Bearing arrangement

A bearing configuration and bearing technology, which is applied to bearings, bearing cooling, shafts and bearings, etc., can solve problems such as shortening service life and increasing thrust bearing load, and achieves the effect of high load capacity and high axial load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

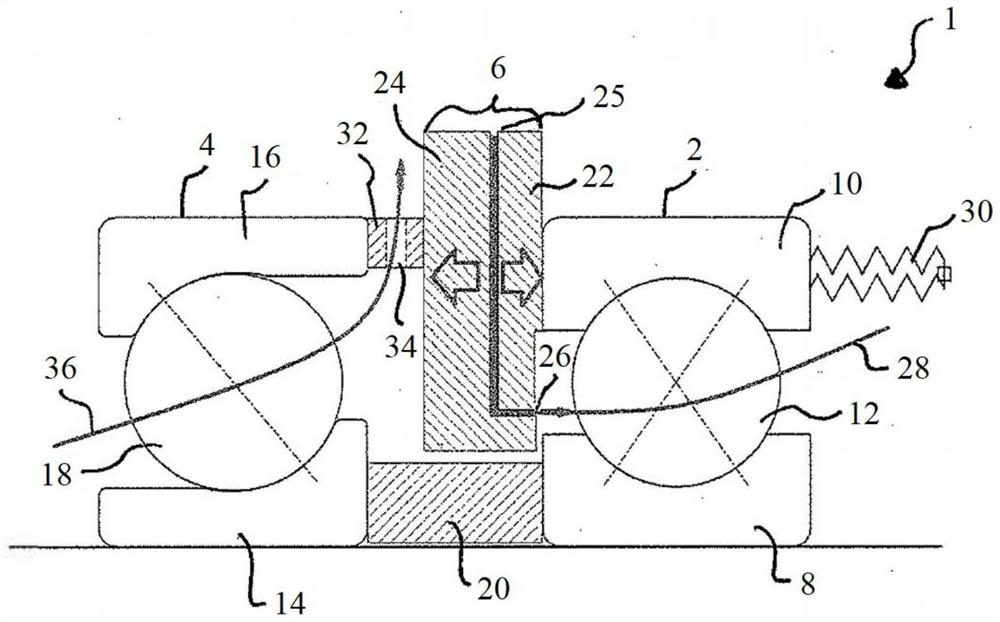

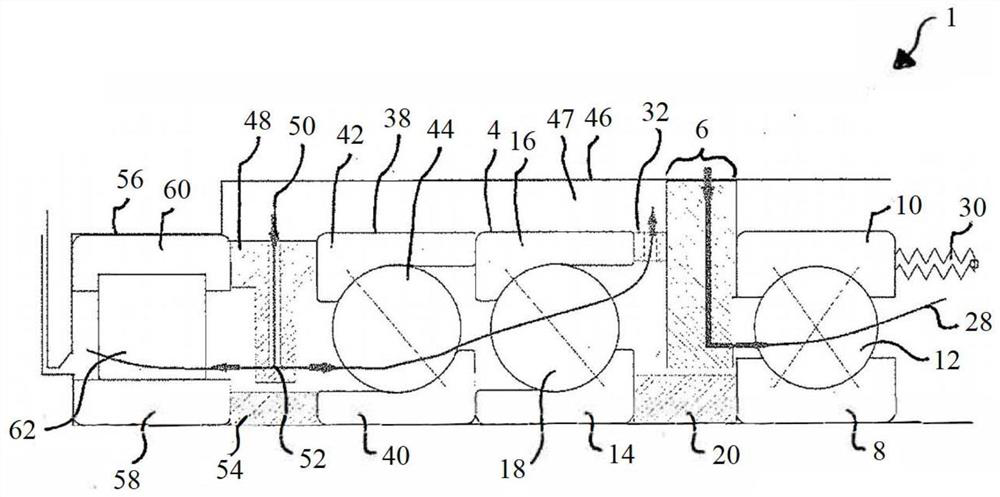

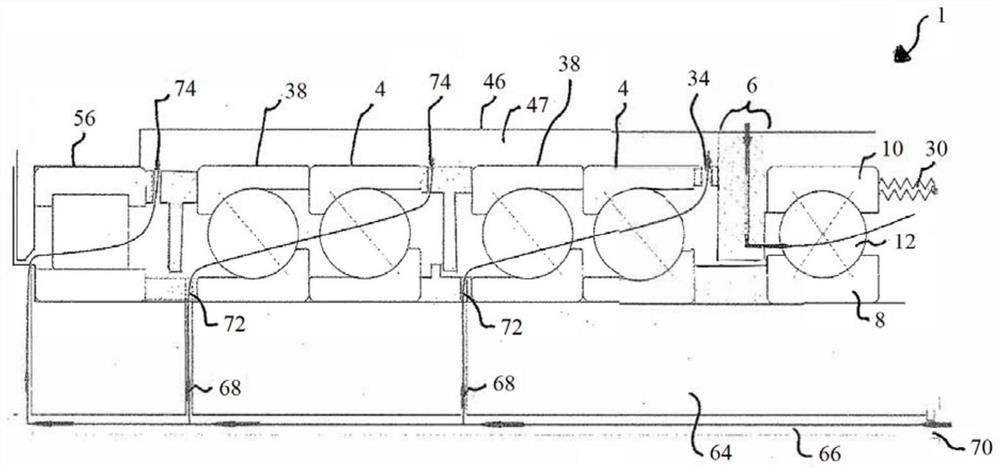

[0082] figure 1 A part of a bearing arrangement 1 is shown, which is shown with two bearings 2 , 4 . A balancing piston 6 is arranged between the two bearings 2 , 4 .

[0083] The bearing 2 is a four-point contact ball bearing with an inner ring 8, an outer ring 10 and rolling elements 12, the rolling elements 12 being balls. Bearing 2 can support axial loads in both directions, and can also support limited radial loads.

[0084] The bearing 4 is a thrust bearing with an inner ring 14, an outer ring 16 and rolling elements 18, which in this case are balls. In this embodiment, the bearing 4 is only subjected to axial loads. Bearing 2 and bearing 4 are separated by a spacer 20 at their inner rings 8 and 14 .

[0085] In order to reduce the forces on the bearing 4 , the bearing arrangement 1 comprises a compensating piston 6 . The balancing piston 6 comprises a first part 22 and a second part 24 . The first part 22 and the second part 24 contact the outer rings 10, 16 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com