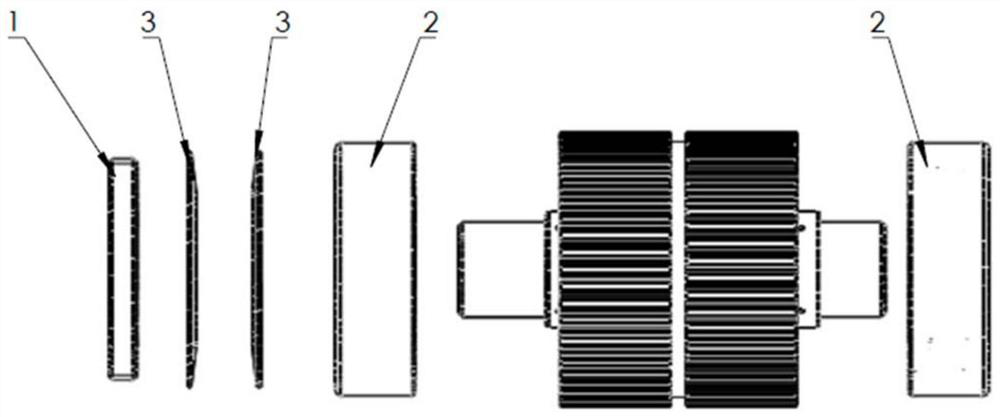

[0039] like Figure 3-4 As shown, take NEMA23 motor as an example: Angular contact bearings are selected according to the size of NEMA23 series motors, and the inner and outer diameters are φ12mm and φ28mm respectively. According to the size of the existing inner and outer rings of the bearing, find a disc washer with a suitable size, so that the disc washer acts on the outer ring of the bearing. The angular contact bearings are located face-to-face at the front and rear ends of the motor, and the butterfly springs are located back-to-back in front of the angular contact bearings and locking blocks at the front of the motor. The setting of the preload is 70-100mN·m. After the assembly is completed, adjust the locking block to an appropriate preload. If the preload is less than the recommended value, the bearing cannot reach the ideal preload state. If the preload is larger than the recommended value, the output torque of the motor will be reduced, resulting in motor failure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com