Axial moving device of intermediate rolls

A technology of axial movement and intermediate roll, which is applied in the direction of rolling mill control device, keeping roll equipment in an effective state, metal rolling, etc. It can solve the problems of high hydraulic control system requirements, damaged rolls, and inability to move rolls, etc., to achieve improvement The ability to control the shape of the plate, improve the effect of impact, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

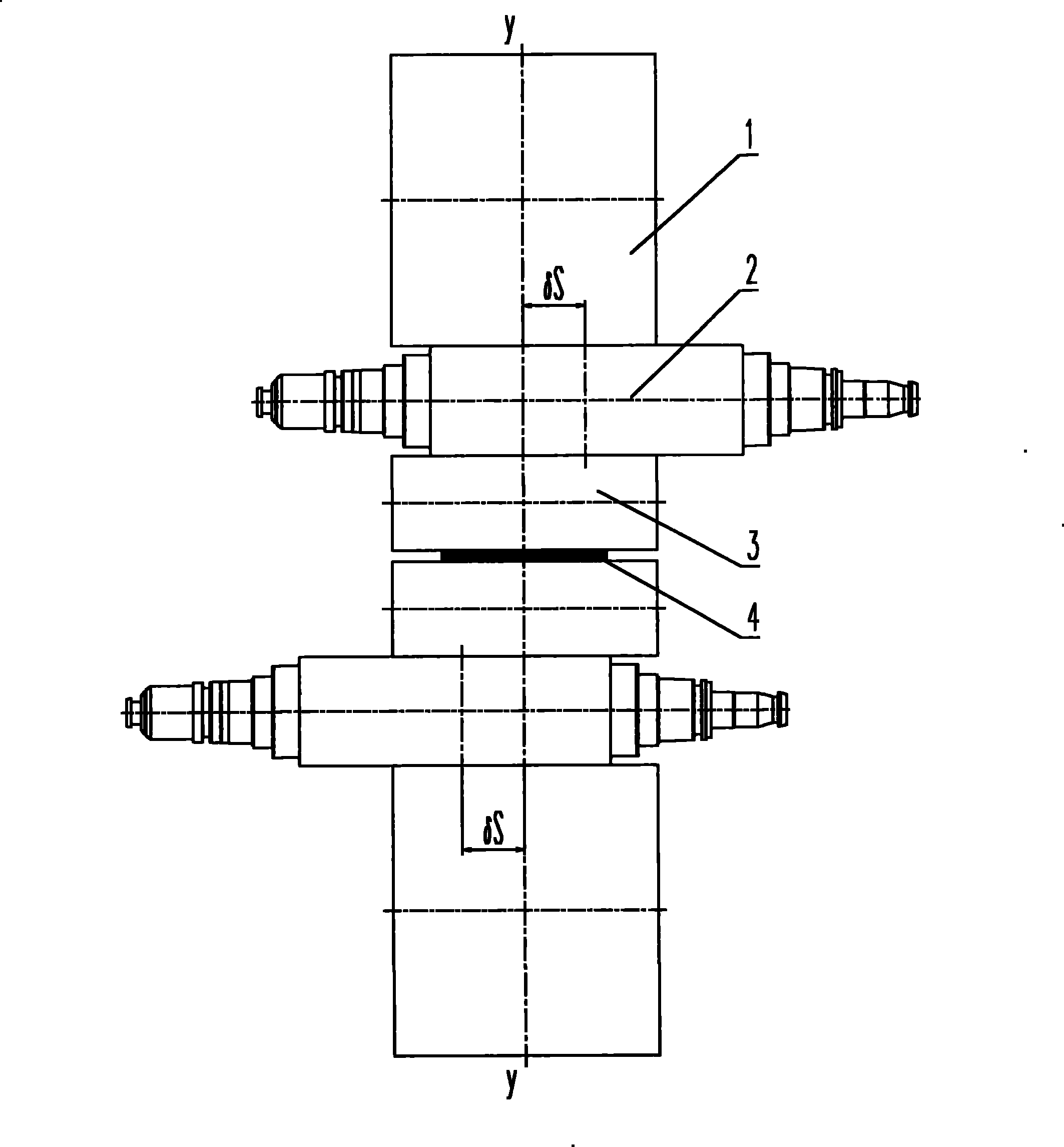

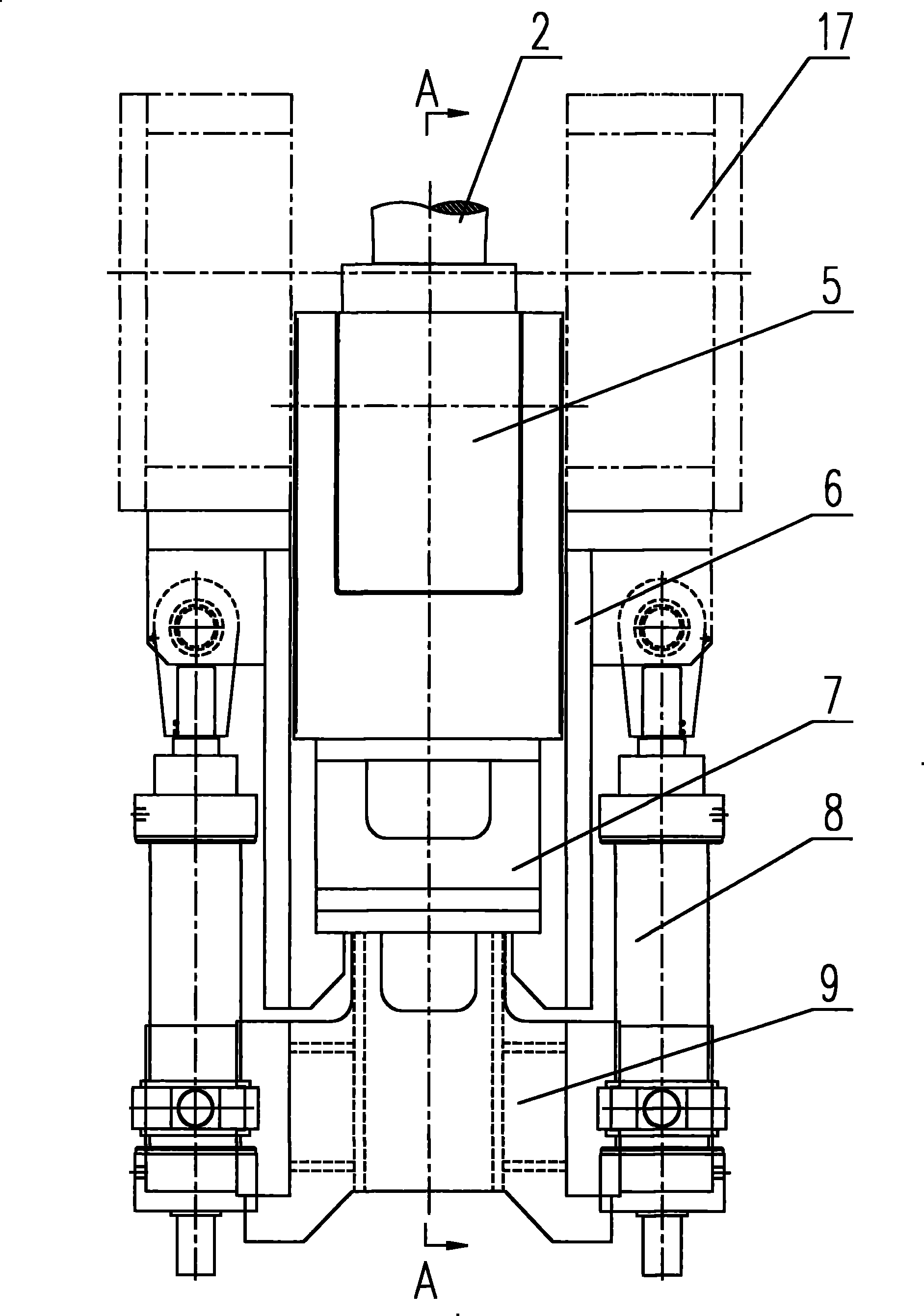

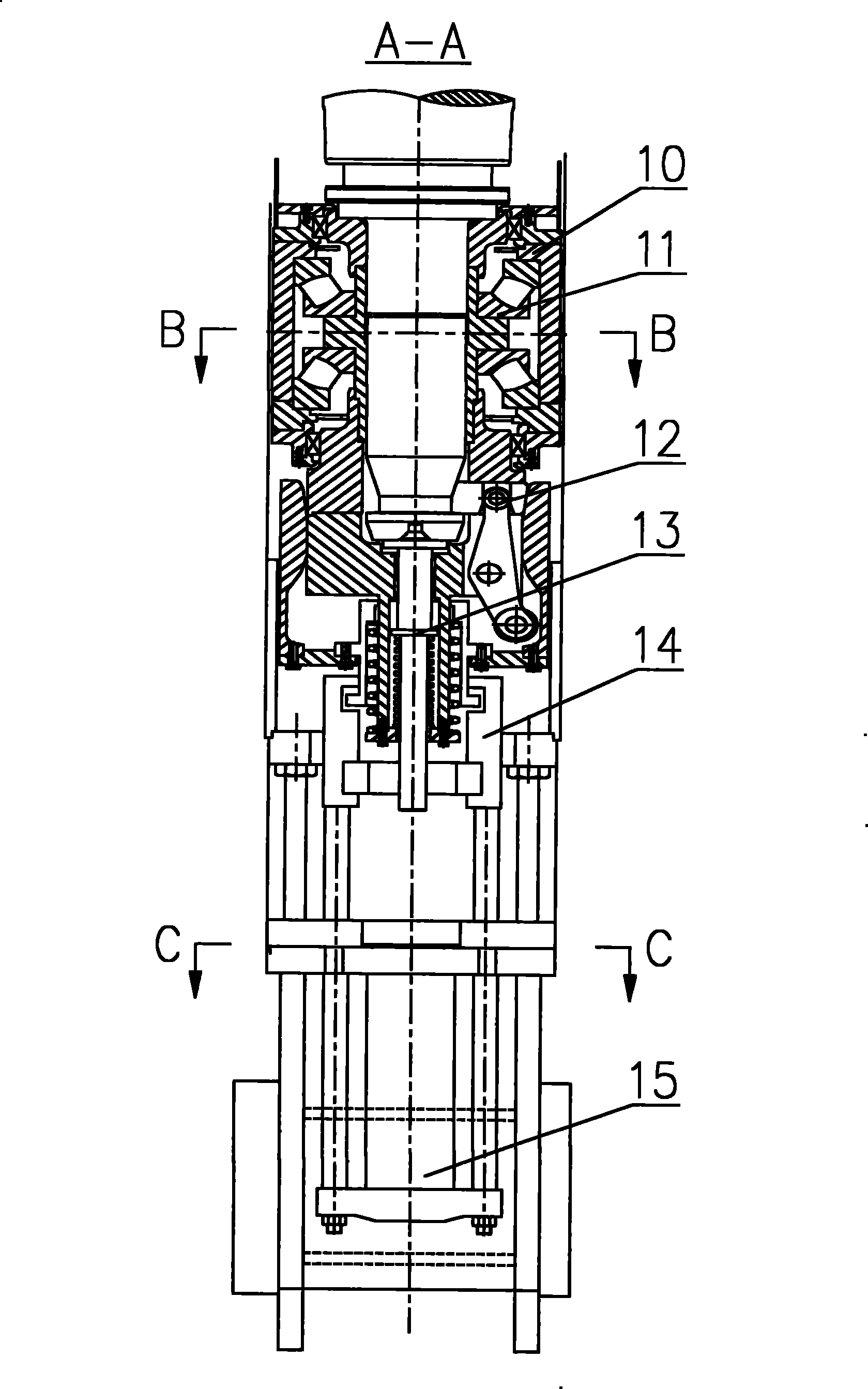

[0021] According to accompanying drawing, the present invention is further described as follows:

[0022] The intermediate roll 2 is installed between the backup roll 1 and the intermediate work roll 3, the rolled strip 4 is between the work rolls 3, the support 6 is a support frame structure, and is installed on the bending block 17 of the rolling mill; the sliding seat 5, the axial The mobile hydraulic cylinder 8 and the tail connection seat 9 are installed on the support 6, wherein the sliding seat 5 is installed on the front of the support 6 and connected with the middle roller 2, and the tail connection seat 9 is installed on the rear of the support 6; the axial movement of the hydraulic cylinder 8 One end is connected with the bracket 6, and the other end is connected with the tail connecting seat 9; at the same time, the tail connecting seat 9 is connected with the sliding seat 5 through the connecting frame 7; the bearing seat 10 is installed in the sliding seat 5; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com